Glass fiber kiln waste gas treatment device and method

A technology of waste gas treatment device and glass fiber kiln, which is applied in waste heat treatment, furnace monitoring device, descaling device, etc., can solve the problems of inability to accurately control kiln pressure by manual plug-in valve, difficulty in glass bubble removal, and high kiln pressure, etc. Achieve the effect of improving equipment safety, reducing equipment investment, ensuring temperature and production operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

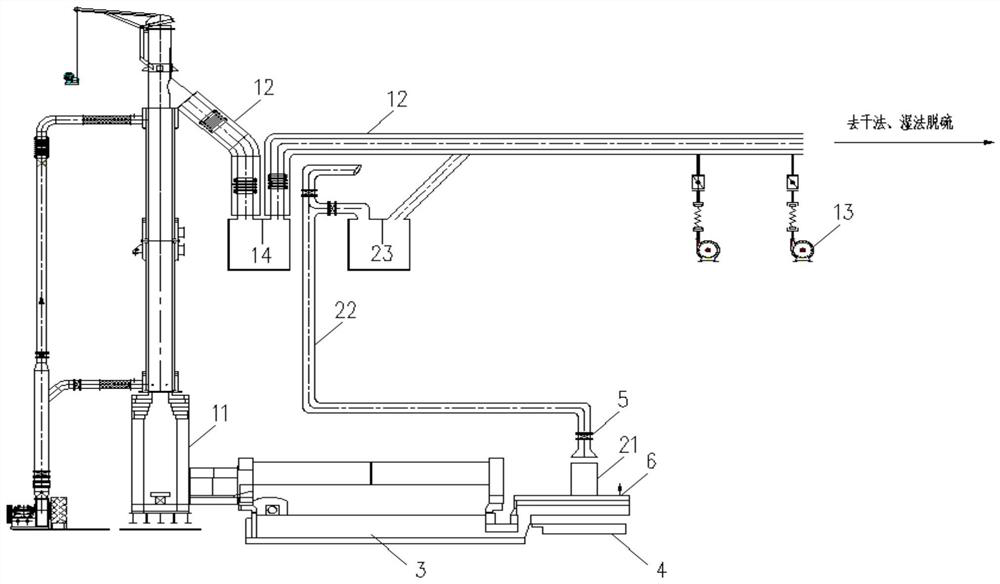

[0023] In order to better understand a kind of glass fiber kiln waste gas treatment device and method of the present invention, the following will pass the attached figure 1 and examples in detail.

[0024] Aiming at the technical problems of direct discharge of E-glass formula kiln waste gas, polluting the environment, and the inability of the manual slide valve to accurately control the kiln pressure, resulting in technical problems such as high kiln pressure, difficulty in glass defoaming, and increased fuel input in the forming area, the inventors Through design and practice, after a one-year follow-up and summary, the following industrial design that can be promoted and applied has been achieved.

[0025] A fiberglass kiln exhaust gas treatment device is based on the existing kiln exhaust gas treatment device, and a molding area exhaust gas treatment device is added. The kiln exhaust gas treatment device includes a refractory chimney 11 in the melting section, a kiln exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com