Self-pressed suction oxygen-aeration blow-off pipe

A technology of water discharge pipe and suction chamber, which is applied in the field of self-pressurized air suction and oxygen enhancement water discharge pipe, which can solve the problems of large pressure head loss, uneven stress distribution, unfavorable gas inhalation, etc., achieve broad market prospects and improve suction efficiency , the effect of a reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

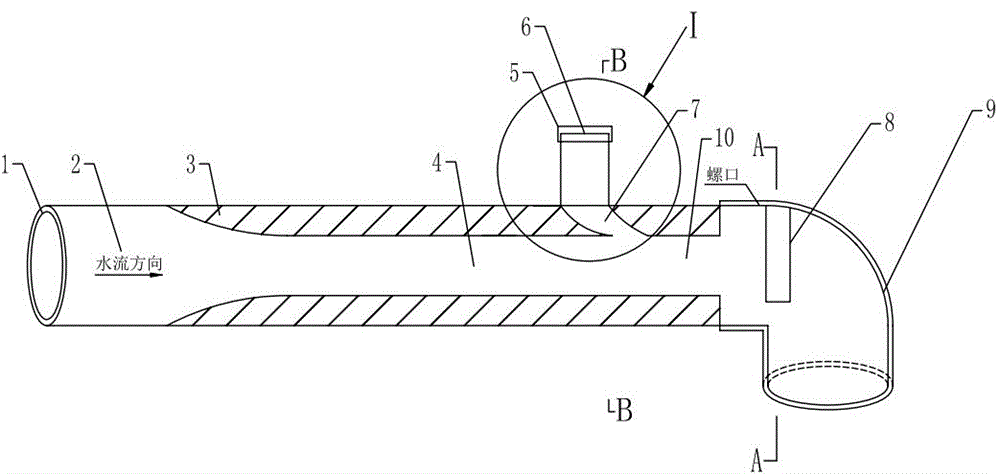

[0026] Combine below Figure 1 to Figure 4 The specific structure of the self-pressurized air-breathing oxygen-increasing water discharge pipe in the first embodiment of the present invention will be described in detail.

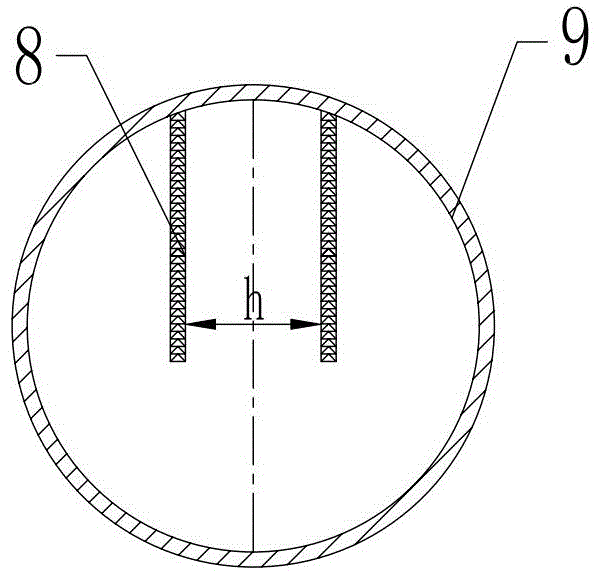

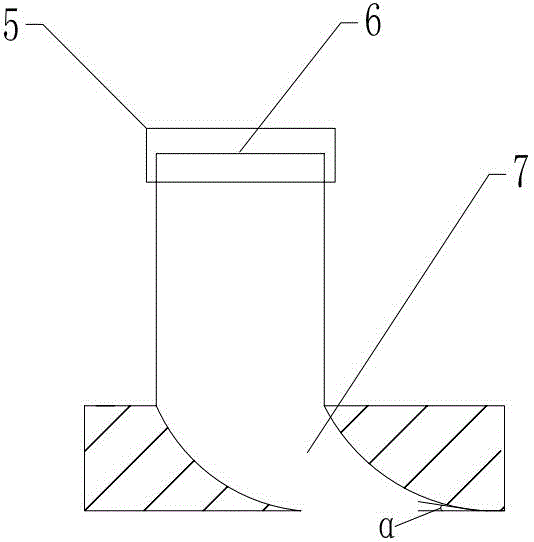

[0027] exist Figure 1 to Figure 4 The self-pressurized air-breathing oxygen-increasing water discharge pipe shown in the first embodiment of the present invention includes a water inlet section 2, a contraction section 3, a throat pipe 4, an aeration and oxygen-increasing section 10 and an elbow 9, and the front end of the water inlet section 2 A screw port 1 for connecting a high-pressure water pipe is provided; the inner diameter of the shrinkage section 3 decreases gradually along the water flow direction, and its length is the same as the inner diameter of the throat pipe 4; the upper part of the throat pipe 4 near the aeration and oxygenation section 10 has a longitudinal section of An arc-shaped air suction chamber 7, the upper part of which is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com