Building structure formed by connecting prefabricated wall boards through dense ribs and constructing method of building structure

A technology for prefabricating wall panels and building structures, which is applied in building components, building structures, buildings, etc., can solve the problems of shortening, the need to strengthen the overall stability, and prolonging the cycle time of the wall panel forming turnaround time, so as to achieve both overall strength, The effect of taking into account the construction operability and the simple and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

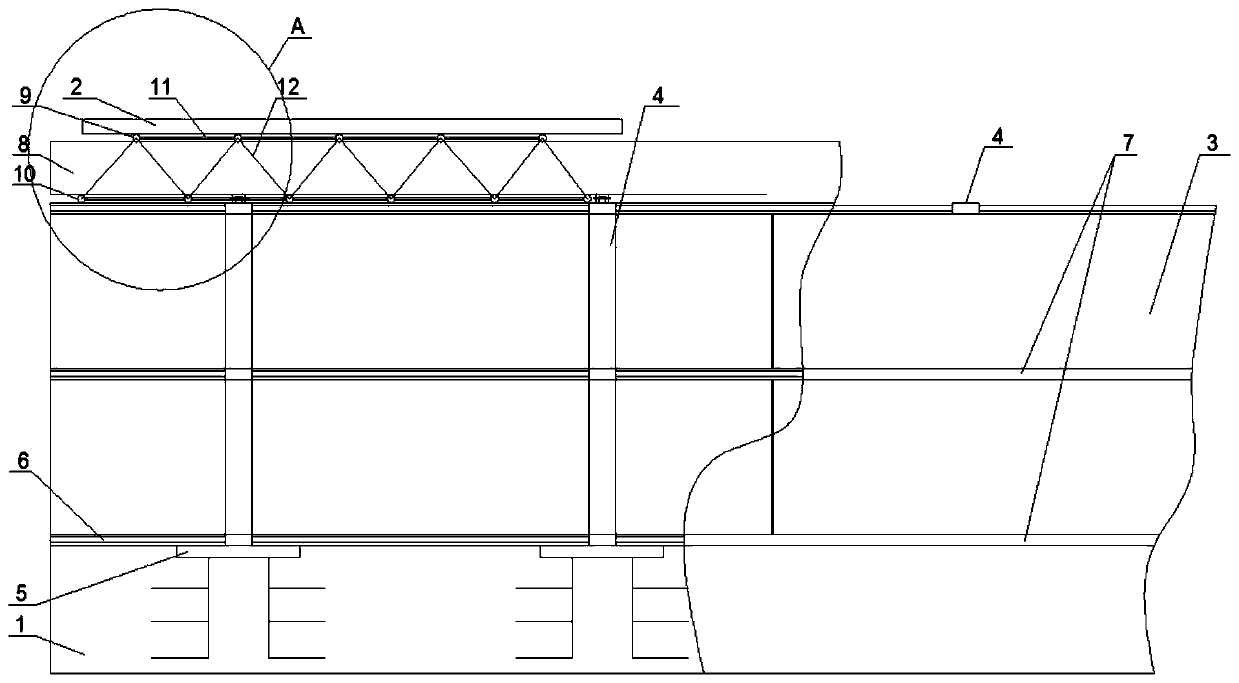

[0032] Example 1, such as figure 1 As shown, based on the consideration of high support strength, the crossbeam 8 is a reinforced concrete prefabricated structure, and the spanning support structure includes an upper spanning tube 9 and a lower spanning tube 10 respectively distributed on the upper and lower end faces of the crossbeam 8. Transverse connecting rods 11 are arranged between the spanning tubes 9 and between the lower spanning tubes 10, and the upper spanning tubes 9 and the lower spanning tubes 10 are connected and fixed in a staggered form by means of fixed rods 12, thus forming a truss structure, supporting The best strength;

[0033] As mentioned above, the construction method based on steel pipe prefabricated lightweight wallboard building structure includes the following steps:

[0034] A. Prefabricated prefabricated lightweight wall panels

[0035] Such as Figure 5 As shown, install an n-shaped base 18 attached to its inner wall in the molding cavity, an...

