Refrigeration cycle device

A circulation device and refrigerant technology, applied in the direction of gas cycle refrigerators, irreversible cycle compressors, reversible cycle compressors, etc., can solve the problems of unstable rotation of expanders, achieve stable rotation, and prevent over-expansion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

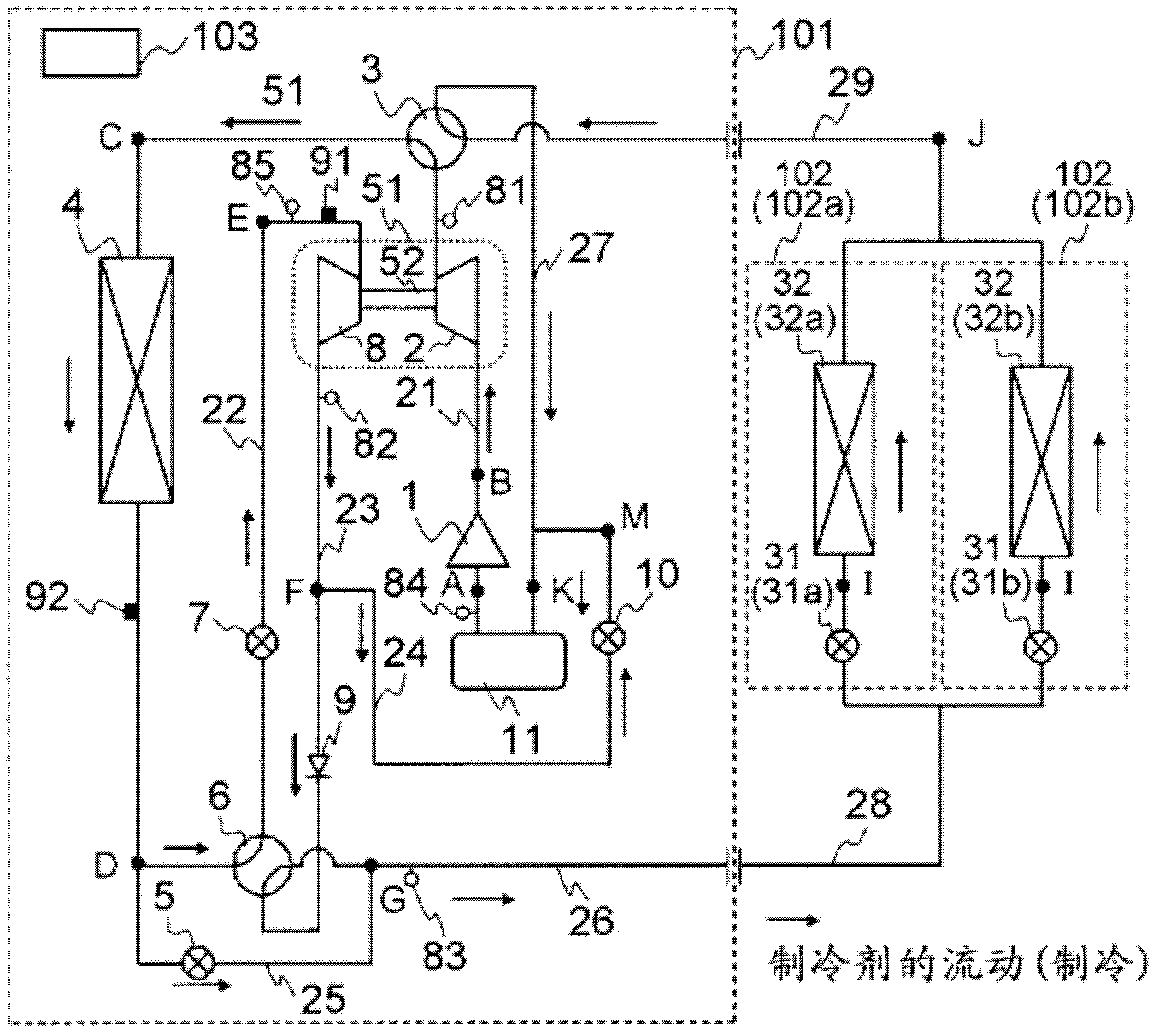

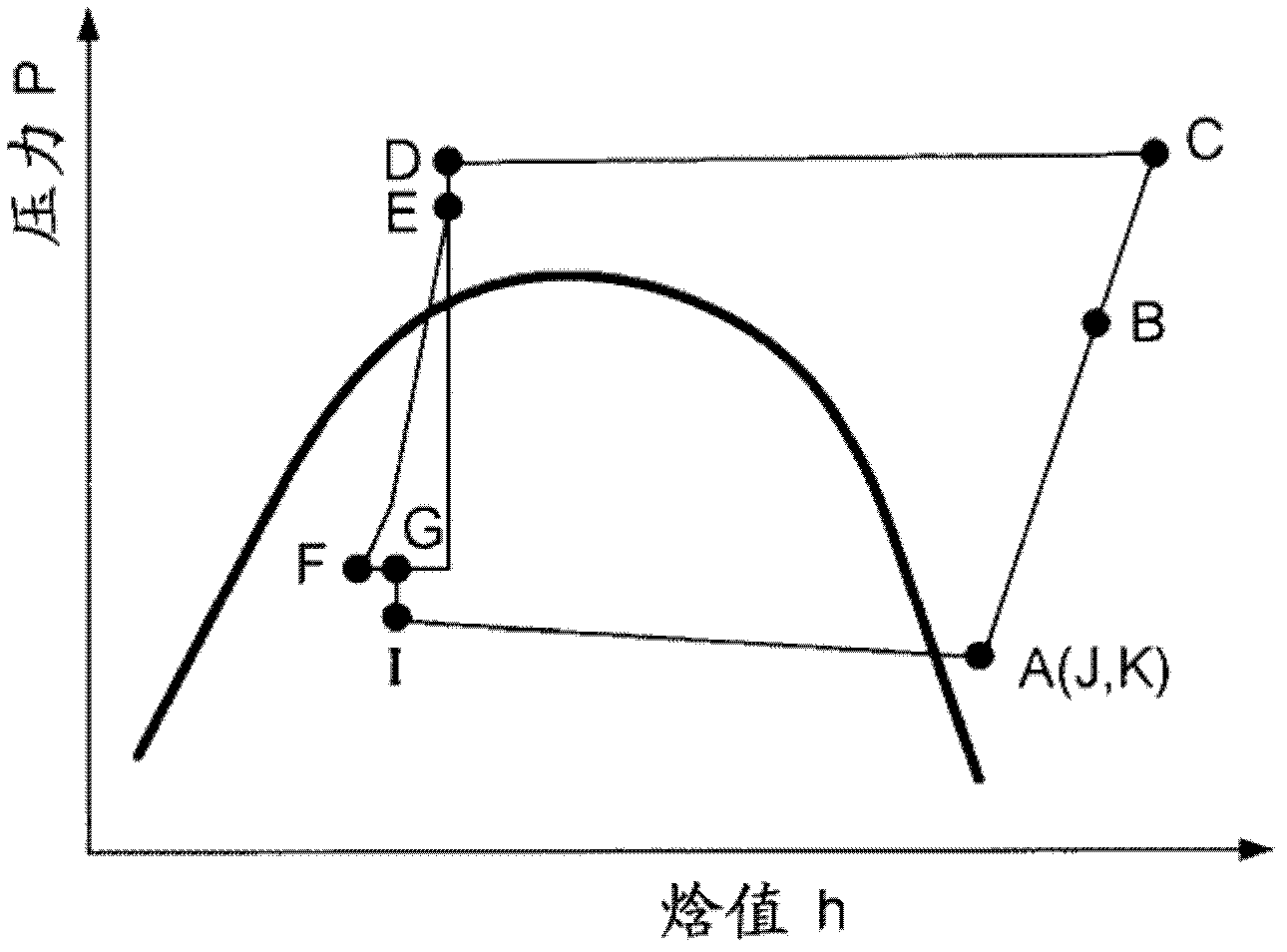

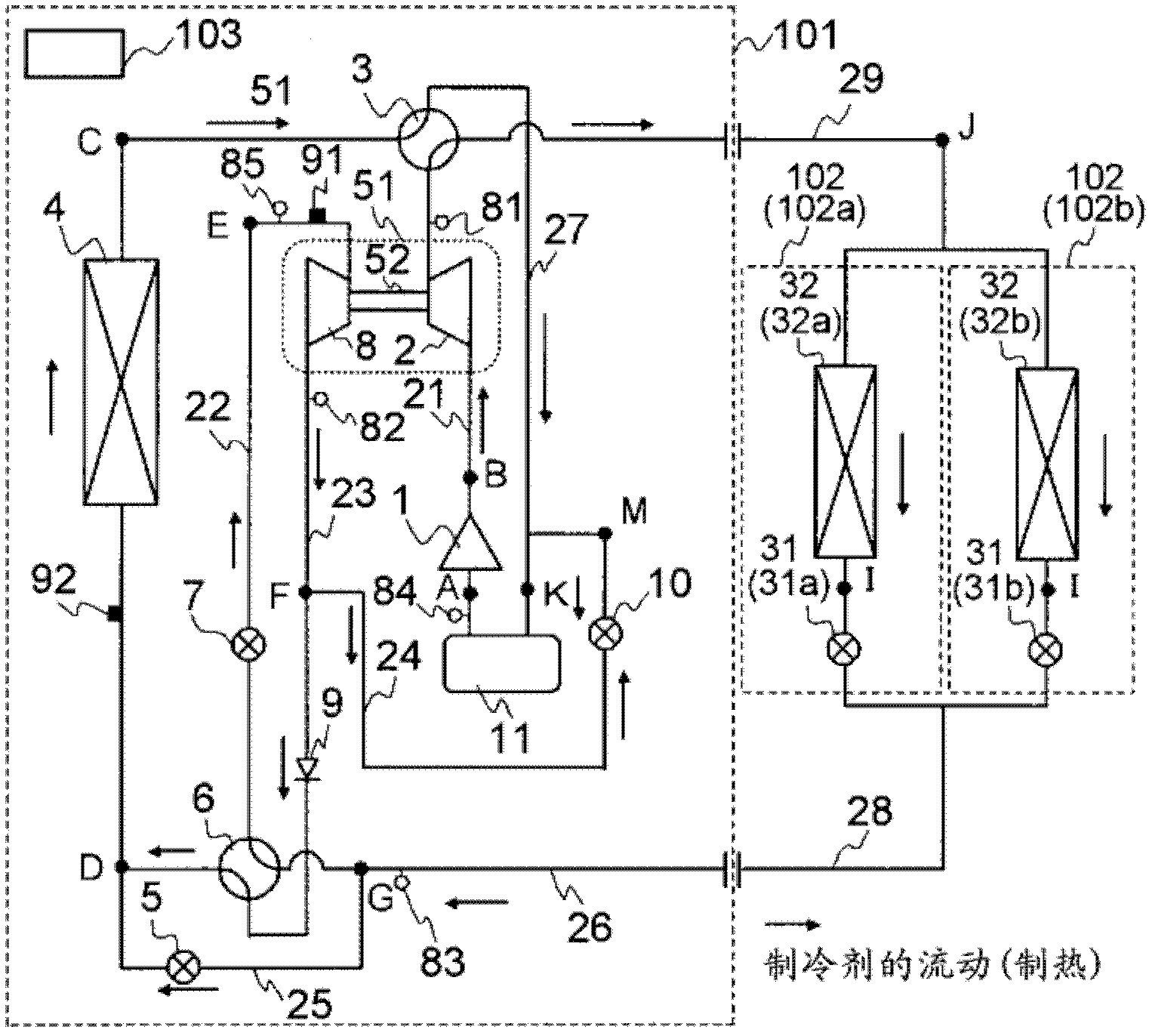

[0031] figure 1 It is a refrigerant circuit diagram at the time of cooling operation of the air conditioner equipped with the refrigeration cycle apparatus concerning 1st Embodiment of this invention. figure 2 yes figure 1 Refrigerant circuit diagram of the air conditioner in cooling operation.

[0032] figure 1 The air conditioner has a refrigerating cycle device, and the refrigerating cycle device is sequentially connected to the first compressor driven by the motor and compressing the refrigerant, the second compressor, and the outdoor heat exchanger 4 through piping, so that the refrigerant passing through the interior is expanded and transferred from the refrigerant An expander 