Motion guide device and method of producing the same

A technology of motion guidance and rolling elements, applied in the direction of linear motion bearings, bearings, shafts and bearings, can solve the problems that cannot be said to have sufficient strength and cannot fully realize light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

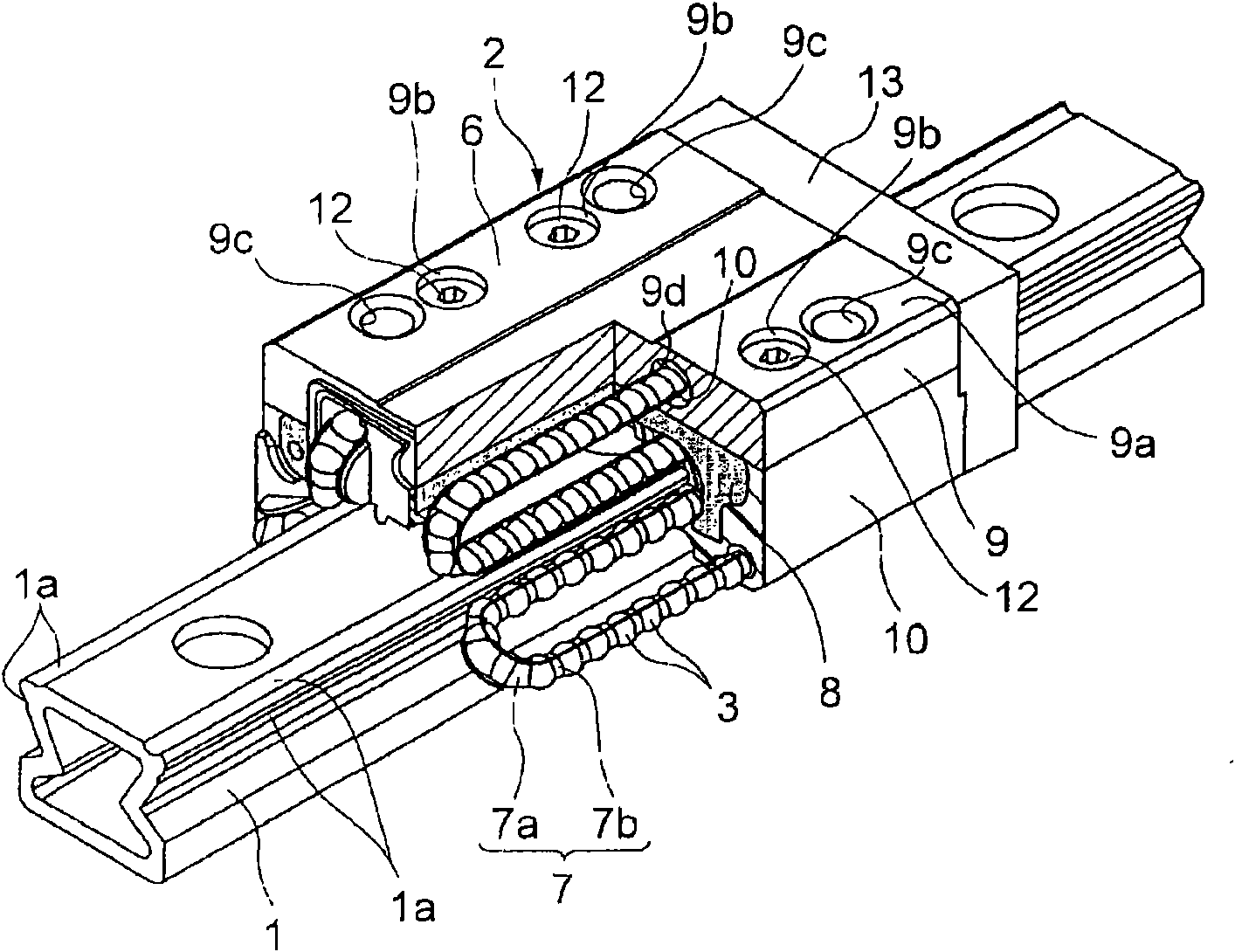

[0116] figure 1 It is a perspective view showing the motion guidance device in the first embodiment of the present invention. This motion guide has a rail 1 as a rail member and a moving block 2 that slides along the rail 1 . The rail 1 is mounted on the base, and the moving block 2 is mounted on a target part to be guided. Balls 3 as rolling elements are interposed between the rail 1 and the moving block 2 in a rolling manner.

