Reinforcing and toughening masterbatch for vinyl polymer and preparation method thereof

A vinyl polymer, strengthening and toughening technology, applied in the field of chemical materials, can solve the problems of inability to take into account the toughness and the impact resistance of materials, and achieve the effect of improving the dispersion effect, reducing the cost of raw materials, and high dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Reinforcing and toughening masterbatch for vinyl polymers, including the following components and weight fraction ratios:

[0023] Nano silica: 20-50%,

[0024] Ultrafine calcium carbonate: 5-20%, the average particle size of the electron microscope is 50-100nm,

[0025] Ethylene-acrylate-carbon monoxide: 10-30%,

[0026] EVA resin (ethylene-vinyl acetate copolymer): 5-20%,

[0027] Dispersant: 1.1%-5%.

[0028] Wherein, the dispersant adopts the mixture of polyethylene wax, stearic acid and paraffin.

Embodiment 2

[0030] This embodiment is optimized on the basis of the weight fraction of the components in Example 1, including the following components and weight fraction ratio:

[0031] Nano silica: 30-40%,

[0032] Ultrafine calcium carbonate: 5-15%,

[0033] Ethylene-acrylate-carbon monoxide: 25-35%,

[0034] EVA resin (ethylene-vinyl acetate copolymer): 5-15%,

[0035] Polyethylene wax: 0.5%-1.5%,

[0036] Stearic acid: 0.3%-1.5%,

[0037] Paraffin: 0.3%-2%.

[0038] Example 1 and Example 2 use the multi-component graft copolymer type toughening agent ethylene-acrylate-carbon monoxide, which has a low melting point, high reactivity, high dispersibility and toughness itself, and can effectively improve the relationship between nano inorganic particles and polymers. The interfacial properties between them are easy to disperse, giving full play to the strengthening and toughening effect of nano-inorganic molecules, and the synergistic toughening of the toughening agent and the coati...

Embodiment 3

[0040] Reinforcing and toughening masterbatch for vinyl polymers, including the following components and weight fraction ratios:

[0041] Nano silica: 20-50%, preferably 30-40%,

[0042] Ultrafine calcium carbonate: 5-20%, the electron microscope average particle diameter of ultrafine calcium carbonate is 50-100nm, preferred, 5-15%,

[0043] Ethylene-acrylate-carbon monoxide: 10-35%, preferably, 25-35%,

[0044] EVA resin (ethylene-vinyl acetate copolymer): 5-20%, preferably, 5-15%,

[0045] Dispersant: 1.1%-5%, preferably, 1.5%-5%,

[0046] Coupling agent: less than 3%.

[0047] In this example, on the basis of examples 1 and 2, by adding a small amount of coupling agent, the compatibility of inorganic substances and organic polymers can be improved, the interfacial bonding force can be improved, and the performance of the material can be improved.

