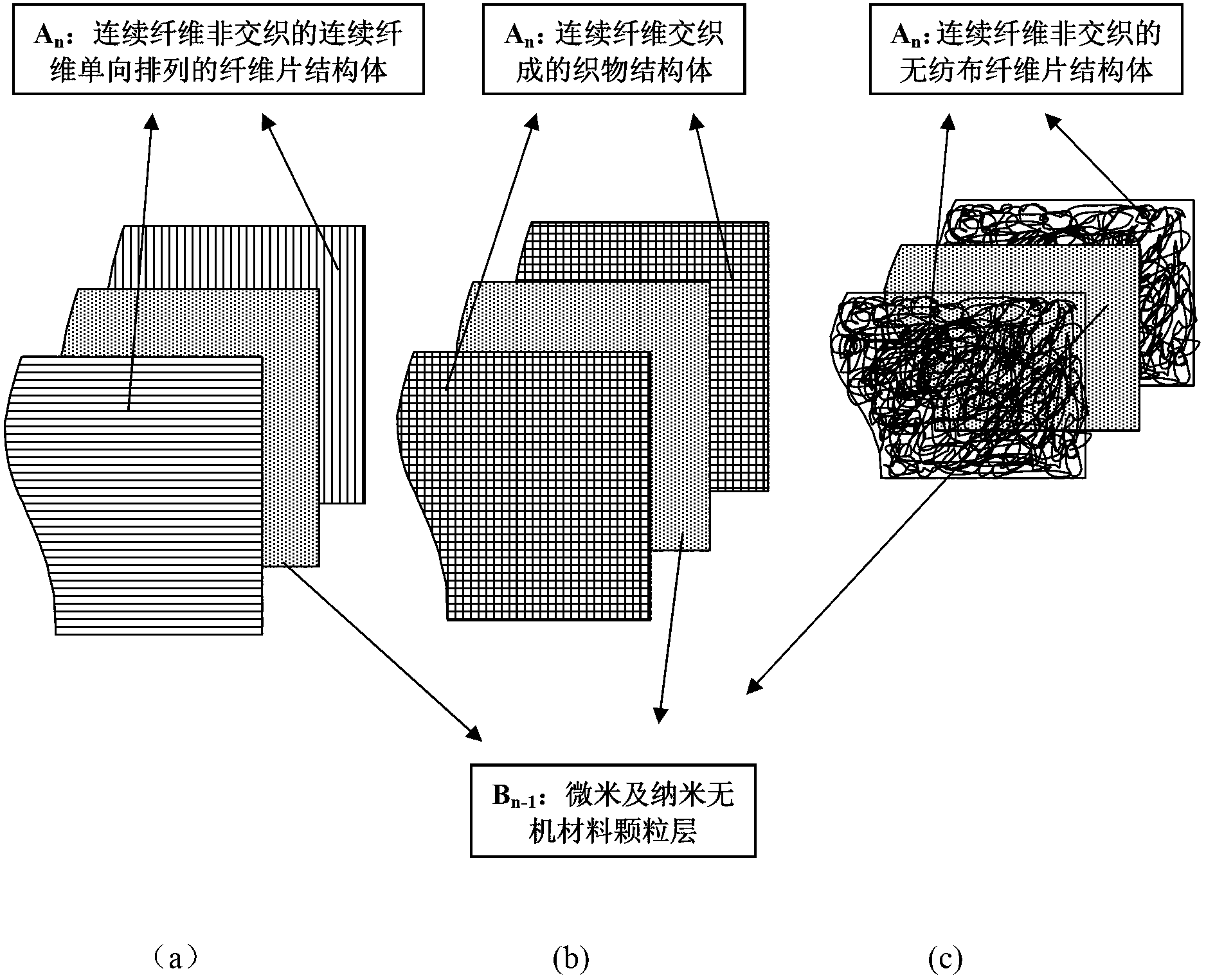

Micron and nano material-enhancing bionic layered composite material and manufacturing method thereof

A composite material and nanomaterial technology, applied in the field of biomimetic layered composite high impact resistance materials and their preparation, can solve problems such as complex microenvironment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] (1) Immerse the continuous polyester fiber in the melt of polypropylene resin (the weight average molecular weight of the polypropylene resin is about 200,000, and the molecular weight distribution is about 7.8), take it out, cool and solidify at room temperature, and obtain a polypropylene resin coating on the surface The polyester fiber is prepared into a polyester fabric structure coated with a polypropylene resin layer through a weaving method to obtain a toughened structural material layer (the fabric structure is 2 / 1 twill, and the square meter weight is 640g / m 2 , thickness 1.20mm, breaking strength (warp / weft) 9520 / 6480 (N / N), elongation at break (warp / weft) 29 / 23 (% / %));

[0103] (2) Mix ceramic particles with a particle size of 10nm-8μm with a polypropylene resin solution (polypropylene / xylene solution with a concentration of 0.01g / ml) to form a mixture, and the volume of the ceramic particles in the mixture accounts for 40% to 60% of the total volume, the mix...

Embodiment 2

[0109] (1) The continuous polyester fiber fabric structure of woven twill (the fabric structure is 2 / 1 twill, the square meter weight is 640g / m 2 , thickness 1.20mm, breaking strength (warp / weft) 9520 / 6480 (N / N), elongation at break (warp / weft) 29 / 23 (% / %)) impregnated in polypropylene resin (weight of polypropylene resin The average molecular weight is about 200,000, and the molecular weight distribution is about 7.8) solution (polypropylene / xylene solvent solution with a concentration of 0.01-0.3g / ml), take it out, cool down and solidify, and prepare a polypropylene resin layer coated on the surface. A fabric structure made of polyester fibers interwoven to obtain a layer of toughened structural material;

[0110] (2) Mix glass beads with a particle size of 10nm and polypropylene resin solution (polypropylene / xylene solution with a concentration of 0.3g / ml) to form a mixture, and the volume of the glass beads in the mixture accounts for 40% to 60% of the total volume, the m...

Embodiment 3

[0116] (1) Immerse the continuous Kevlar 49 fiber in the melt of polyamide 6 resin (the melt viscosity value of polyamide 6 is 0.6-0.7), take it out, cool and solidify at room temperature, and obtain polyamide 6 resin coated on the surface The continuous Kevlar 49 fiber is prepared into a continuous Kevlar 49 fiber fabric structure coated with a polyamide 6 resin layer through a weaving method to obtain a toughened structural material layer (the fabric structure is a plain weave structure with a thickness of 250μm);

[0117] (2) Mix ceramic particles with a particle size of 10 μm and polyamide 6 resin melt to form a mixture. The volume of the ceramic particles in the mixture accounts for 40% to 60% of the total volume of the mixture. By spraying, the The mixture is coated on the single-layer toughened structural material layer described in step (1), and after the polyamide 6 resin melt is cooled and solidified to room temperature at a cooling rate of 20°C / min, a reinforcing ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com