Fireproof magnesium oxide board

A magnesium oxide and plate technology, applied in the field of plates, can solve the problems of plate embrittlement, strict requirements on flame retardancy, and the fire prevention effect of modified expanded vermiculite is not as good as that of using, so as to avoid excessive expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

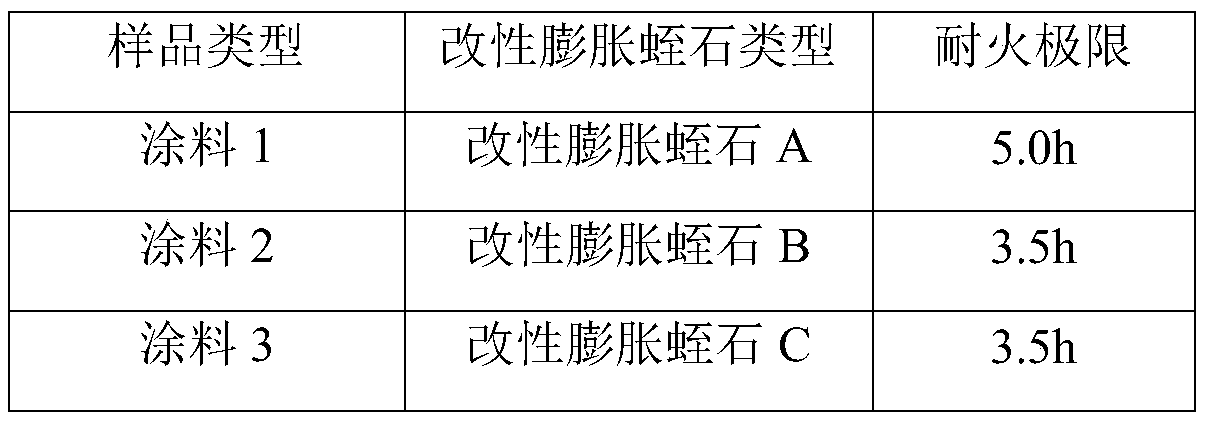

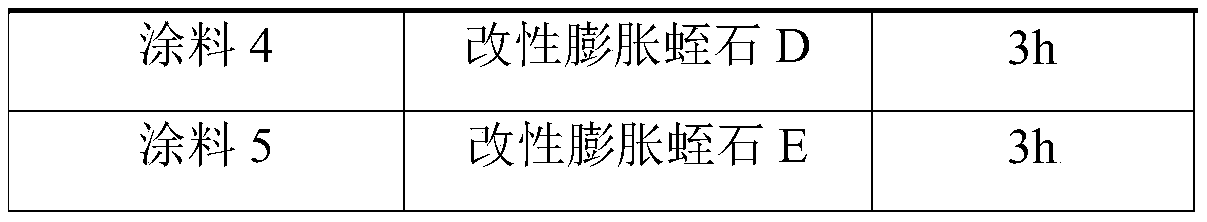

Embodiment 1

[0040] The preparation method of fireproof expanded vermiculite A includes the following steps: (1) Carrying out incomplete expansion calcination to vermiculite: take vermiculite raw material for impurity removal, and put it into a rotary furnace with a temperature of 850° C., heat and expand for 13 seconds, and produce Incomplete expanded vermiculite is obtained after feeding, and its density is that the bulk density is 1050kg / m 3 ;

[0041] (2) Add the incompletely expanded vermiculite to the solvent, fully stir and ultrasonically disperse for 30 minutes to obtain a vermiculite suspension, the solvent is butanol, and the suspension and the carbon-forming catalyst ammonium polyphosphate are added to a closed reaction vessel , heated to 150°C, stirred at high speed and kept warm for 3 hours to obtain a suspension;

[0042] (3) Add fireproof modifier to vermiculite suspension, and carry out ultrasonic dispersion 50 minutes; Wherein, fireproof modifier is made up of low-molecul...

Embodiment 2

[0045] On the basis of embodiment 1, change vermiculite heating expansion time and temperature, make the expanded vermiculite bulk density that step (1) obtains be 850kg / m 3 , the other preparation steps are the same to obtain modified expanded vermiculite B

Embodiment 3

[0047] On the basis of embodiment 1, change vermiculite heating expansion time and temperature, make the bulk density of the expanded vermiculite that step (1) obtains be 2000kg / m 3 , the other preparation steps are the same to obtain modified expanded vermiculite C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com