Gel powder composition as well as preparation method and application thereof

A technology of gel powder and composition, which is applied in the field of gel powder composition and its preparation, can solve problems such as skin and eye irritation, increase fun and dexterity, enhance fun and dexterity, and be good Effects of tensile and deformation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

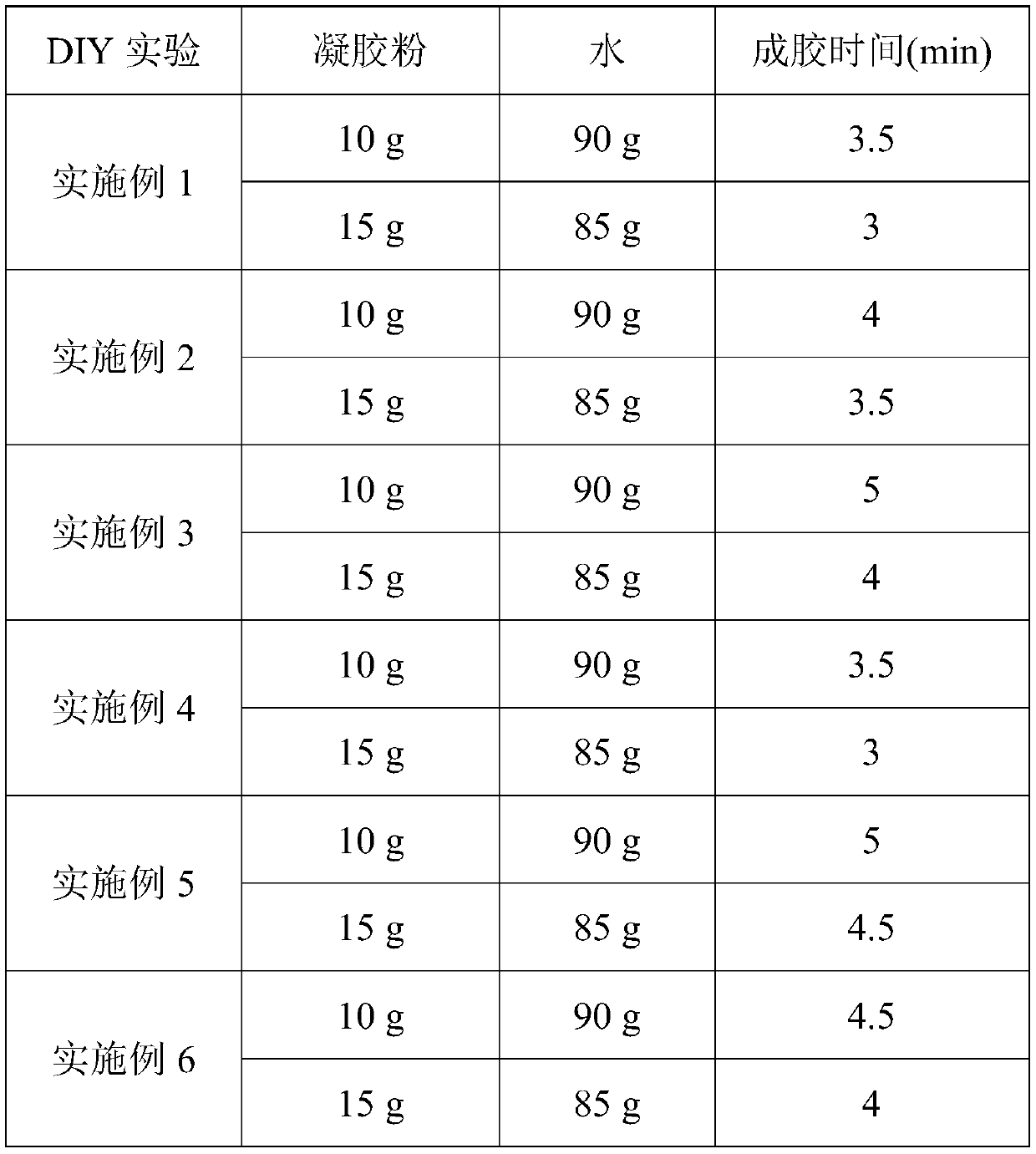

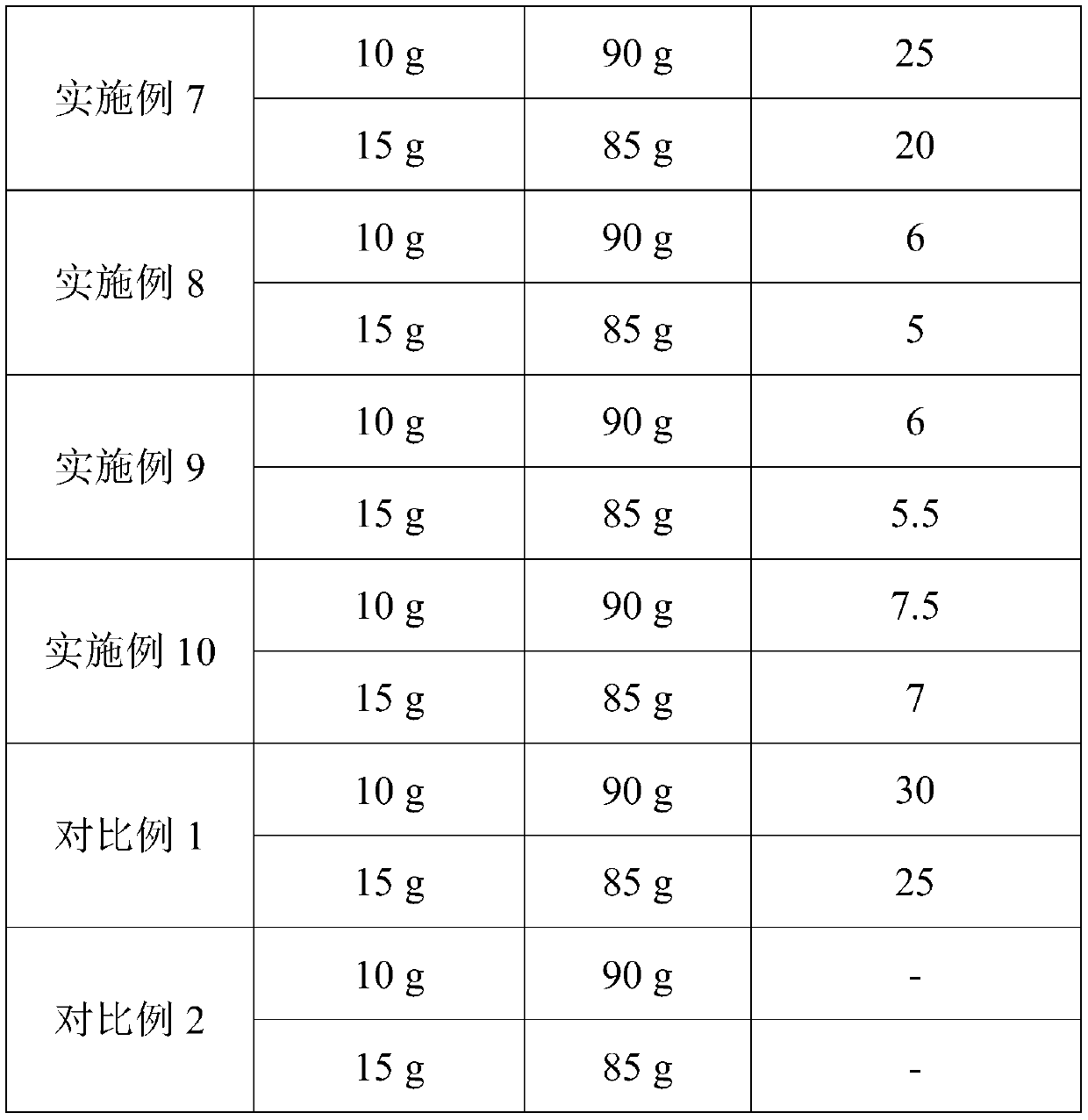

Embodiment 1

[0063] The invention provides a gel powder composition and a preparation method thereof.

[0064] Wherein, the preparation raw material of described gel powder composition comprises: 80 parts of tamarind gum, 5 parts of guar gum, 1 part of glucose, 0.1 part of borax, 0.1 part of citric acid, 1 part of potassium sorbate, 1 part of sodium chloride , 0.1 parts of agar and 11.7 parts of water.

[0065] The preparation method comprises the following steps:

[0066] Heat tamarind gum, guar gum, glucose, borax, citric acid, potassium sorbate, sodium chloride, agar and water to 70°C, mix at a stirring speed of 100rpm for 1h, dry at 100°C for 10min, and pulverize, Pass through a 120-mesh sieve to obtain the gel powder composition, wherein the gel powder composition has a fineness of 120 mesh.

Embodiment 2

[0068] The invention provides a gel powder composition and a preparation method thereof.

