Extractor hood

A range hood and flue gas technology, which is applied in the direction of removing oil fume, household heating, lighting and heating equipment, etc. It can solve the problems of large flow loss and increased wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

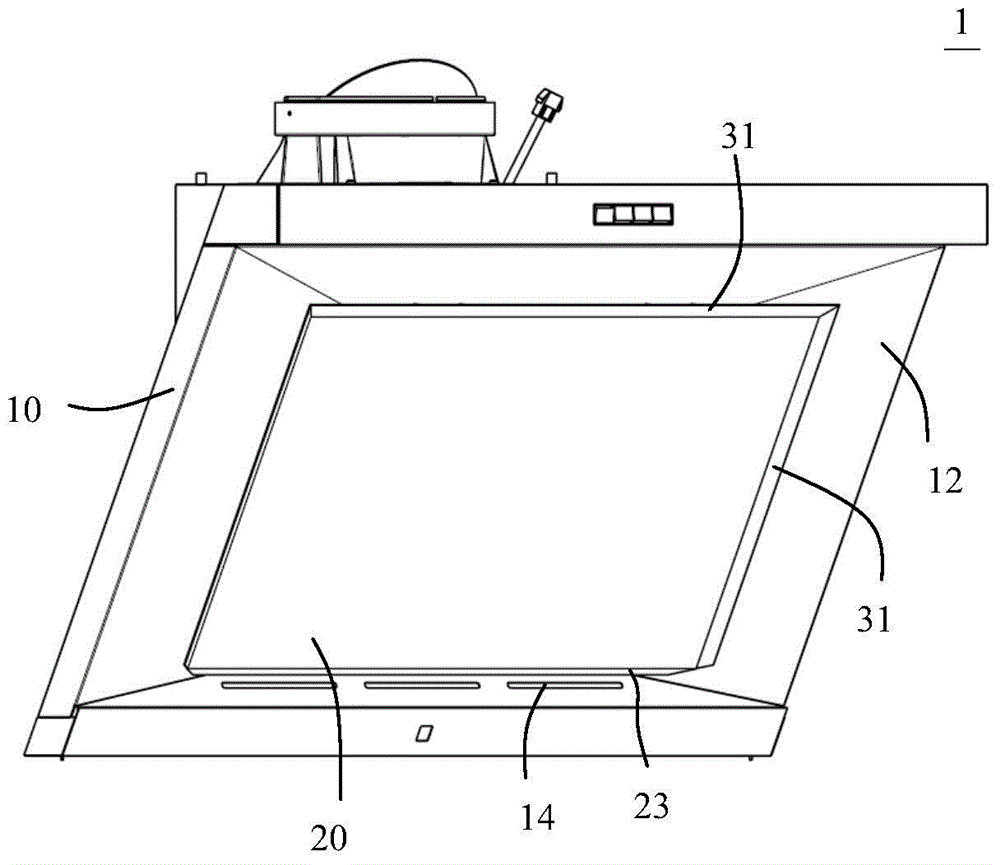

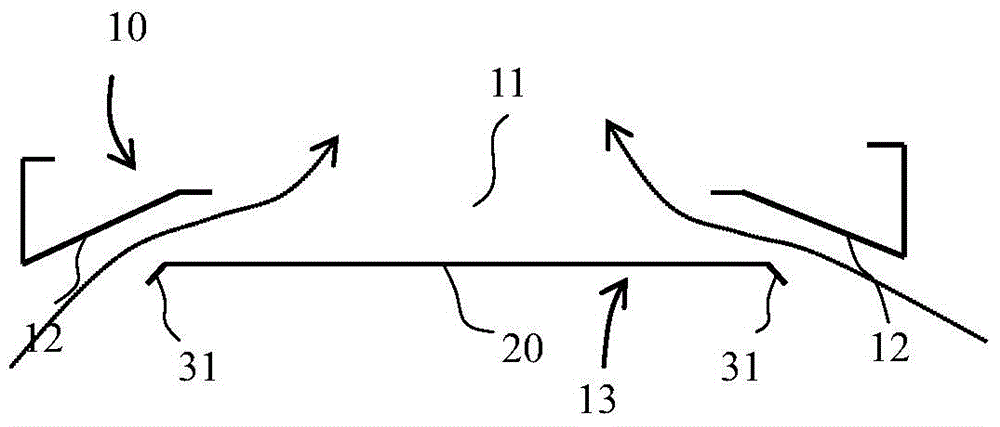

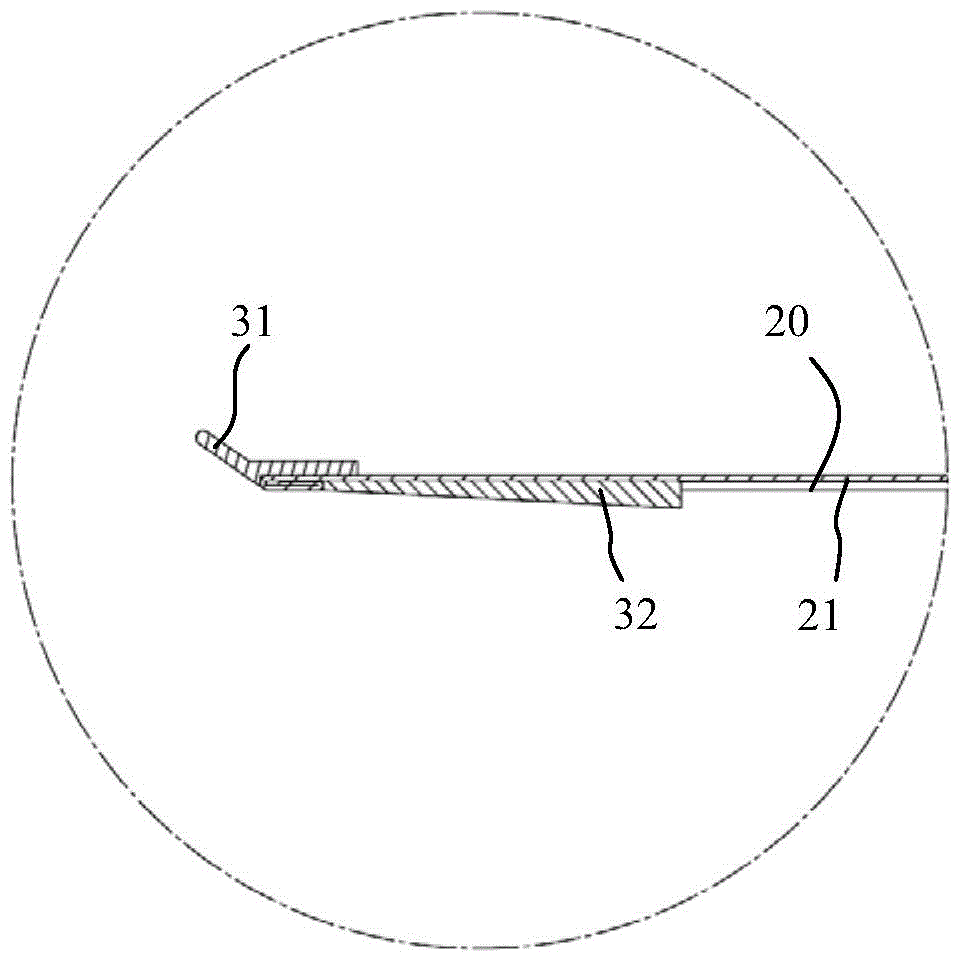

[0037] The present invention provides a range hood. Although a side-suction range hood is used as an example for illustration in the specification and drawings, the present invention is not limited thereto. like figure 1 , figure 2 as shown, figure 1 It is a perspective view of a range hood according to an embodiment of the present invention, figure 2 It is a schematic diagram of a smoke guide plate and a smoke collection hood according to an embodiment of the present invention. The range hood 1 includes a smoke collecting hood 10 and a smoke guide plate 20. There is a gap between the smoke collecting hood 10 and the outer edge of the smoke guide plate 20 for smoke to pass through. Resistance deflector.

[0038] like figure 1 As shown, the range hood 1 of this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com