Emulsified asphalt mixture and preparing method thereof

A technology of emulsified asphalt and mixture, which is applied in the field of emulsified asphalt to achieve the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

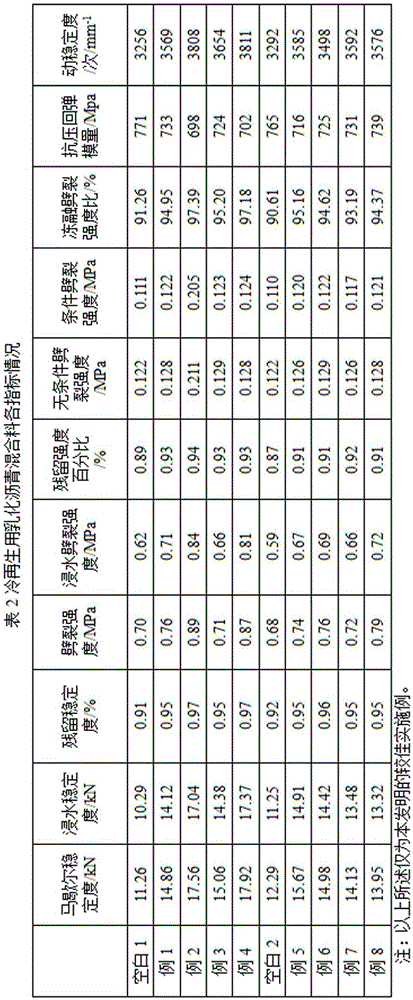

Embodiment 1

[0019] The emulsifier used in Example 1 is the lignin amine emulsifier KLQAS. Weigh 90 parts of stone according to the gradation, add 2% sulphoaluminate fast hardening cement, add 0.2% polyvinyl alcohol fiber and 0.2% mortar king, add 12% tap water, stir the aggregate evenly, add 8% emulsified asphalt, Stir quickly evenly, and prepare the corresponding test specimens.

Embodiment 2

[0020] The emulsifier used in Example 2 is the lignin amine emulsifier KL-F-DETA. Weigh the stones according to the gradation, add 4% sulphoaluminate fast hardening cement, 0.3% polyvinyl alcohol fiber and 0.3% mortar, add 10% tap water, and mix the aggregate evenly. , Add 6% emulsified asphalt in the total mixture, mix quickly and evenly, and prepare corresponding test specimens.

Embodiment 3

[0021] The emulsifier used in Example 3 is the lignin amine emulsifier KLQAS. Weigh the stones according to the gradation, add 2% of the total mixture of ordinary Portland cement number 425, add 1% of the cement mass of sodium sulfate, add 0.2% and 0.2% of the mixture of polyvinyl alcohol fiber and Mortar King, add 11% tap water, mix the aggregate evenly, add 4% emulsified asphalt, which accounts for the total amount of the mixture, mix quickly evenly, and prepare the corresponding test specimens.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com