Self-drainage sewage pipe

A sewage pipeline and self-draining technology, which is applied to the sewer system, cleaning the sewer, water/sludge/sewage treatment, etc. It can solve the problems of inconvenient post-processing, high pressure of sewage filtration, and large economic cost, and reduce sewage. Treatment pressure, effect of reducing discharge pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

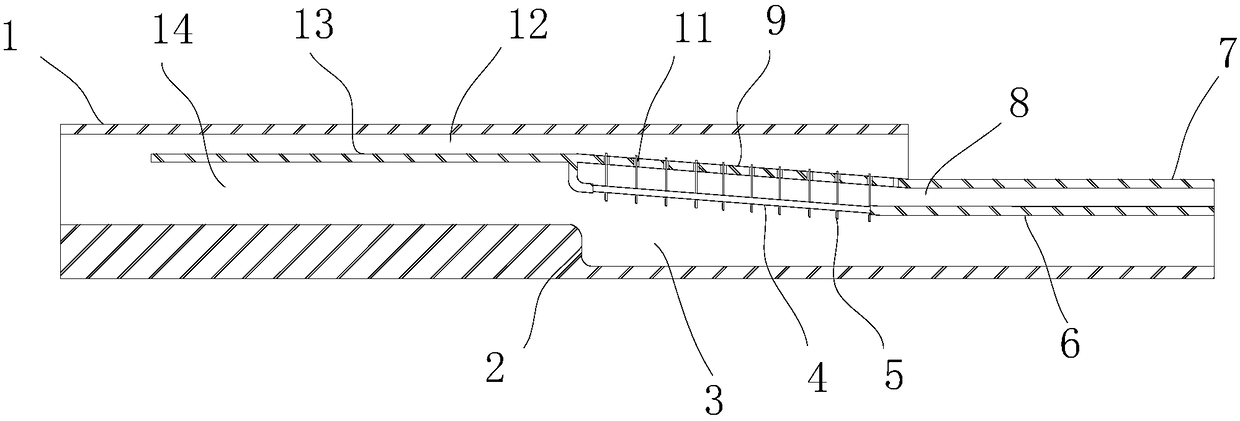

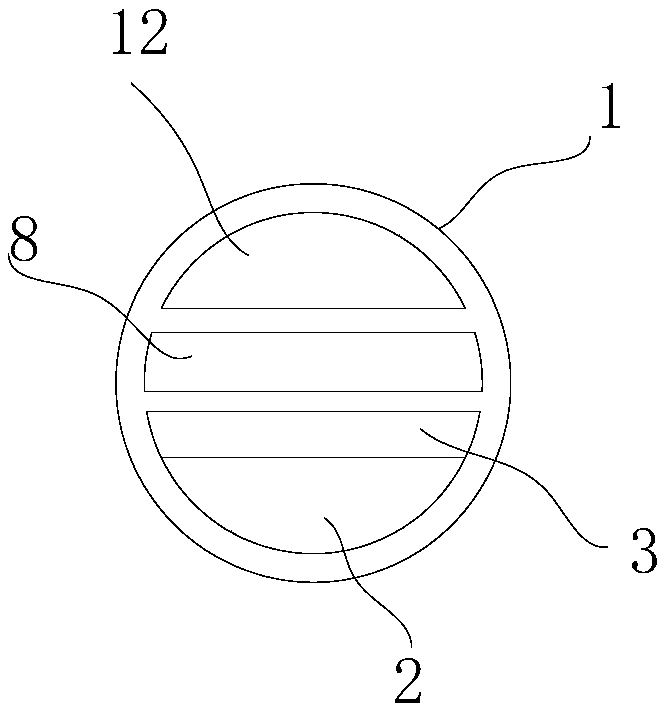

[0016] Such as figure 1 with figure 2 As shown, the self-draining sewage pipeline includes a pipe body part 1 and an extension section 7 arranged on one side of the pipe body part 1. A sewage channel is arranged in the middle of the pipe body part 1, and a first sewage channel is provided in the middle of the sewage channel near the mouth of the sewage channel. A partition 13, the first partition 13 divides the entire sewage channel into a sewage chamber 12 at the upper end and a first drainage chamber 14 at the bottom;

[0017] The output end of the first dividing plate 13 has a filter section 9, and the bottom output end of the filtering section 9 connects the extension section 7, and the bottom of the filtering section 9 is provided with a second dividing plate 6, and the second dividing plate 6 and the filtering section at the upper end 9 and the extension section 7 form a closed intermediate cavity 8;

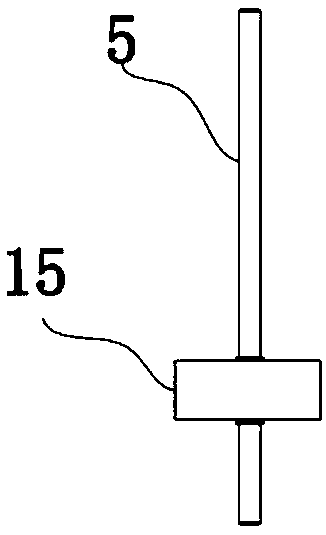

[0018] Wherein, the bottom of the middle cavity 8 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com