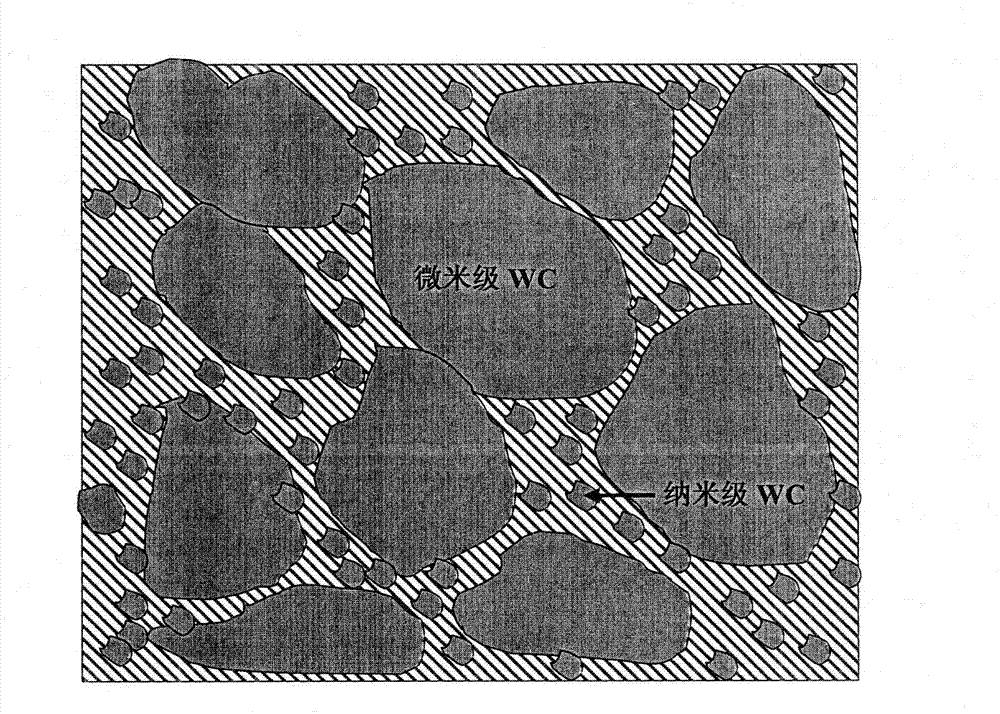

Micron-nano WC-Co hard alloy, preparation process and application thereof

A cemented carbide, micro-nano technology, applied in the field of its preparation, micro-nano WC-Co cemented carbide, can solve the problems of complex control of the second phase interface and difficult quality control, and achieve the effect of good strengthening and toughening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1 The preparation method of the micronano WC-Co cemented carbide is:

[0048] Prepare raw materials according to the following ratio:

[0049] Micro-nano WC composite powder 89%

[0050] Metal Co powder 10%

[0051]VC powder 1%

[0052] Toner <1%

[0053] And the raw materials are uniformly mixed in alcohol, wherein the micro-nano WC composite powder is prepared by mixing WC powder with a particle size of 5 microns and 100 nanometers in a ratio of 1:1;

[0054] Afterwards, use cemented carbide balls as grinding balls, the ball-to-material ratio is 1:5, the ball milling speed is 200 rpm, and the ball milling time is 48 hours;

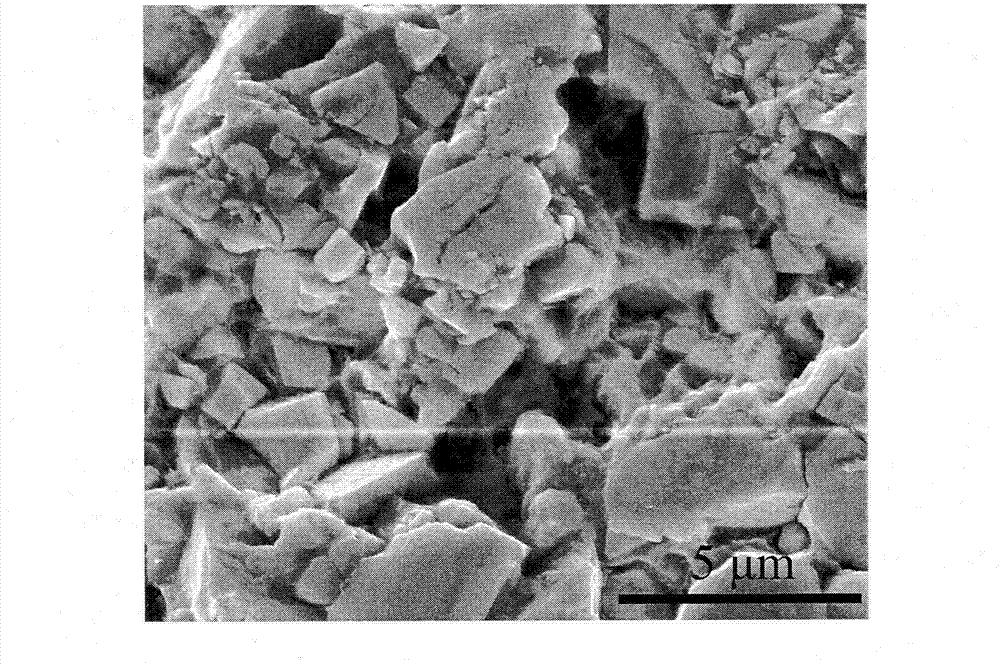

[0055] Then vacuum-dried, mixed with 3wt% polyvinyl alcohol binder relative to the weight percentage of the cemented carbide raw material, granulated, molded at 350 MPa, heated at 0.5 degrees per minute to 350 degrees for 3 hours, degreased for 3 hours, and vacuum sintered at 1350 degrees for densification. Obtain micro-nano WC-Co c...

Embodiment 2

[0057] Example 2: The difference between this example and Example 1 is that the mixing ratio of 5 microns and 100 nanometers of WC powder in the micro-nano WC composite powder is 1:2, and its mechanical properties are shown in Table 1.

Embodiment 3

[0058] Example 3: The difference between this example and Example 1 is that the mixing ratio of 5 microns and 100 nanometers of WC powder in the micro-nano WC composite powder is 1:3, and its mechanical properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com