Waterborne polyurethane super-hydrophobic coating and preparation method thereof

A water-based polyurethane and super-hydrophobic coating technology, applied in the field of coatings, can solve problems such as inability to use fabrics, hard coatings, and non-super-hydrophobic coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

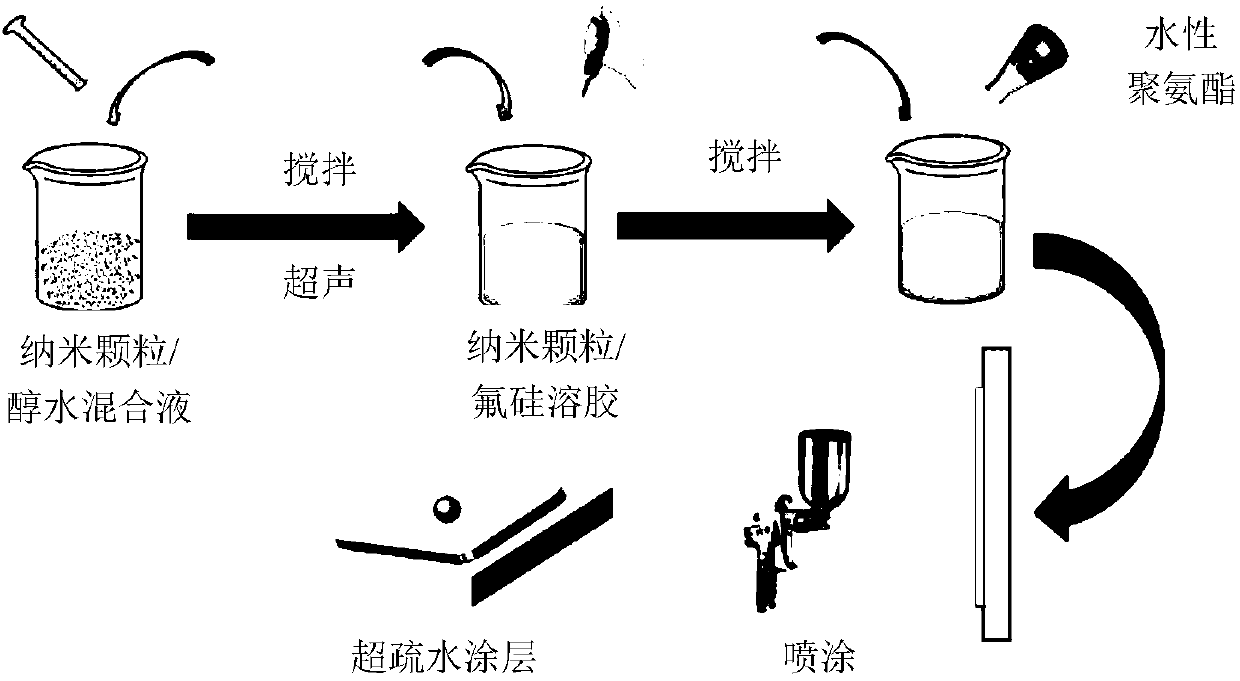

Method used

Image

Examples

Embodiment 1

[0025] (1) Add 2.5g nano-SiO to 40mL ethanol and 7mL water 2 (Zhejiang Wanjing New Material Co., Ltd., SP-30 type, that is, the average particle size is 30nm, the same below), mix evenly under magnetic stirring, ultrasonic 20min, and then add 0.8mL KH560, 0.8 For mLFAS-17, slowly adjust the pH value to about 10 with 25v% ammonia water, and continue to stir and react at room temperature for 30 minutes to obtain a mixed sol containing micro-nano particles, epoxy terminal groups and fluorine-containing short-chain siloxane.

[0026] (2) At room temperature, mix the above sol with 5mL water-based polyurethane emulsion (Hefei Anke Fine Chemical Co., Ltd., PU-116, anionic, solid content 30±1%), and stir magnetically at room temperature for 30 minutes to obtain a water-based polyurethane emulsion. Polyurethane superhydrophobic coating.

[0027] After rolling coating the coating on the glass surface (the liquid film thickness is 30 μm, the same below), bake at 80°C for 1 hour to obta...

Embodiment 2

[0029] (1) Add 2.5g nano-SiO to 40mL ethanol and 7mL water 2 , mix evenly under magnetic stirring, ultrasonic 20min, then add 0.8mL KH550, 0.8mLFAS-17 to the mixture, and react at room temperature for 30min to obtain siloxane mixed sol containing amine groups and fluorine-containing short chains.

[0030] (2) At room temperature, the above sol was mixed with 5 mL of water-based polyurethane emulsion PU-116, and magnetically stirred at room temperature for 30 minutes to obtain a water-based polyurethane superhydrophobic coating.

[0031] After rolling the coating on the glass surface, bake it at 80°C for 1 hour to form a super-hydrophobic coating with a static contact angle of 155.6° and a rolling angle of 4°. The bonding force between the coating and the glass is grade 0, and the surface hardness is 4H.

Embodiment 3

[0033] (1) Add 2.5g nano-SiO to 40mL ethanol and 7mL water 2 , mix well under magnetic stirring, ultrasonic 20min, then add 0.8mL KH560, 0.8mL tridecafluorooctyltriethoxysilane to the mixture, slowly adjust the pH value to about 10 with 25v% ammonia water, and react at room temperature After 30 minutes, a siloxane mixed sol containing epoxy groups and fluorine-containing short chains was obtained.

[0034] (2) At room temperature, the above sol was mixed with 4 mL of water-based polyurethane emulsion PU-116, and magnetically stirred at room temperature for 30 minutes to obtain a water-based polyurethane superhydrophobic coating. Coating and curing according to Example 1, the coating performance is similar to that of Example 1, that is, the static contact angle is 154.6°, and the rolling angle is 3.5°. The bonding force between the coating and the glass is grade 0, and the surface hardness is 4H.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com