Fan impeller

A fan impeller and wheel hub technology, which is applied in the field of industrial ventilation, can solve problems such as easy changes in positional relationship, difficulty in meeting use requirements, deformation, etc., and achieve the effect of enhancing strength and taking into account strength and ventilation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

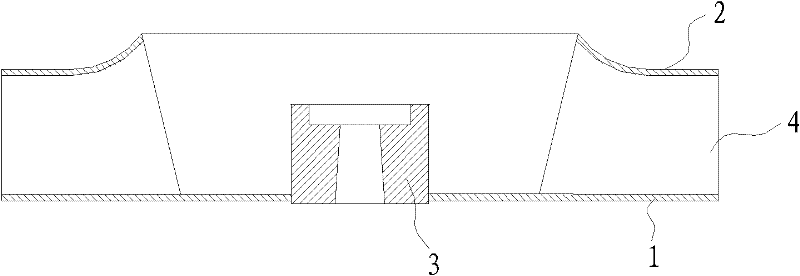

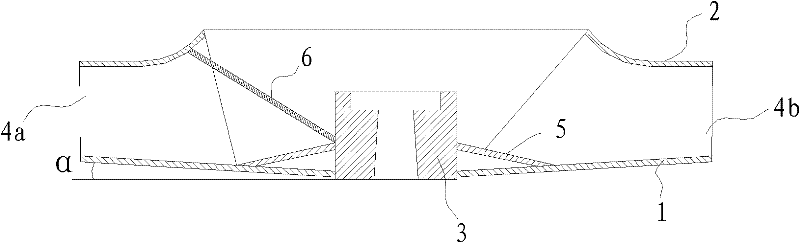

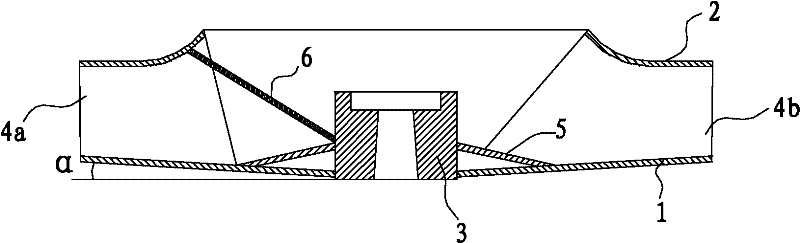

[0013] see figure 2 The fan impeller of the present invention includes a hub 3, the hub 3 has an axial through hole for penetrating the drive shaft, the bottom periphery of the hub 3 is provided with an annular rear disc 1, the bottom edge of the blade is fixed on the upper surface of the rear disc 1, and the top of the blade All along the bottom surface that is fixed on the ring-shaped front plate 2.

[0014] The descriptions about orientation in the present invention, such as up, down, top, and bottom, are relative to the drawings, and do not represent absolute orientations.

[0015] Between the outer wall of the hub 3 and the upper surface of the rear disc 1, a cone-shaped reinforcing cone 5 is arranged, the inner edge of the middle hole of the reinforcing cone 5 is connected with the outer wall of the hub 3, and the bottom edge of the reinforcing cone 5 is connected with the upper surface of the rear disc 1 .

[0016] The annular rear disc 1 has a middle hole, and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com