Preparation method for hydroxycalcium carbonate and application of hydroxycalcium carbonate in animal feed field

A technology of calcium hydroxycarbonate and animal feed, which is applied in the molding or processing of animal feed, animal feed, calcium carbonate/strontium/barium, etc., can solve the problems of unreported application, unfavorable reaction amount, uncontrollable amount, etc. Simple, uniform product particle, process controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A preparation method for calcium hydroxycarbonate, comprising the following steps:

[0053] Add 113g of calcium chloride and 114g of calcium oxide with a purity of 98% into 1.3L of water, cool down, add 171g of sodium bicarbonate with a purity of 98% under stirring and react at a constant temperature at -1°C for 1h, and react After the crystallization was completed for 1 h, after centrifugal filtration, it was dried and pulverized in an oven at 105° C. to obtain 258 g of calcium hydroxycarbonate.

[0054] The target product hydroxycalcium carbonate obtained by the present invention is detected, wherein the carbonate ion content is 43.2%, the calcium content is 43.3%, the hydroxide content is 12.2%, and the volatile substance content is 0.6% at 105° C., the detection result Calcium Hydroxycarbonate Molecular Formula Ca 3 (CO 3 ) 2 (OH) 2 match. The product yield is 93.2%, and the product purity is 98.7%.

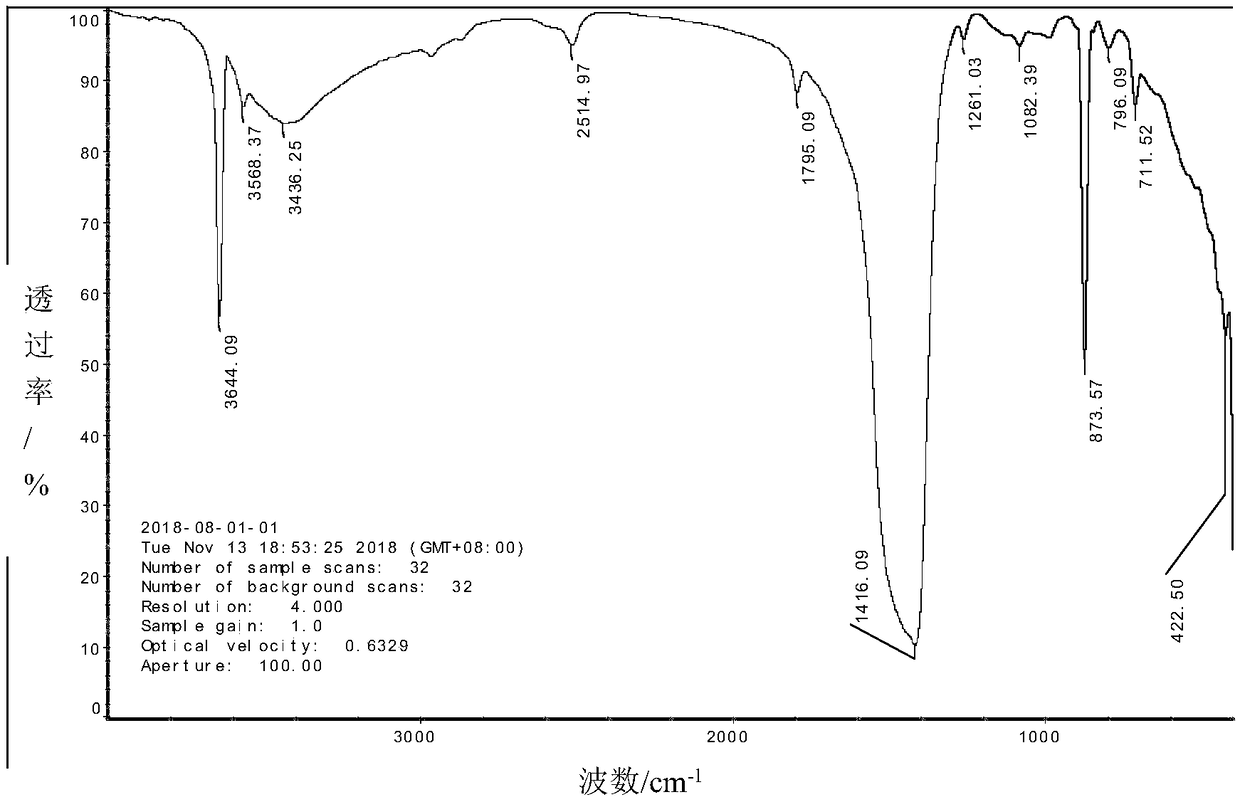

[0055] Product infrared spectrum see figure 1 ,Depend on ...

Embodiment 2

[0057] A preparation method for calcium hydroxycarbonate, comprising the following steps:

[0058] Add 113kg of calcium chloride and 114kg of calcium oxide with a purity of 98% to 1 ton of water, cool down, add 204kg of potassium bicarbonate with a purity of 98% under stirring and react at a constant temperature at -3°C for 1.0h. After the completion of the crystallization at room temperature for 50 minutes, after centrifugal filtration and flash drying, 2% modified starch was added to granulate and pass through a 100-mesh sieve to obtain 273 kg of calcium hydroxycarbonate.

[0059] The target product hydroxycalcium carbonate obtained by the present invention is detected, wherein the carbonate ion content is 41.7%, the calcium content is 41.7%, the hydroxide content is 11.8%, and the volatile substance content is 3.6% at 105° C., the detection result Calcium Hydroxycarbonate Molecular Formula Ca 3 (CO 3 ) 2 (OH) 2 match. The product yield is 94.8%, and the product purity ...

Embodiment 3

[0061] A preparation method for calcium hydroxycarbonate, comprising the following steps:

[0062] Add 156kg of calcium hydroxide with a purity of 98% to 1 ton of water, lower the temperature, add 164kg of calcium bicarbonate with a purity of 99% under stirring and react at a constant temperature of 1°C for 1.0h, after the reaction, cool down to room temperature for crystallization After 45 minutes, it was centrifugally filtered, dried in an oven at 105°C, and crushed through 30 meshes to obtain 271kg of calcium hydroxycarbonate.

[0063] The target product hydroxycalcium carbonate obtained by the present invention is detected, wherein the carbonate ion content is 42.7%, the calcium content is 42.8%, the hydroxide content is 12.1%, and the volatile substance content is 1.3% at 105° C., the detection result Calcium Hydroxycarbonate Molecular Formula Ca 3 (CO 3 ) 2 (OH) 2 match. The product yield is 96.5%, and the product purity is 97.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com