[0069] Wherein, the preparation raw material of described gel powder composition comprises: 60 parts of tamarind gum, 15 parts of guar gum, 3 parts of glucose, 0.01 part of borax, 0.1 part of citric acid, 1 part of potassium sorbate, 1 part of sodium chloride , 0.3 parts of agar, 0.1 part of food coloring fruit green, 0.1 part of jasmine essence and 19.39 parts of water.

[0070] The preparation method comprises the following steps:

[0071] Heat tamarind gum, guar gum, glucose, borax, citric acid, potassium sorbate, sodium chloride, agar, fruit green food coloring, jasmine essence and water to 80°C, and mix at a stirring speed of 150rpm for 0.5h. Dry at 120° C. for 8 minutes, pulverize, and pass through an 80-mesh sieve to obtain the gel powder composition, wherein the gel powder composition has a fineness of 80 mesh.

Embodiment 3

[0073] The invention provides a gel powder composition and a preparation method thereof.

[0074] Wherein, the preparation raw material of described gel powder composition comprises: 70 parts of tamarind gum, 10 parts of guar gum, 2 parts of glucose, 0.05 part of borax, 0.2 part of citric acid, 2 parts of potassium sorbate, 2 parts of sodium chloride , 0.5 parts of agar and 13.25 parts of water.

[0075] The preparation method comprises the following steps:

[0076] Heat tamarind gum, guar gum, glucose, borax, citric acid, potassium sorbate, sodium chloride, agar, and water to 60 ° C, mix at a stirring speed of 200 rpm for 1 h, dry at 90 ° C for 12 min, and pulverize , through a 100-mesh sieve to obtain the gel powder composition, wherein the fineness of the gel powder composition is 100 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com