Super-hydrophobic wire mesh and preparation method thereof

A wire mesh and wire mesh carrier technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., to achieve the effects of low preparation cost, good mechanical properties, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

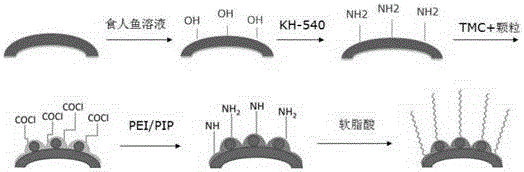

Method used

Image

Examples

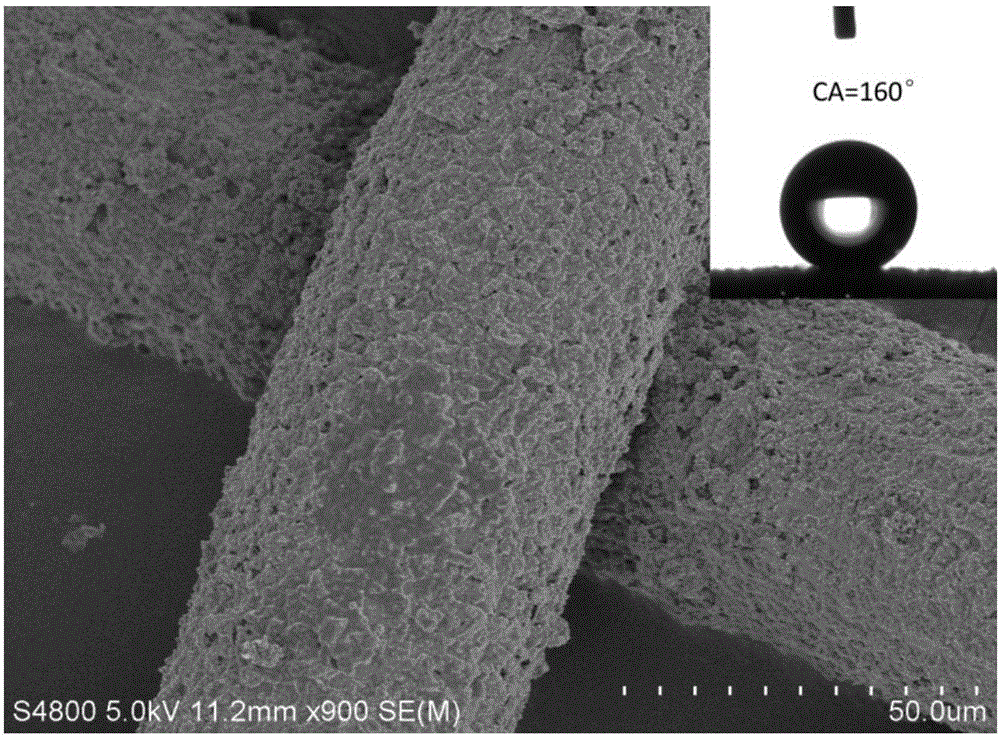

Embodiment 1

[0064] (1) Cut the wire mesh into small pieces of 2*2cm, ultrasonically clean them with dichloromethane and water for 30 minutes, and then dry them in the air or place them in an oven at 80°C to dry.

[0065] (2) Configuration of piranha solution: prepare concentrated sulfuric acid and hydrogen peroxide at a volume ratio of 2:1, and slowly add hydrogen peroxide into concentrated sulfuric acid.

[0066] (3) Soak the cleaned and dried wire mesh in the piranha solution, let it stand for 30 minutes, and then wash it with deionized water.

[0067] (4) Configuration of silane coupling agent solution: Add 1.5g of KH-540 into 30ml of toluene solvent.

[0068] (5) Soak the cleaned and dried wire mesh in the silane coupling agent, soak it under magnetic stirring for 24 hours, take it out, wash it with deionized water three times after taking it out, and finally put it in a vacuum drying oven and dry it at 80°C two hours.

[0069] (6) Preparation of oil phase solution: 0.2 g of trimeso...

