Built-in channel thermal evaporator and solar water heater with the thermal evaporator

A solar water heater and evaporator technology, which is applied to solar thermal collectors, solar thermal collectors using working fluids, solar thermal energy, etc., can solve problems such as hidden safety hazards, large heat loss, and unfavorable energy conservation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

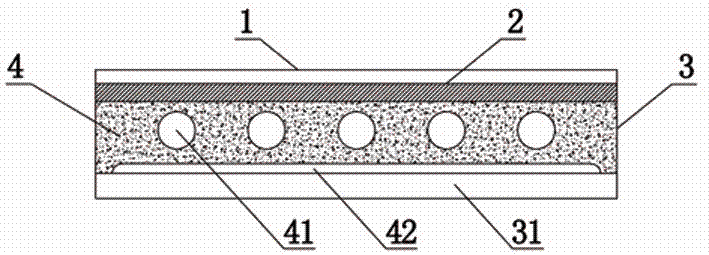

[0023] Such as figure 1 , figure 2 and image 3 As shown, a heat collecting evaporator with a built-in channel includes a thermal insulation shell 3 and an airtight shell arranged inside the thermal insulation shell 3. The shell structure enables the entire heat collecting evaporator to be made into a plate structure, which is suitable for High-rise building installation requirements; the entire solar collector plate is set in a plate type, which is convenient for installing the entire heat collector evaporator on the outer wall of a mid-to-high-rise building, and the overall appearance is beautiful.

[0024] An insulation layer 31 is arranged between the bottom of the airtight casing and the heat-insulating shell 3, and the insulation layer 31 can be arranged to wrap the airtight casing as required, and not cover the upper part of the airtight casing to ensure the absorption of solar heat The upper cover of the airtight housing is provided with a glass cover plate 1, and t...

Embodiment 2

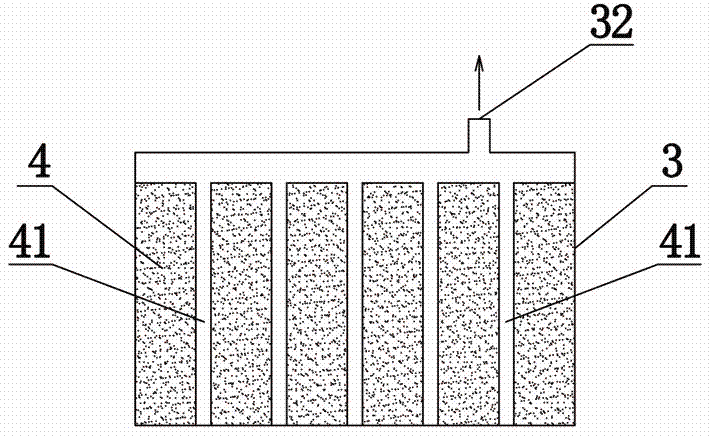

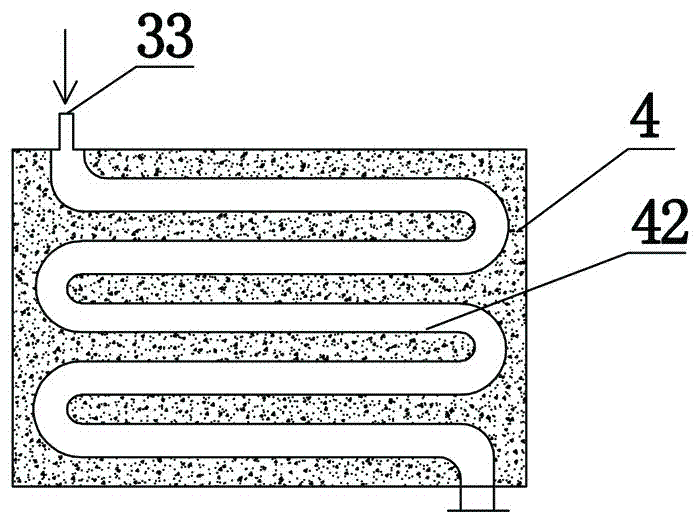

[0031] Such as Figure 4 and Figure 5 As shown, a heat collecting evaporator with a built-in channel includes a thermal insulation shell 3 and an airtight shell arranged inside the thermal insulation shell 3. The shell structure enables the entire heat collecting evaporator to be made into a plate structure, which is suitable for High-rise building installation requirements; the entire solar collector plate is set in a plate type, which is convenient for installing the entire heat collector evaporator on the outer wall of a mid-to-high-rise building, and the overall appearance is beautiful.

[0032] An insulation layer 31 is arranged between the bottom of the airtight casing and the heat-insulating shell 3, and the insulation layer 31 can be arranged to wrap the airtight casing as required, and not cover the upper part of the airtight casing to ensure the absorption of solar heat The upper cover of the airtight housing is provided with a glass cover plate 1, and the glass co...

Embodiment 3

[0039] Such as Figure 6 As shown, a solar water heater includes a heat collecting evaporator 6, a water storage tank 8, a condenser 9 arranged in the water storage tank 8, and a loop pipeline 7, thereby forming a split solar water heater, which is suitable for middle and high-rise buildings building needs. The gas-phase outlet of the heat-collecting evaporator 6, the loop pipe 7, the inlet and outlet of the condenser 9 and the liquid-phase inlet of the heat-collecting evaporator 6 are sequentially connected to form a heat circulation delivery loop.

[0040] The heat-collecting evaporator 6 used in this embodiment is the flat-plate heat-collecting evaporator in the above-mentioned embodiment 1 or embodiment 2, and the circulation of the heat circulation conveying circuit can carry out the circulating conveying of the working medium without other power. Specific working principle: use the heat collecting evaporator 6 to absorb solar radiation, heat the liquid working medium in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com