Method for manufacturing bone tissue slice by decalcification method

A technology for bone tissue and slices, which is applied in the field of microscopic tissue slices, can solve problems affecting pathological diagnosis of diseased tissue or the work of scientific experiments, affecting the staining effect of tissue cells, and affecting the production of bone slices, so as to shorten the transparent time and achieve transparent The effect of enhancing the effect and increasing the toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

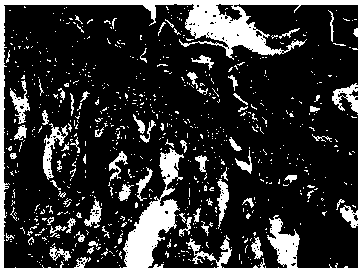

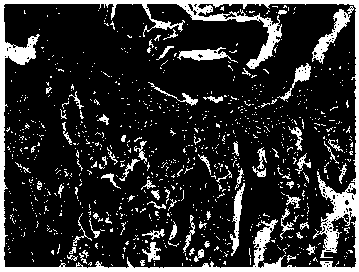

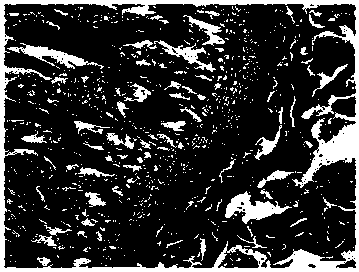

Image

Examples

Embodiment 1

[0033] 1. Configure PBS-EDTA decalcification solution and inorganic acid decalcification solution: ① PBS-EDTA decalcification solution: put 10g EDTA-Na2 and 100ml phosphate buffer solution with a pH of 7.2 on a heating magnetic stirrer for mixing. Add NaOH equivalent solution to the solution, and stir until the white powdery sodium salt is completely dissolved, and then adjust the pH of the mixed solution to 7.2 with dilute hydrochloric acid to obtain a PBS-EDTA solution; Add 8g of calcium chloride into a beaker filled with 100ml of distilled water, vortex and oscillate to mix evenly, and obtain the mineral acid decalcification solution.

[0034] 2. Slicing steps: the first step, fixation: take the bone tissue of the rat, remove the muscle tissue and other tissues around the bone tissue until the surface of the bone tissue is smooth, and then place it in 4% paraformaldehyde prepared by PBS. Fixation; the second step, pre-decalcification: take the bone tissue out of 4% paraformal...

Embodiment 2

[0036] 1. Configure PBS-EDTA decalcification solution and inorganic acid decalcification solution: ① PBS-EDTA decalcification solution: put 12.5g EDTA-Na2 and 100ml phosphate buffer solution with a pH of 7.3 in a heating magnetic stirrer for mixing, and then heat Add NaOH equivalent solution during the process, and stir until the white powdery sodium salt is completely dissolved, and then adjust the pH of the mixed solution to 7.3 with dilute hydrochloric acid to obtain a PBS-EDTA solution; Add 8g of calcium chloride and 8g of calcium chloride into a beaker filled with 100ml of distilled water, vortex and oscillate to obtain the mineral acid decalcification solution.

[0037] 2. Slicing steps: the first step, fixation: take the bone tissue of the rat, remove the muscle tissue and other tissues around the bone tissue until the surface of the bone tissue is smooth, and then place it in 4% paraformaldehyde prepared by PBS. Fixation; the second step, pre-decalcification: the bone ...

Embodiment 3

[0039] 1. Configure PBS-EDTA decalcification solution and inorganic acid decalcification solution: ① PBS-EDTA decalcification solution: put 15g EDTA-Na2 and 100ml phosphate buffer solution with pH 7.4 in a heating magnetic stirrer for mixing, during the heating process Add NaOH equivalent solution to the solution, and stir until the white powdery sodium salt is completely dissolved, and then adjust the pH of the mixed solution to 7.4 with dilute hydrochloric acid to obtain a PBS-EDTA solution; Add 8g of calcium chloride into a beaker filled with 100ml of distilled water, vortex and oscillate to mix evenly, and obtain the mineral acid decalcification solution.

[0040] 2. Slicing steps: the first step, fixation: take the bone tissue of the rat, remove the muscle tissue and other tissues around the bone tissue until the surface of the bone tissue is smooth, and then place it in 4% paraformaldehyde prepared by PBS. Fixation; the second step, pre-decalcification: the bone tissue w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com