Centralized conveying synergetic system for lubricating grease

A synergistic system and grease technology, which is applied in the delivery system of No. 4 grease, high-viscosity grease (3 fields), can solve the problems of low cone penetration, high viscosity of grease, and difficulty in realizing centralized grease supply, and achieve The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

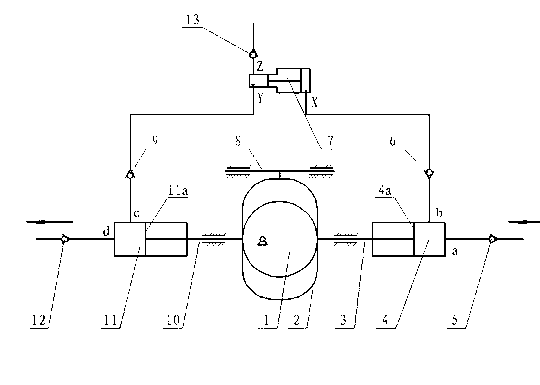

[0010] The centralized lubricating grease conveying cooperative system of the present invention is mainly composed of an eccentric wheel 1, a reciprocating frame 2, rods 3, 10, a cylinder 4, a grease cylinder 11, a booster cylinder 7, a rod, and a one-way valve. Wherein: the eccentric wheel 1 is tangent to the inner surface of the reciprocating frame 2, and the rotation of the eccentric wheel 1 drives the reciprocating frame 2 to reciprocate back and forth. The left and right sides of the reciprocating frame 2 are provided with a rod one 3 and a rod three 10, and the upper end of the reciprocating frame 2 is provided with a rod two 8, and the eccentric wheel 1 rotates to drive the reciprocating motion of the reciprocating frame 2. Rod one 3 is connected with the piston 4a of the cylinder 4, the rod three 10 on the left side of the reciprocating frame 2 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com