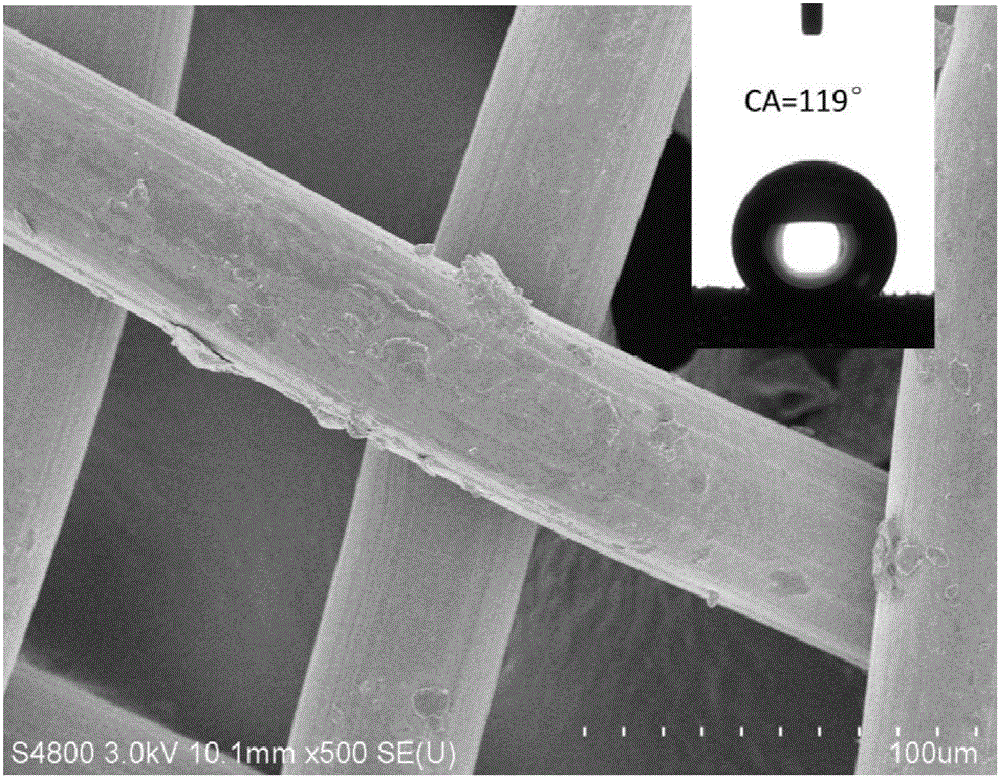

Embodiment 2

[0076] (1) Cut the wire mesh into small pieces of 2*2cm, ultrasonically clean them with dichloromethane and water for 60 minutes, and then dry them in the air or place them in an oven at 80°C to dry.

[0077] (2) Configuration of piranha solution: prepare concentrated sulfuric acid and hydrogen peroxide at a volume ratio of 2:1, and slowly add hydrogen peroxide into concentrated sulfuric acid.

[0078] (3) Soak the cleaned and dried wire mesh in the piranha solution, let it stand for 30 minutes, and then wash it with deionized water. (4) Configuration of silane coupling agent solution: Add 1.5g of KH-540 into 30ml of toluene solvent.

[0079] (5) Soak the cleaned and dried wire mesh in the silane coupling agent, soak it under magnetic stirring for 24 hours, take it out, wash it with deionized water three times after taking it out, and finally put it in a vacuum drying oven and dry it at 80°C two hours.

[0080] (6) Preparation of aqueous phase solution: 4 grams of triethylam...

Embodiment 3

[0089] (1) Cut the wire mesh into small pieces of 2*2cm, ultrasonically clean them with dichloromethane and water for 40 minutes, and then dry them in the air or place them in an oven at 80°C to dry.

[0090] (2) Configuration of piranha solution: prepare concentrated sulfuric acid and hydrogen peroxide at a volume ratio of 2:1, and slowly add hydrogen peroxide into concentrated sulfuric acid.

[0091] (3) Soak the cleaned and dried wire mesh in the piranha solution, let it stand for 30 minutes, and then wash it with deionized water.

[0092] (4) Configuration of silane coupling agent solution: Add 1.5g of KH-540 into 30ml of toluene solvent.

[0093] (5) Soak the cleaned and dried wire mesh in the silane coupling agent, soak it under magnetic stirring for 24 hours, take it out, wash it with deionized water three times after taking it out, and finally put it in a vacuum drying oven and dry it at 80°C two hours.

[0094] (6) Preparation of aqueous phase solution: 6 grams of m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com