Modified halloysite nanotube for proton exchange membrane and preparation method of modified halloysite nanotube

A technology of halloysite nanotubes and proton exchange membranes, which is applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, and can solve problems such as reducing proton conductivity and fuel methanol penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Dissolve 0.5mmol Tris-hydrochloric acid in 50ml deionized water, adjust to pH = 8.5 with 0.01mol / L NaOH, add 2g HNTs and 0.5mmol dopamine hydrochloride, sonicate for 30min, magnetically stir for 4h, centrifuge with deionized water Wash and dry at 30-50°C to obtain D-HNTs;

[0031] In a 50ml three-necked flask, pass argon gas to remove water vapor, add 20ml THF, 1ml triethylamine, 1.5g D-HNTs, 3ml 2-bromo-2-methylpropionyl bromide (BIBB), and stir the reaction for 8h with a magnet, and then use Acetone and methanol aqueous solution with a volume fraction of 50% were ultrasonically cleaned, dried at 30-50°C to obtain Br-HNTs;

[0032] In a 50ml three-neck flask, pass argon to remove the air, add 10ml N-N dimethylformamide (DMF), 10ml deionized water, 40mmol NaSS, 2mmol CuBr, 2mmol CuBr 2 , 2mmol hexamethyltriethylenetetramine, 1.5g Br-HNTs, magnetically stirred and reacted for 24h, followed by ultrasonic centrifugation with acetone and methanol aqueous solution with a vo...

Embodiment 2

[0035] Dissolve 0.5mmol Tris-hydrochloric acid in 50ml deionized water, adjust to pH=8.5 with 0.01mol / L NaOH, add 2g halloysite and 0.5mmol dopamine hydrochloride in sequence, ultrasonicate for 30min, and magnetically stir for 10h, wash and dry Get D-HNTs;

[0036] In a 50ml three-necked flask, pass argon gas to remove water vapor, add 20ml THF, 1ml triethylamine, 1.5g D-HNTs, 3ml BIBB, stir the reaction for 24 hours with a magnet, wash and dry to obtain Br-HNTs;

[0037] In a 50ml three-neck flask, pass argon gas to remove the air, add 10ml DMF, 10ml deionized water, 40mmol NaSS, 2mmol CuBr, 2mmol CuBr 2 , 2mmol of hexamethyltriethylenetetramine, 1.5g of Br-HNTs, stirred by a magnet for 48 hours, washed and dried to obtain NaSS-modified halloysite nanotubes NaSS-HNTs.

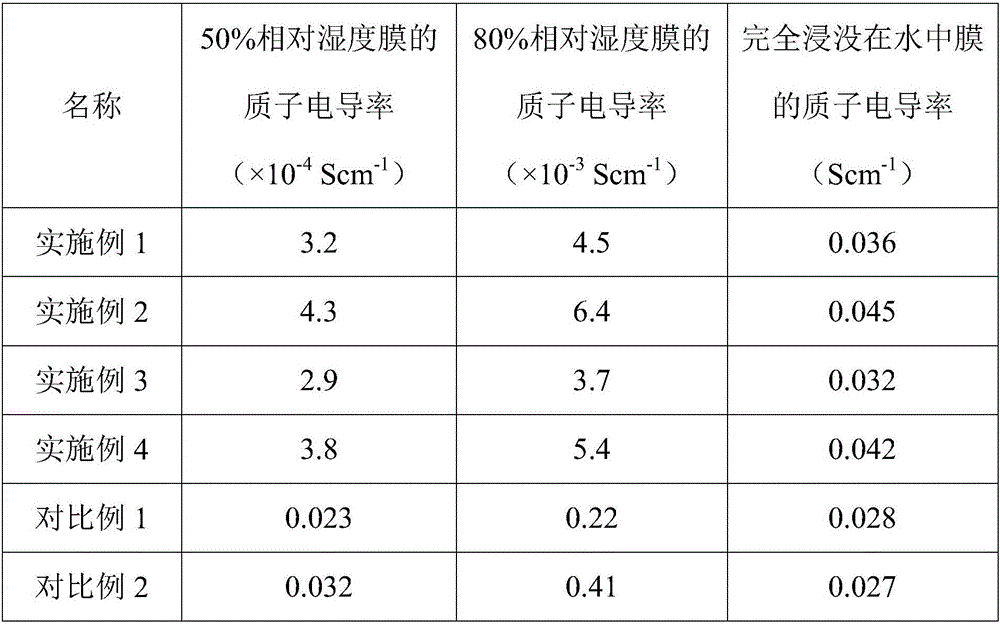

[0038] The above-mentioned NaSS-modified halloysite nanotubes were doped into the proton exchange membrane and tested for its proton conductivity. The results are shown in Table 1. The film forming process i...

Embodiment 3

[0040] Dissolve 0.5mmol Tris-hydrochloric acid in 50ml deionized water, adjust the pH to 8.5 with 0.01mol / L NaOH, add 2g halloysite and 0.5mmol dopamine hydrochloride in sequence, ultrasonicate for 30min, and stir for 4h with a magnet, after washing and drying Get D-HNTs;

[0041] In a 50ml three-necked flask, pass argon gas to remove water vapor, add 20ml THF, 1ml triethylamine, 1.5g D-HNTs, 3ml BIBB in sequence, stir the reaction for 8 hours with a magnet, wash and dry to obtain Br-HNTs;

[0042] In a 50ml three-neck flask, pass argon gas to remove the air, and then add 10ml DMF, 10ml deionized water, 40mmol AMPS, 2mmol CuBr, 2mmol CuBr 2 , 2mmol hexamethyltriethylenetetramine, 1.5g Br-HNTs, magnetically stirred and reacted for 24h, washed and dried to obtain AMPS-modified halloysite nanotube AMPS-HNTs.

[0043] The above-mentioned AMPS-modified halloysite nanotubes were doped into the proton exchange membrane and tested for its proton conductivity. The results are shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com