Flux-cored wire for gas shield welding of high-strength steel

A technology of welding wire and steel gas, applied in the direction of welding/welding/cutting items, welding medium, welding equipment, etc., to achieve the effect of taking into account the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

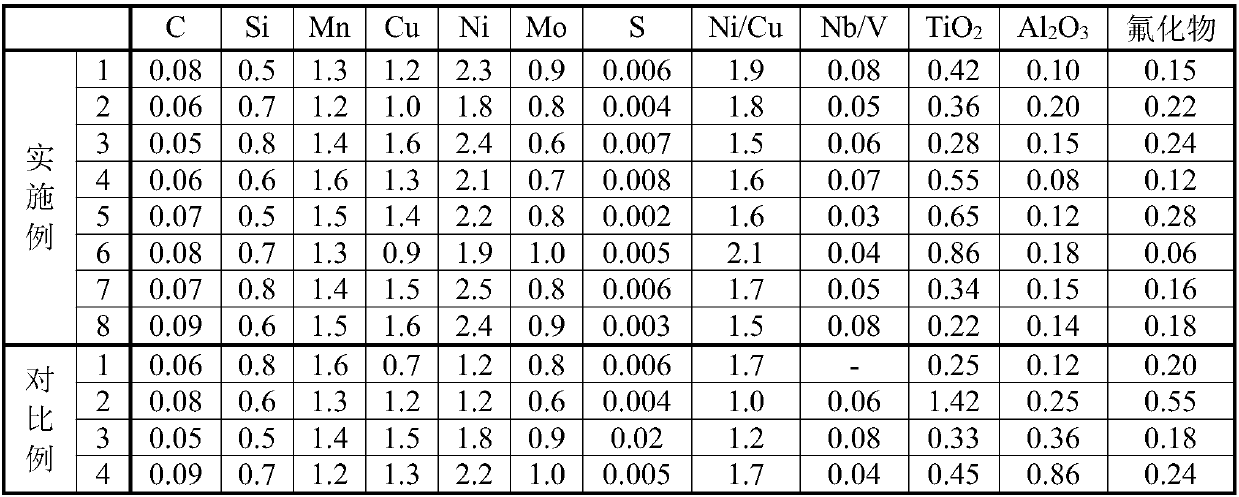

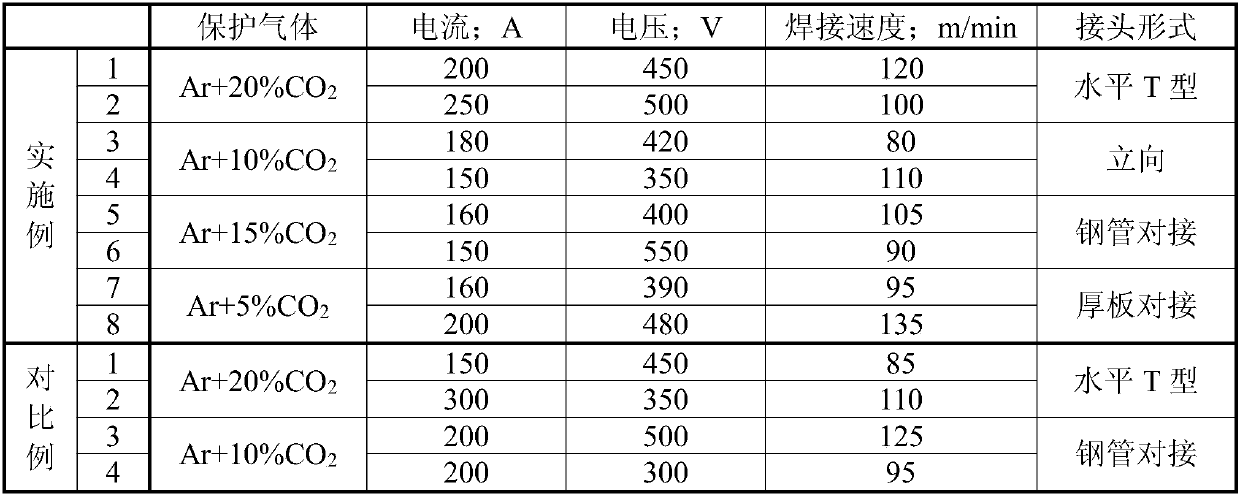

[0037] The welding test is carried out on the T-joint of 8mm thick HT780 steel plate, in the horizontal position.

[0038] The diameter of the welding wire is 1.2 mm, the chemical composition is shown in Table 1, and other welding parameters are shown in Table 2.

[0039] The welding test results are shown in Table 3.

Embodiment 3-4

[0041] The steel plate is Q890 with a thickness of 16mm, and is welded vertically. The groove is single-sided V-shaped 35°.

[0042] The diameter of the welding wire is 1.2 mm, the chemical composition is shown in Table 1, and other welding parameters are shown in Table 2.

[0043] The welding test results are shown in Table 3.

Embodiment 5-6

[0045] The HT780 steel pipe with an outer diameter of 800mm and a wall thickness of 12mm is selected for circumferential butt welding, and the groove is a single-sided V-shaped 30°.

[0046] The diameter of the welding wire is 1.2 mm, the chemical composition is shown in Table 1, and other welding parameters are shown in Table 2.

[0047] The welding test results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com