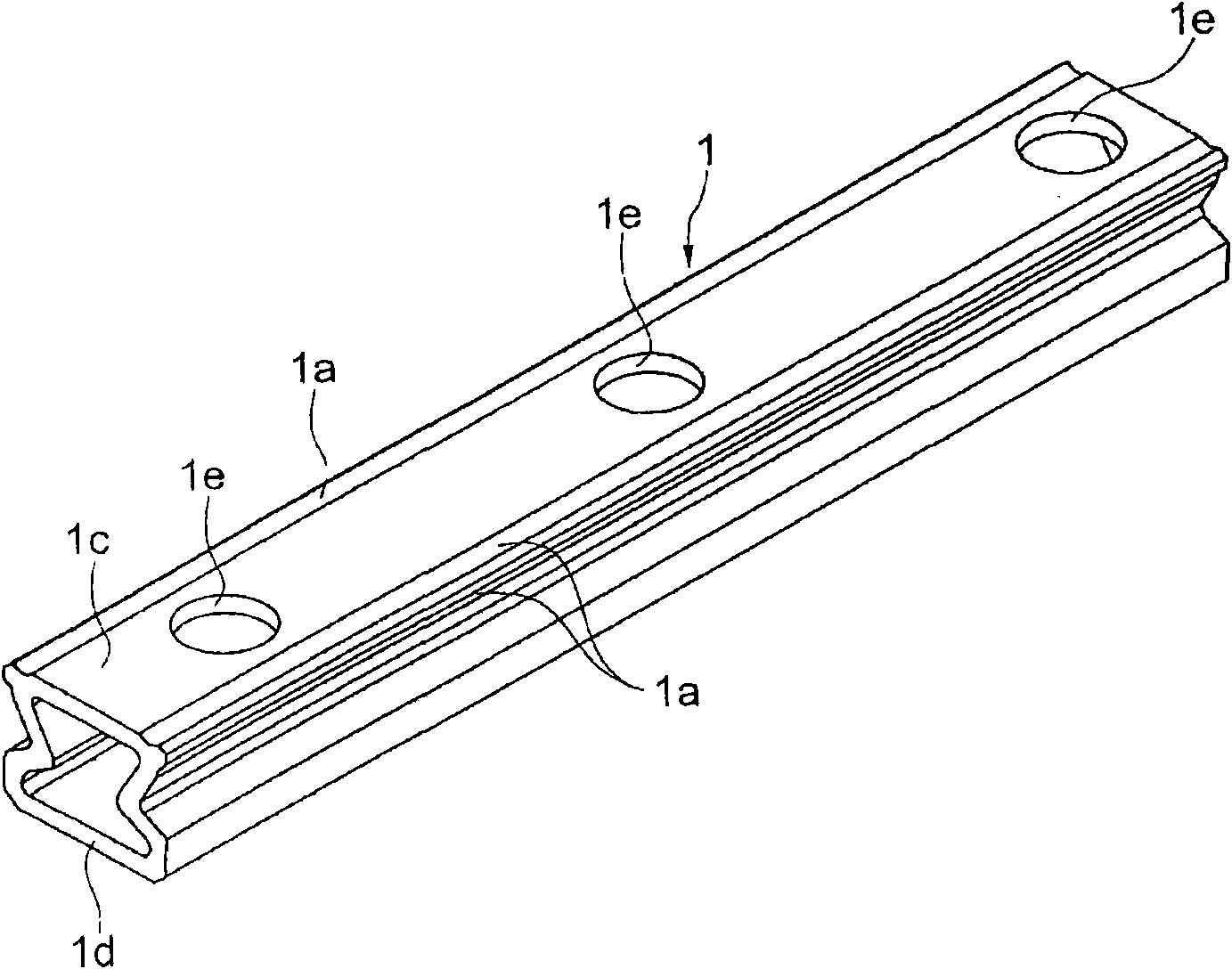

[0117] figure 2 Indicates the hollow track 1. The rail 1 has a special-shaped cross section and extends in an elongated straight line. On the left and right ends of the upper surface of the rail 1, for example, two ball track grooves 1a extending in the longitudinal direction are formed as rolling element track portions. On the upper end portions of the left and right side surfaces of the rail 1, for example, two ball rolling grooves 1a extending in the longitudinal direction are processed as rolling element track portions. That is, in this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com