A kind of silicon nitride nanofiber reinforced boron nitride ceramics and preparation method thereof

A nanofiber and silicon nitride technology, which is applied in the field of special functional ceramics, can solve the problems of complex deposition system of boron nitride ceramic matrix and adverse effects of wave transmission performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

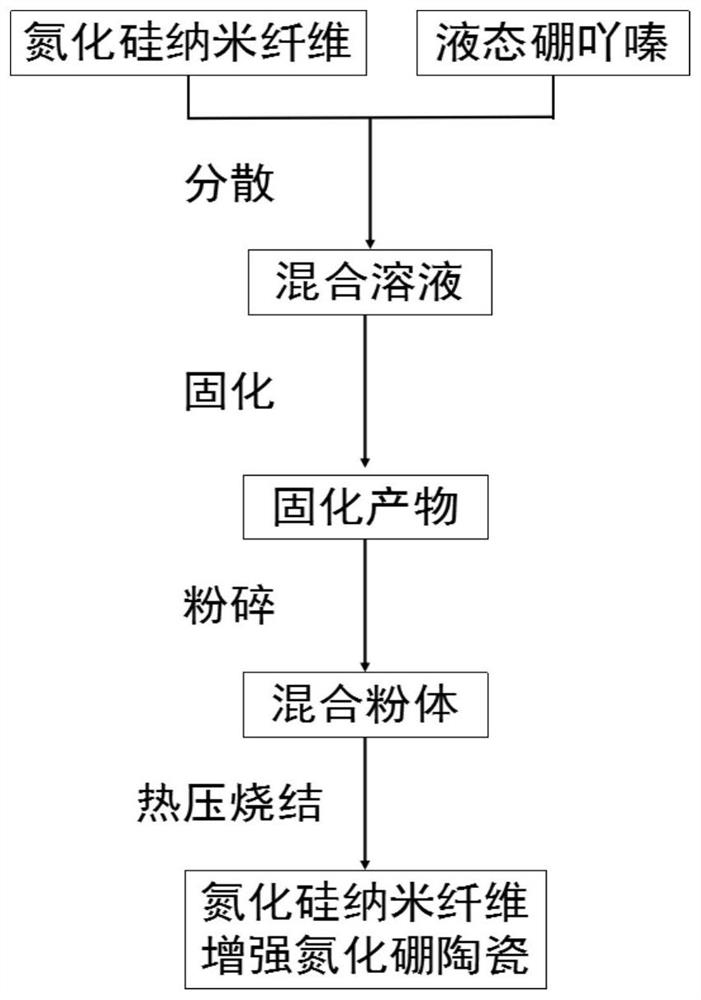

[0034] The invention also provides a preparation method of silicon nitride nanofiber reinforced boron nitride wave-transparent ceramics, figure 1 It is a process flow diagram of the inventive method, comprising the following steps:

[0035] Step 1. Dispersion of silicon nitride nanofibers in liquid borazine, heating up to 150-250°C, under a protective atmosphere with oxygen content and water content <1ppm, silicon nitride with a mass percentage of 1-6wt.% The nanofibers are added to the liquid borazine, and the nanofibers are dispersed by magnetic stirring to obtain a mixed solution; the magnetic stirring speed is 300-400 rpm, that is, 300-400 revolutions per minute.

[0036] Step 2. Solidification of the mixed solution: transfer the mixed solution to an autoclave, fill it with 5-8MPa nitrogen as a protective gas, heat the mixed solution to 150-250°C at a heating rate of 5-10°C / min and keep it warm for 3- For 5 hours, the solution was solidified to obtain a solidified produc...

