Production equipment for polyurethane raw material used for manufacturing soft volleyballs

A production equipment, polyurethane technology, applied in chemical/physical/physical chemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of reducing the service life of the reactor, large clearance between the bushing and the bearing, excessive bearing wear, etc. problems, to achieve the effect of improving the service life, avoiding the use of mechanical structures, and avoiding eccentric rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

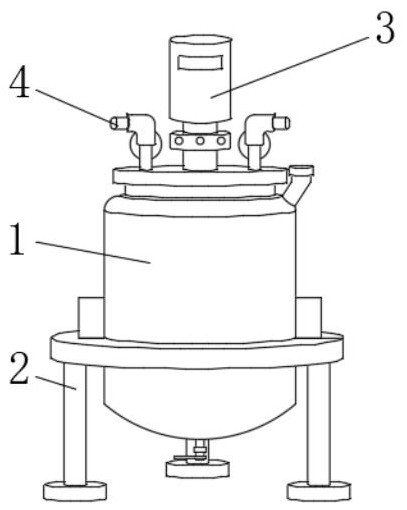

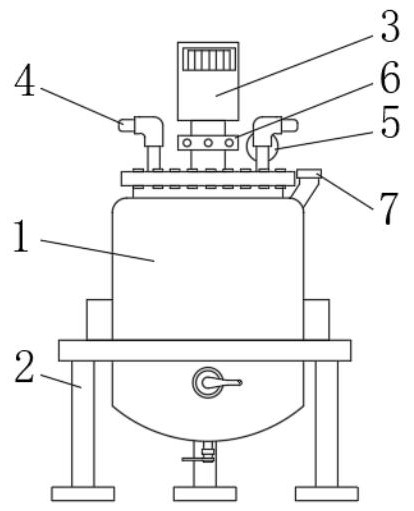

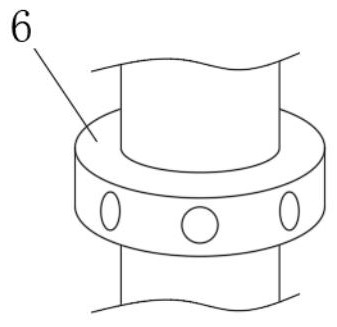

[0034] Embodiment one, by Figure 1-10 Provided, the present invention comprises a kind of polyurethane raw material production equipment for making soft volleyball, comprises housing 1, and the bottom of housing 1 is movably connected with support frame 2, and the top of housing 1 is fixedly connected with motor box 3, and housing The top of the housing 1 is fixedly connected with an air inlet 4; the top of the casing 1 is fixedly connected with a barometer 5, the outer side of the motor box 3 is fixedly connected with a connecting block 6, and the top of the casing 1 is fixedly connected with an air duct 7;

[0035] The inner side of the connection block 6 is movably connected with an output shaft 8, and the inner wall of the connection block 6 is fixedly connected with a warning light 9, and the warning lights 9 are evenly distributed on the inner wall of the connection block 6. The structure of the connection block 6 is a cylindrical structure, and the warning light 9 To r...

Embodiment 2

[0037] Embodiment two, by Figure 1-9 Provided, the present invention comprises a kind of polyurethane raw material production equipment for making soft volleyball, comprises housing 1, and the bottom of housing 1 is movably connected with support frame 2, and the top of housing 1 is fixedly connected with motor box 3, and housing The top of the housing 1 is fixedly connected with an air inlet 4; the top of the casing 1 is fixedly connected with a barometer 5, the outer side of the motor box 3 is fixedly connected with a connecting block 6, and the top of the casing 1 is fixedly connected with an air duct 7;

[0038] The inner side of the connection block 6 is movably connected with an output shaft 8, and the inner wall of the connection block 6 is fixedly connected with a warning light 9, and the warning lights 9 are evenly distributed on the inner wall of the connection block 6. The structure of the connection block 6 is a cylindrical structure, and the warning light 9 To re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com