Embodiment 2

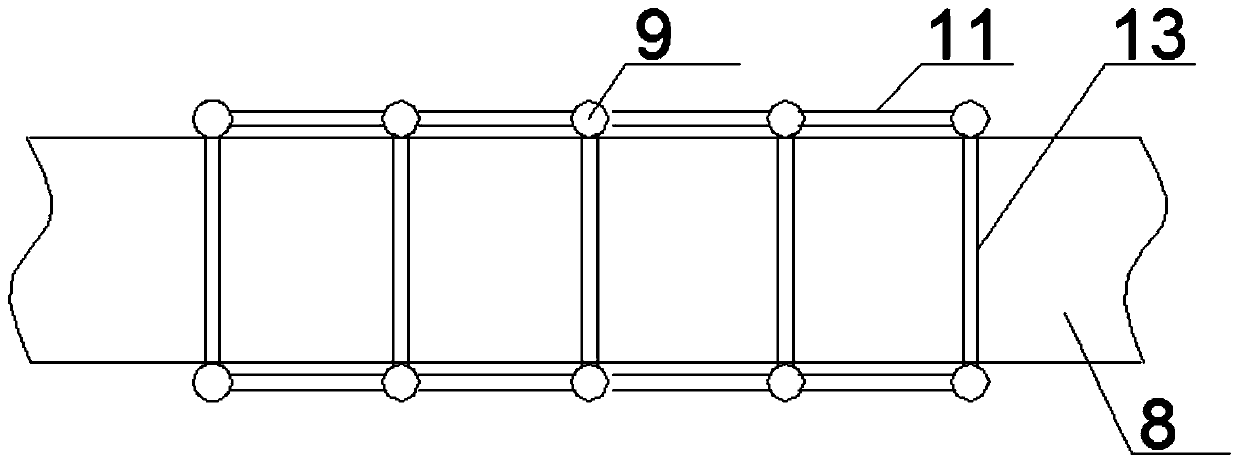

[0044] Example 2, such as figure 2 As shown, based on the consideration of medium support strength requirements, the spanning support structure includes upper spanning tubes 9 and lower spanning tubes 10 respectively distributed on the upper and lower end faces of the beam 8, between the upper spanning tubes 9 and the lower spanning A horizontal connecting rod 11 is arranged between the tubes 10, and the upper and lower spanning tubes 9 and 10 are arranged facing each other up and down. connecting rod 13;

Embodiment 3

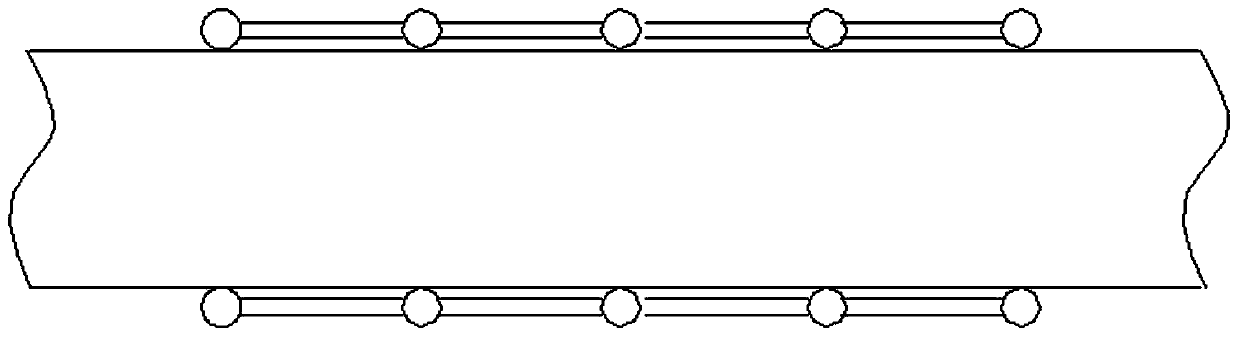

[0045] Example 3, such as image 3 As shown, based on the consideration of lower support strength requirements, the spanning support structure includes upper spanning tubes 9 and lower spanning tubes 10 respectively distributed on the upper and lower end surfaces of the beam 8, between the upper spanning tubes 9 and the lower spanning tubes A horizontal connecting rod 11 is arranged between the spanning pipes 10, and there is no connection between the upper spanning pipe 9 and the lower spanning pipe 10;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com