Environment-friendly water-based drilling fluid and preparation method thereof

A water-based drilling fluid and environmental protection technology, applied in the field of drilling, can solve the problems of complex drilling fluid formula, difficult post-processing, difficult biodegradation, etc., and achieve the effect of ultra-low processing cost, outstanding economic benefits, and simple components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

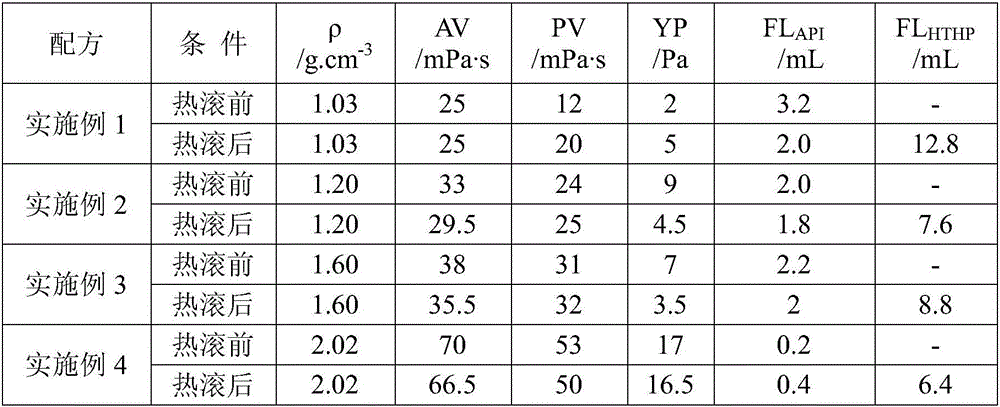

Embodiment 1

[0025] This example provides an environmentally friendly water-based drilling fluid without aggravation, which contains: 400g of fresh water, 12g of Huaian bentonite, 0.24g of sodium carbonate, 6g of environmentally friendly fluid loss reducer ZJSJ, 2g of fluid loss reducer B, low viscosity Carboxymethyl cellulose LV-CMC 0.8g, oligomeric alcohol amine ZJ-1 8g, environment-friendly anti-high temperature lubricant ZJSR 6g and 1500 mesh calcium carbonate powder 8g.

[0026] Among them, fluid loss reducer B is a high temperature resistant modified bentonite-based fluid loss reducer, which is composed of bentonite, water, cetyltrimethylammonium bromide, acrylamide, 2-acrylamide-2-methyl Propanesulfonic acid is synthesized according to the weight ratio of 1.5:7:0.3:0.8:0.2. Specifically, the high-temperature-resistant modified bentonite-based fluid loss control agent is synthesized through the following steps: Weigh 1.5 parts by weight of sodium-based bentonite and 7 parts by weight...

Embodiment 2

[0032] This embodiment provides a density of 1.2g / cm 3 Environmentally friendly water-based drilling fluid, which contains: 400g fresh water, 16g Huaian bentonite, 0.32g sodium carbonate, 6g environmentally friendly fluid loss reducer ZJSJ, 3g fluid loss reducer B, low viscosity carboxymethyl cellulose LV-CMC 1.2 g. 10g of oligomeric alcohol amine ZJ-1, 8g of environment-friendly anti-high temperature lubricant ZJSR, 3g of 40nm silicon dioxide, 5g of 1500 mesh calcium carbonate powder and 115g of barite powder.

[0033] Wherein, the fluid loss control agent B is a high temperature resistant modified bentonite based fluid loss control agent, which is the same as the fluid loss control agent B in Example 1.

[0034] The environmentally friendly water-based drilling fluid is prepared through the following steps:

[0035] (1) Add Huaian bentonite and a part of sodium carbonate into fresh water, stir for 20 minutes, and then pre-hydrate for 24 hours;

[0036] (2) Under the high-s...

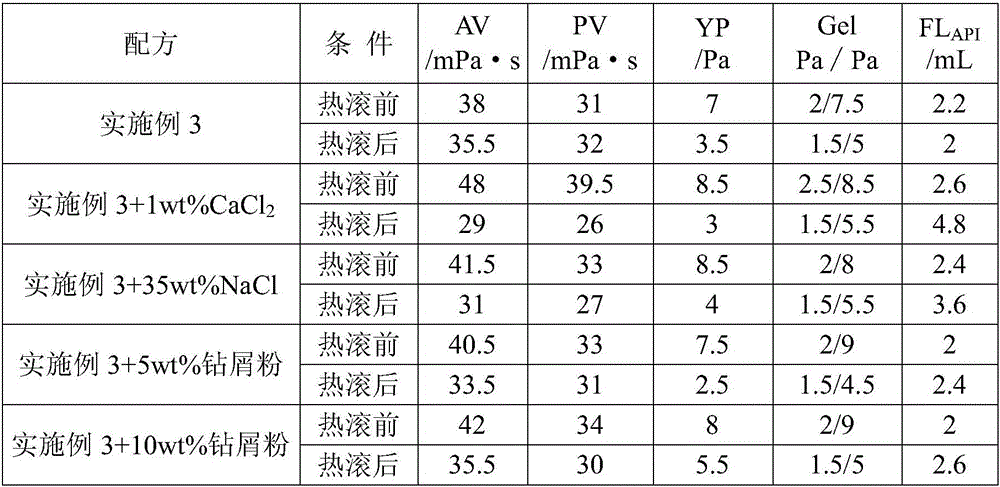

Embodiment 3

[0040] This embodiment provides a density of 1.6g / cm 3 Environmental protection water-based drilling fluid, which contains: fresh water 400g, Huaian bentonite 16g, sodium carbonate 0.32g, environment-friendly fluid loss additive ZJSJ 8g, fluid loss additive B 2g, low viscosity carboxymethyl cellulose LV-CMC 1.8 g, oligomeric alcohol amine ZJ-1 10g, environment-friendly anti-high temperature lubricant ZJSR 12g, 1000 mesh calcium carbonate powder 4g, 2000 mesh calcium carbonate powder 8g and barite powder 425g.

[0041] Wherein, the fluid loss control agent B is a high temperature resistant modified bentonite based fluid loss control agent, which is the same as the fluid loss control agent B in Example 1.

[0042] The preparation steps of the environment-friendly water-based drilling fluid are the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com