8 for recovering power and an indoor heat exchanger 32 . The second compressor 2 and the expander 8 are connected through the drive shaft 52 , the power is recovered by the expander 8 , and the power is used to drive the second compressor 2 through the drive shaft 52 .

[0033] The outdoor ...

no. 2 approach

[0143] The first embodiment described above is designed to prevent the expander 8 from becoming over-expanded during operation. The second embodiment is designed to prevent the expander 8 from becoming overexpanded when the air conditioner is started.

[0144] Figure 15 It is a flowchart showing the operation of preventing overexpansion of the expander 8 according to the second embodiment of the present invention. in addition, Figure 16 It is a graph showing a change in high pressure and a change in discharge pressure of an expander when the air conditioner is started. exist Figure 16 In , the dotted line indicates the case where the operation for preventing the overexpansion of the expander 8 is not performed. exist Figure 16 In the figure, the solid line represents the case where the action to prevent the over-expansion of the expander 8 is performed, that is, the Figure 15 The control situation shown. Here, in the description Figure 15 before the flowchart of ...

no. 3 approach

[0156] In the above-described first and second embodiments, the refrigerant discharged from the first compressor 1 is directly sucked into the second compressor 2 . In the third embodiment, the refrigerant discharged from the first compressor 1 is sucked into the second compressor 2 after being cooled by the intercooler 4 a. In addition, as an action to prevent overexpansion of the expander 8 Figure 11 and Figure 15 In terms of the control shown, the third embodiment is the same as the first embodiment and the second embodiment.

[0157] Figure 17 It is a refrigerant circuit diagram during cooling operation of the air conditioner of the third embodiment. A refrigerant heat exchanger 14 is provided for bypassing the refrigerant from the discharge pipe 23 of the expander 8 to the inlet pipe of the accumulator 11 (refrigerant returned to the first compressor 1 through the first bypass valve 10 ). ) exchanges heat with the refrigerant (refrigerant bypassed from the main rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com