Anti-clamping cross-seam comb-tooth type bridge expansion device

A telescopic device, comb type technology, used in bridges, bridge construction, bridge parts and other directions, can solve the problems of easy dust accumulation, easy damage, stuck stone, etc. The effect of the stone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

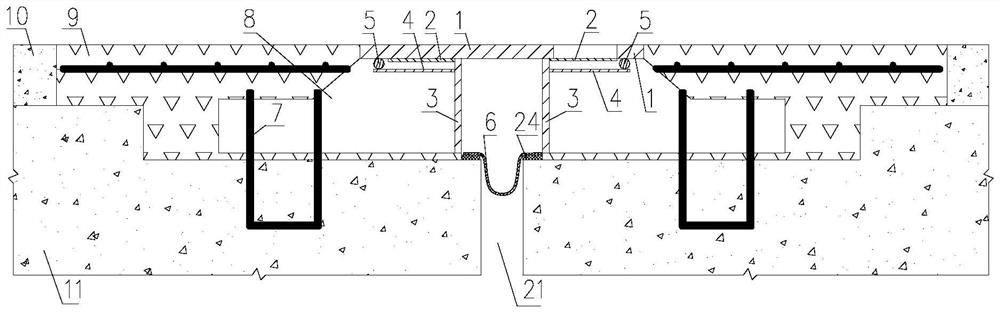

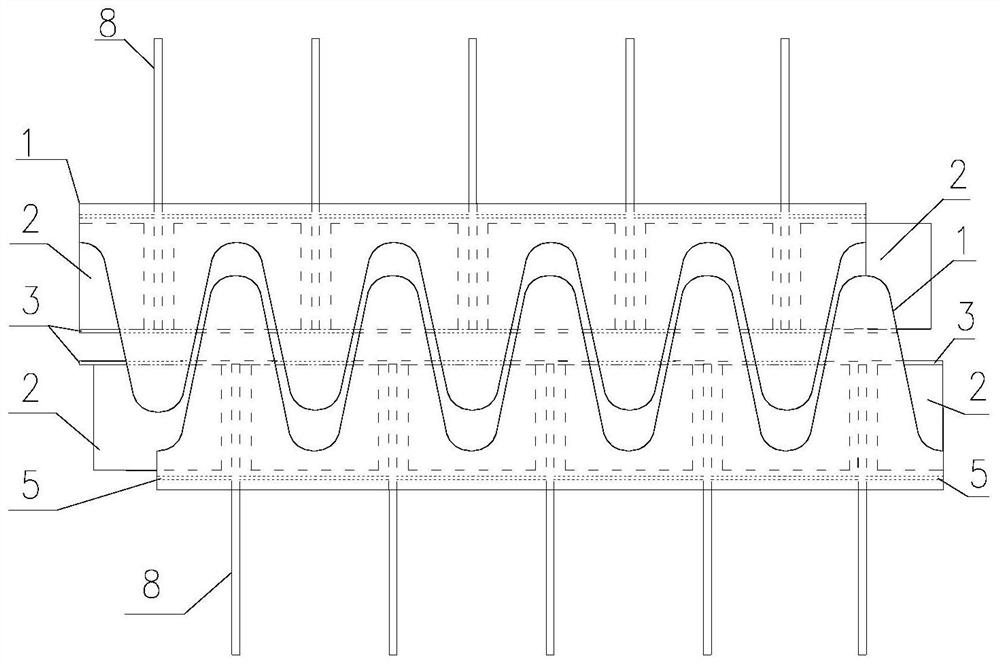

[0033] Embodiment one, such as figure 1 , 2 The small cantilever butt joint expansion device, the expansion of the beam gap is less than or equal to 240mm, and the structures on both sides of the beam gap are symmetrically arranged, such as figure 2 The comb teeth in the embodiment are curved plates protruding longitudinally, and the overall shape is relatively small. The comb teeth are horizontally arranged in the shape of a plate, and the comb teeth can also be in the shape of rectangular strips, and a pair of opposite comb teeth are arranged alternately. figure 1 The top of the anchor plate 8 in the embodiment is directly welded to the bottom surface of the comb-tooth member 1. In order to enhance the smoothness of the road surface as much as possible, the shutter 2 is welded close to the bottom of the comb-tooth member 1, and the front end of the shutter 2 is welded to the side beam 3. Both sides reach the anchor plate 8 at the longest, and the rear part covers the alveo...

Embodiment 2

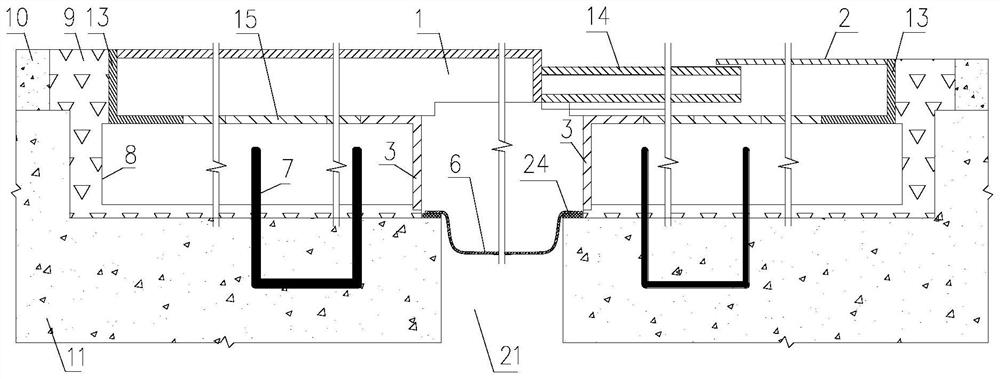

[0035] Embodiment two, such as image 3 , 4 Medium and large cantilever butt-joint expansion devices, the expansion of the beam gap is more than 320mm, and the structures on both sides of the beam gap are arranged symmetrically, which requires higher load-bearing and impact resistance performance. The thickness of the comb piece 1 is required to increase. In the embodiment, a special steel plate is used to cut a special shape, and a baffle plate 13 made of angle steel is used at the end to prevent cement from entering the gap on both sides of the comb piece. The comb tooth of the comb tooth piece 1 is a special shaped strip made of steel plate. In order to seal the hole in front of the tooth end, an extension tooth 14 is welded at the front end of the comb tooth piece 1, which has sufficient compression resistance and elasticity. Shield plate 2 is welded in the front slot of extension tooth 14, shield plate 2 is welded with the baffle plate 13 on the opposite side as a part o...

Embodiment 3

[0036] Embodiment three, such as Figure 5 , 6 The medium is a small joint-span supporting expansion device, the expansion of the beam joint is less than or equal to 240mm, and the structures on both sides of the beam joint are asymmetrically arranged. The comb piece is a horizontally arranged comb plate, the top of the anchor plate 8 on the opposite side is welded to the horizontal backing plate 15, the front end is welded to the side beam 3, and a baffle plate 13 is welded to the tail below the comb plate to prevent the rear Pour cement into it. A rubber support 17 is placed between the top of the anchor plate 8 and the comb plate 1 , and the post-cast concrete is flush with the top of the anchor plate 8 , and the rubber support 17 is laid on the concrete. A row of stepped stud holes is arranged horizontally behind the side beam 3 of the comb on one side. The stud holes are set on one side of the anchor plate 8. The studs 22 pass through the stud holes. The lower part is w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com