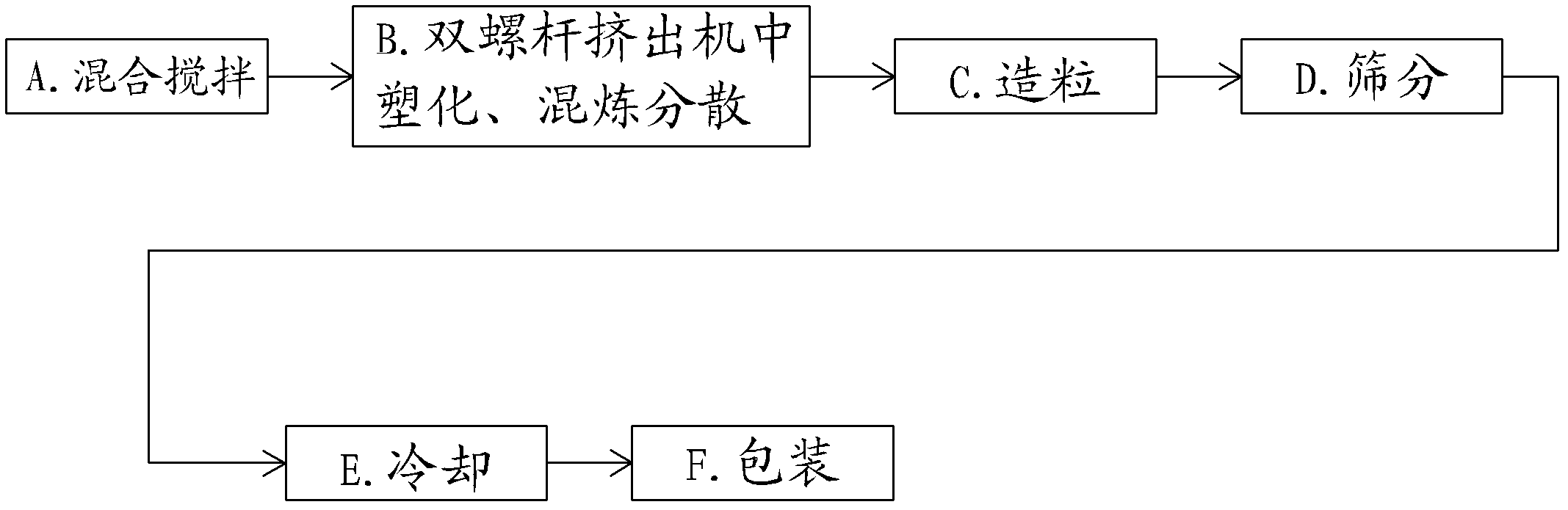

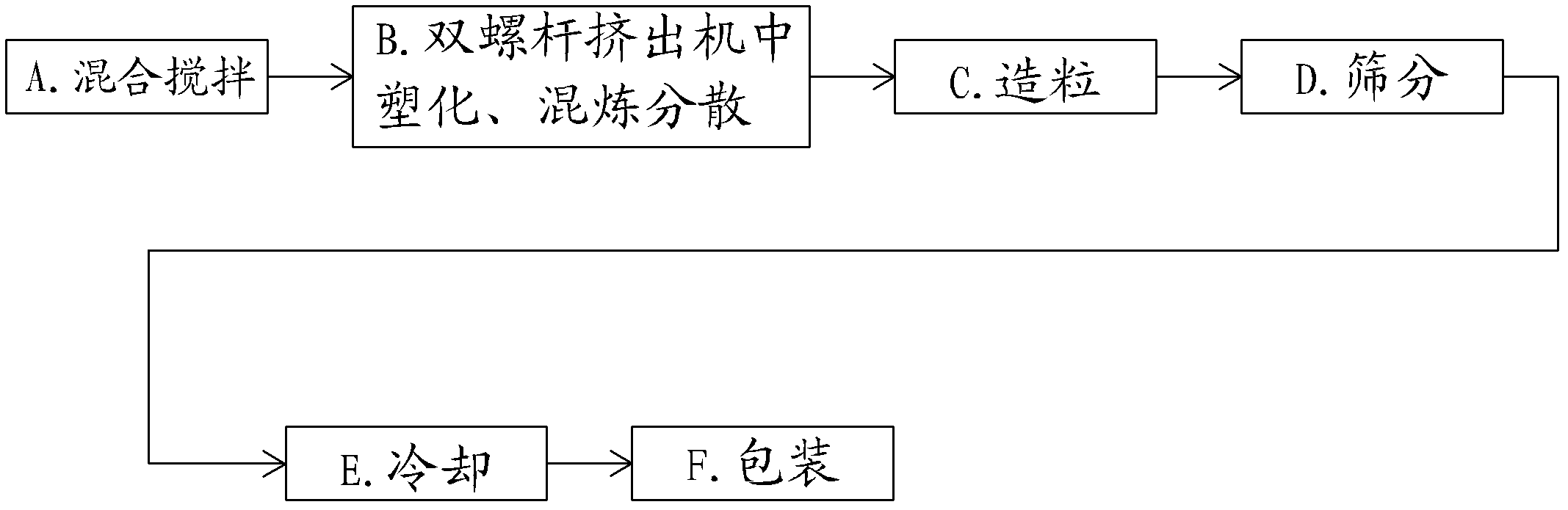

[0048] refer to figure 1 As shown, the method for preparing the above-mentioned reinforced and toughened masterbatch for v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com