Denitration catalyst wear rate testing device and testing method

A technology of denitration catalyst and testing device, which is applied in measurement devices, testing wear resistance, instruments, etc., can solve problems such as uniformity of reduction methods, differences in wear degree in the vertical direction, and obstacles to adding abrasives, so as to improve test results. Comparability, ensure accurate and stable control, avoid the effect of measurement deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

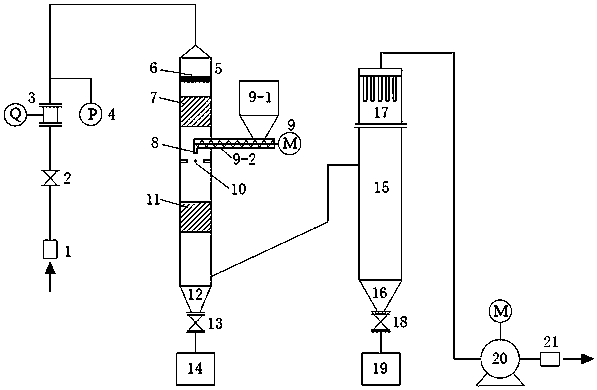

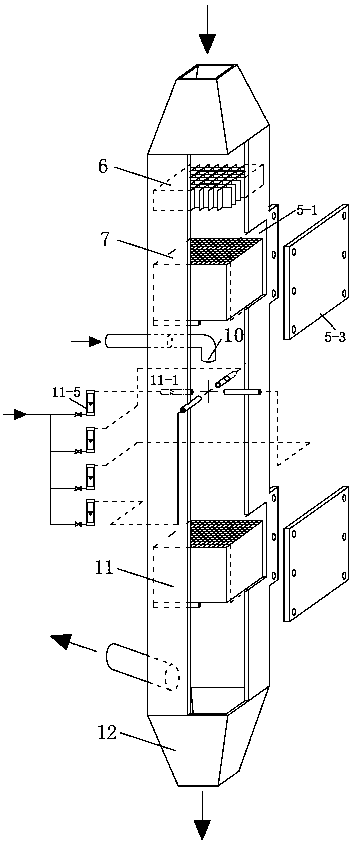

[0030] like figure 1 As shown, a denitrification catalyst wear rate test device in this embodiment includes an air inlet, a wear chamber 5, a wear agent feeder 9, a settling chamber 15, and an induced draft fan 20; The duct is connected to the air inlet, and the air inlet is provided with an air inlet filter 1, and the inlet air duct is provided with an inlet valve 2, a vortex street gas flow meter 3 and a gas pressure gauge 4; the air flows into the intake air from the air inlet filter 1 After the air duct passes through the inlet valve 2, the air flow is measured by the vortex street gas flow meter 3, and the static pressure of the air in the air duct is monitored by the gas pressure gauge 4.

[0031] A rectification grid 6, a comparison sample 7 and a test sample 11 are arranged in the wear chamber 5 in order from top to bottom. After the air enters the wear chamber 5, it first passes through the rectification grille 6 to improve the uniformity of the flow field on the flo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com