Battery injection and formation control device

A control device and battery technology, applied in secondary battery manufacturing, battery pack components, circuits, etc., can solve problems such as difficulty in sealing and difficult control of battery pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

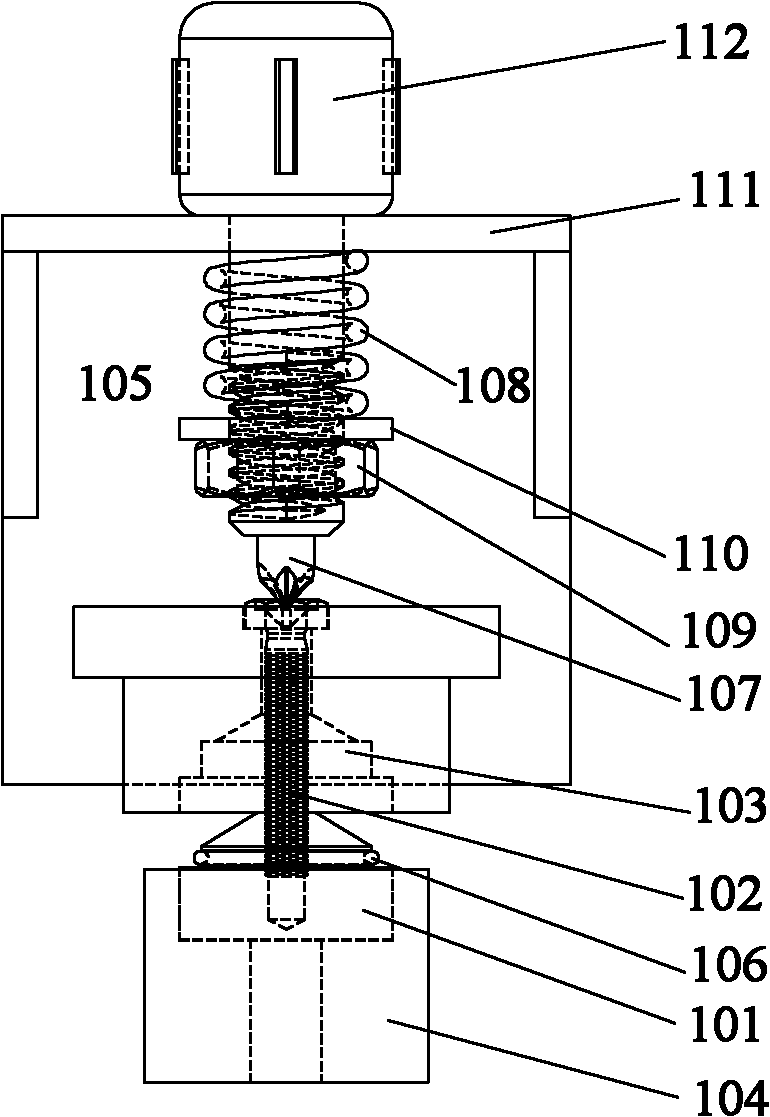

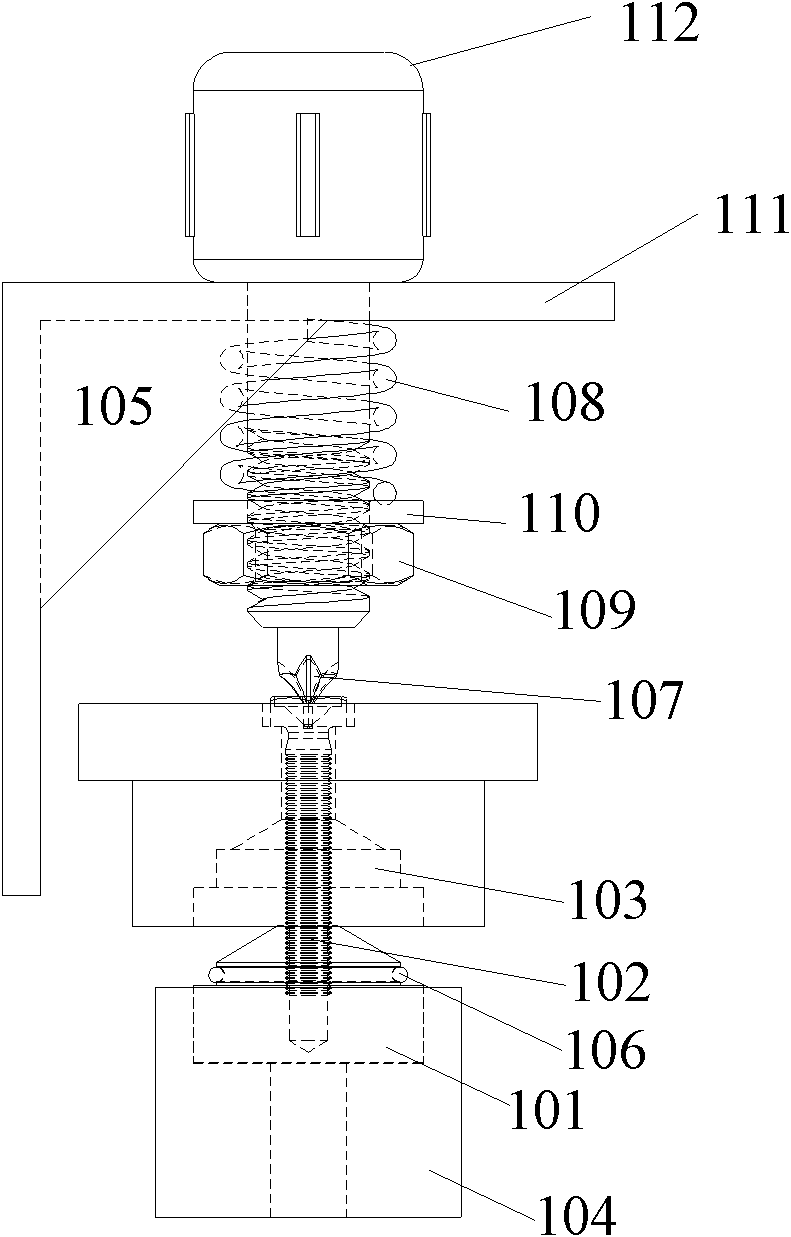

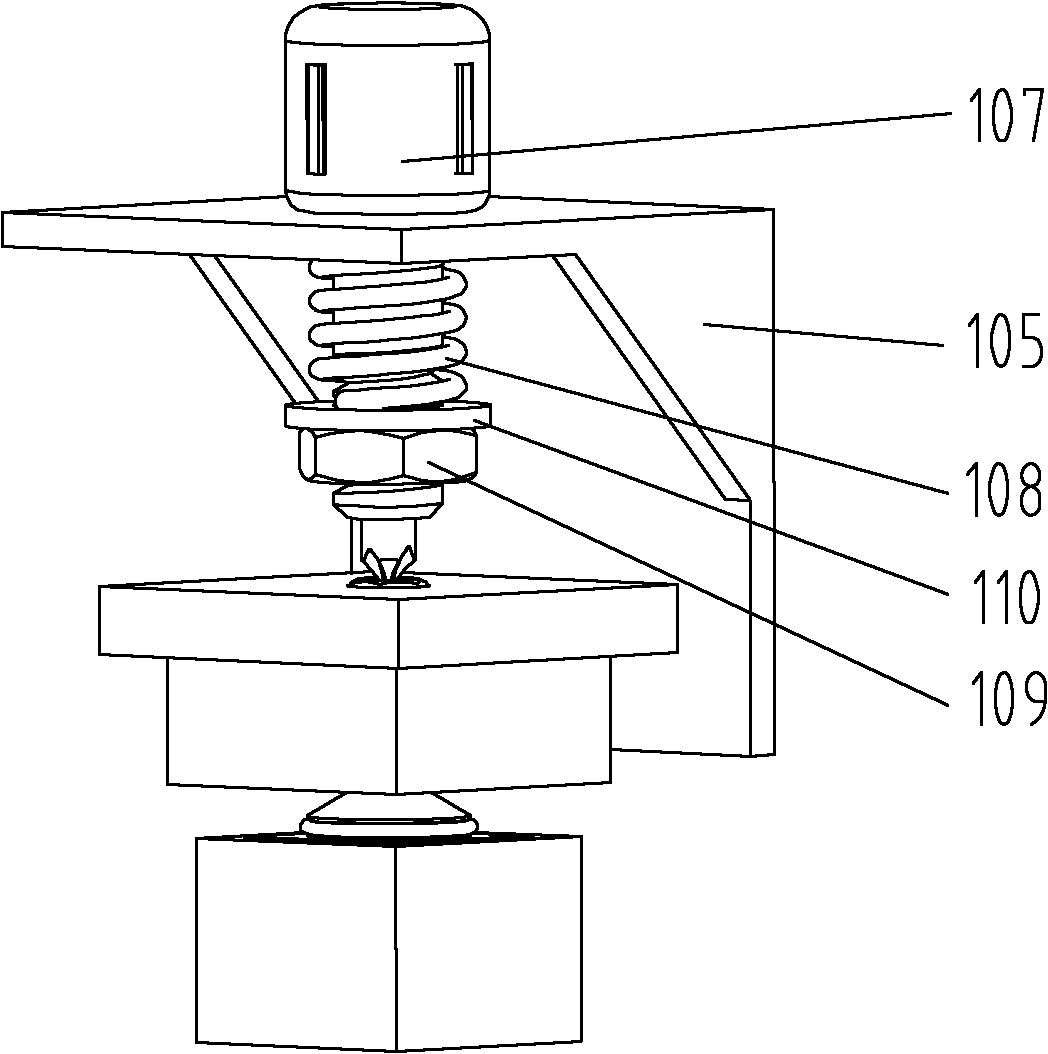

[0028] A battery liquid injection and formation control device consists of an inner piston 101, an outer piston 102, a liquid injection hole 103 on the cover plate of the battery case, a plastic bracket 104 in the battery case, and a piston capable of controlling the gas discharge pressure. The device 105 is composed. The inner piston 101 is placed in the plastic bracket 104, and the inner piston 101 is provided with a screw hole matched with the outer piston 102. The screw hole and the liquid injection hole 103 are aligned with each other, and the outer piston 102 passes through the liquid injection hole 103 and the inner piston 101. The threaded connection closes the injection hole.

[0029] The piston packaging device 105 is composed of a support frame 111 , a screwdriver 107 with thread, a spring 108 , a washer 110 and a nut 109 . Screwdriver 107 passes support frame 111, and its handle 112 is above support frame 111, and screwdriver 107 is covered with spring 108 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com