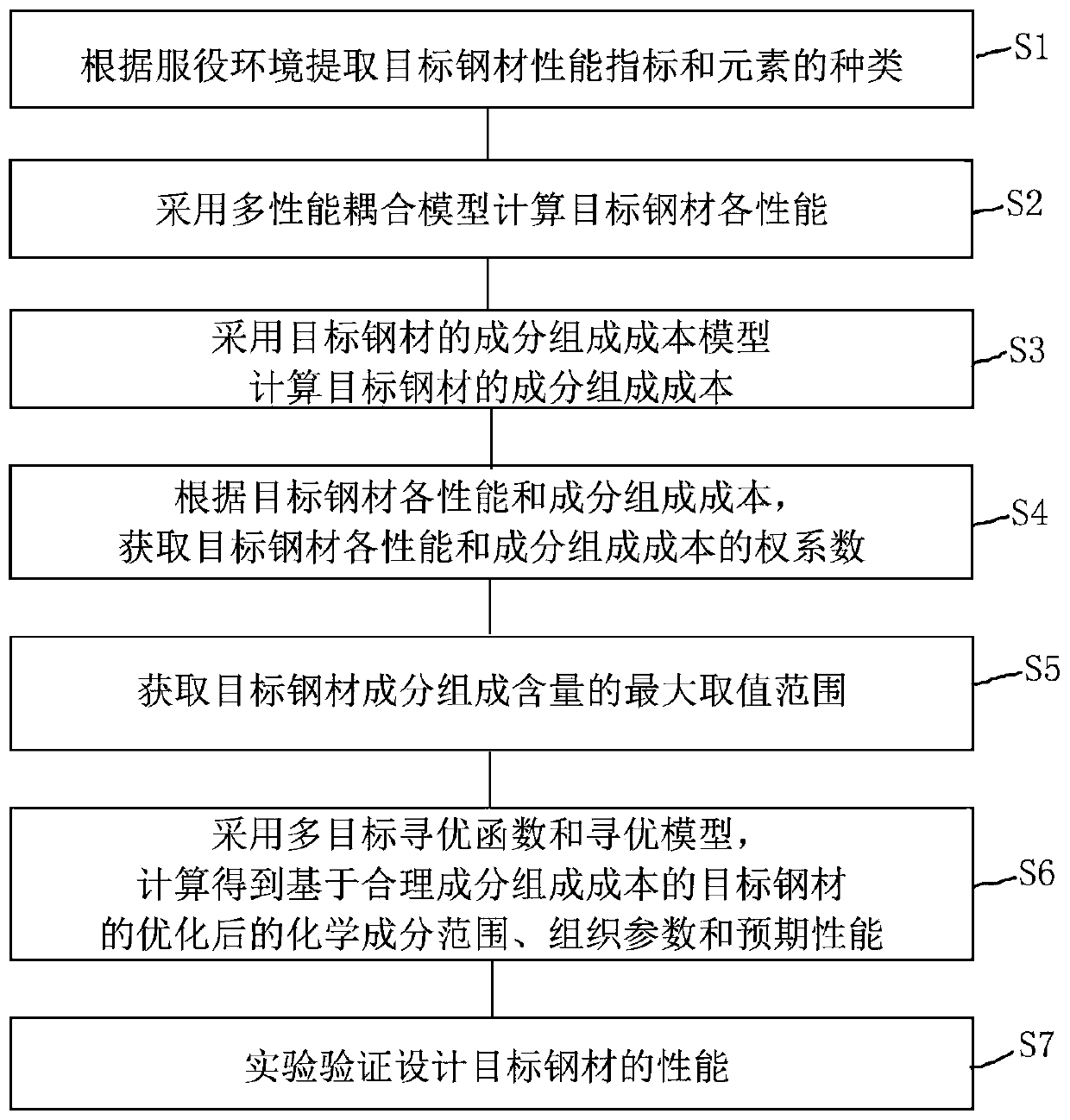

Multi-performance-coupled optimized steel optimization method

An optimization method and steel technology, applied in computer materials science, informatics, instruments, etc., can solve problems such as limiting the use range of materials, achieve the effect of reducing material design cycle, reducing composition cost, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0117] Embodiment: Design a kind of steel material that is easy to weld, has high corrosion resistance and yield strength above 390MPa, and has impact toughness above 60J at -40°C. The material can resist atmospheric corrosion, single medium or mixed medium corrosion of chloride ion and sulfite ion. The designed steel needs to achieve the coupling of weldability, corrosion resistance, strength and toughness.

[0118] (1) Extract target steel performance indicators and element types according to the service environment:

[0119] Table 1 Performance and cost target values of design steel grades

[0120]

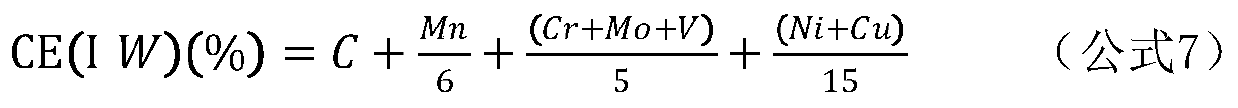

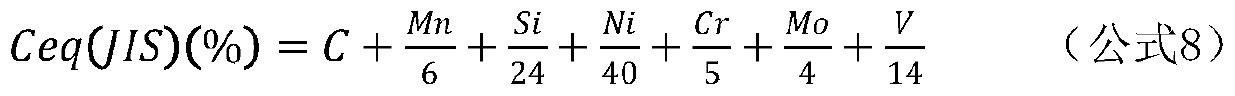

[0121] (2) The range of chemical elements determined according to the above-mentioned objectives. Compositional elements include: commonly used compositional elements C, Si, Mn, S, P, compositional elements Ni, Cr, Cu for improving atmospheric corrosion resistance, micro-component composition for grain refinement, precipitation strengthening and improvement of corrosion r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com