Embodiment 1

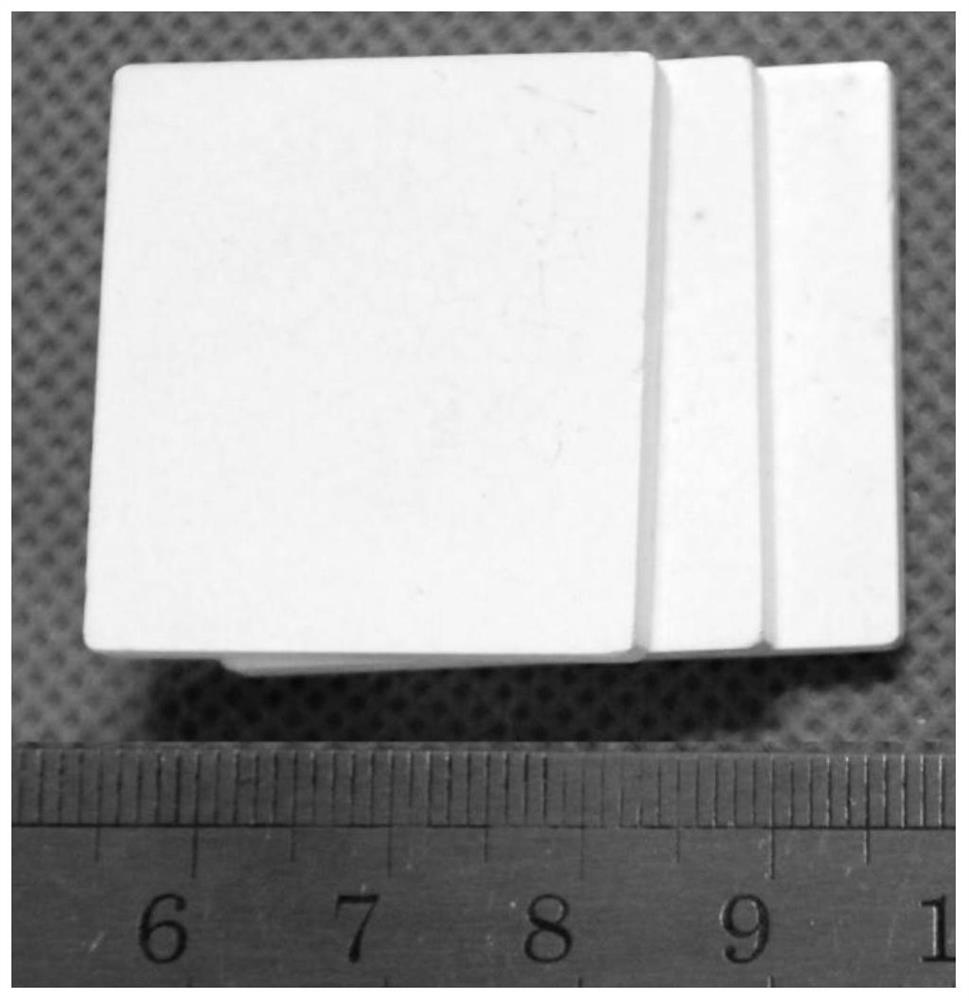

[0041] figure 2 It is the macroscopic topography diagram of the bulk ceramics prepared by the method of the present invention. refer to figure 1 In the glove box, adjust and keep the oxygen content and water content in the atmosphere < 1ppm, the silicon nitride nanofibers with a mass percentage of 1.2wt.% are gradually added to the liquid borazine, and stirred by magnetic force Disperse the nanowires, the magnetic stirring speed is 300rpm, and the stirring time is 4h to obtain a mixed solution;

[0042] (2) Transfer the mixed solution to an autoclave, fill it with 5MPa nitrogen as a protective gas, and while maintaining the magnetic stirring speed at 300rpm, heat the mixed solution to 200°C at a heating rate of 5°C / min and keep it warm for 3h, so that The mixed solution solidified;

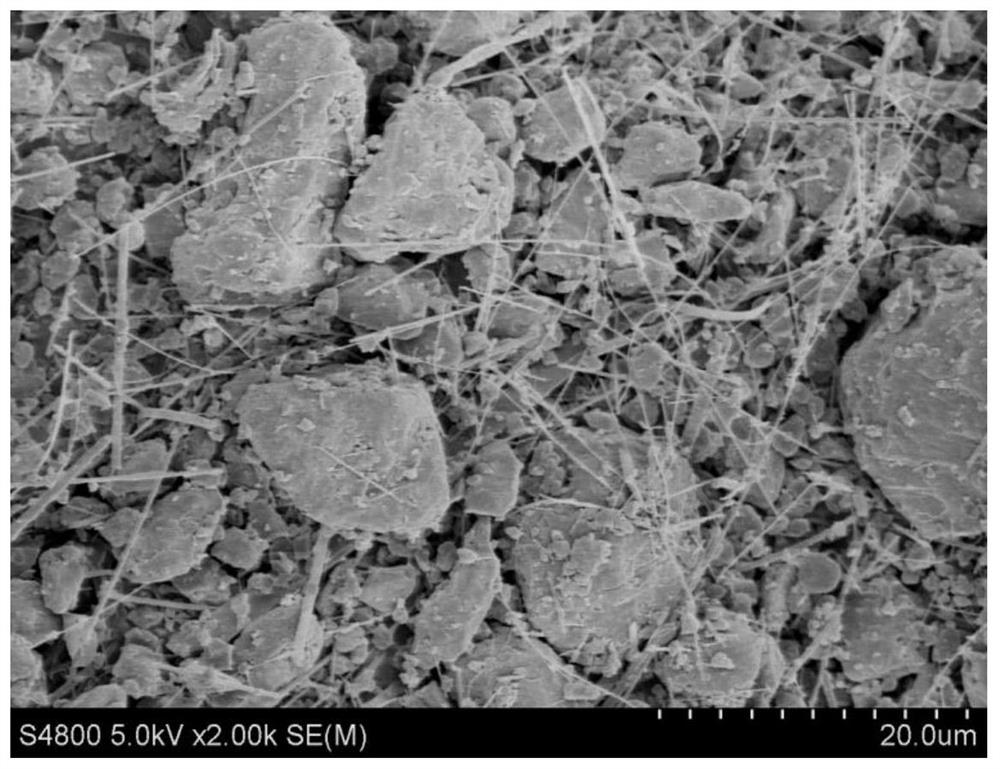

[0043] (3) The cured product of the mixed solution is pulverized by a pulverizer to obtain a mixed powder of the nanofiber and borazine cured product, and the microscopic appearance of the mix...

Embodiment 2

[0047] (1) In the glove box, keep the oxygen content and water content in the atmosphere <1ppm, gradually add silicon nitride nanofibers with a mass percentage of 5.5wt.% to liquid borazine, and stir the nanowires by magnetic force Disperse, the magnetic stirring speed is 300rpm, and the stirring time is 4h to obtain a mixed solution;

[0048] (2) Transfer the mixed solution to an autoclave, fill it with 8MPa nitrogen as a protective gas, and while maintaining the magnetic stirring speed at 400rpm, heat the mixed solution to 250°C at a heating rate of 10°C / min and keep it warm for 5h, so that The solution solidifies;

[0049] (3) Grinding the cured product of the mixed solution with a pulverizer to obtain a mixed powder of the nanofiber and borazine cured product;

[0050] (4) Place the mixed powder obtained in step (3) in a hot-press sintering furnace, apply a hot-press pressure of 15 MPa under the condition of nitrogen protection, and raise the temperature to 1600°C at a he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com