Device and method for realizing laser cavitating cleaning micro-nano-particles on surface of material

A micro-nano particle and laser technology, applied in chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as documents and patents that have not been retrieved, achieve better, more convenient and accurate measurement results, improve processing efficiency, and reduce dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

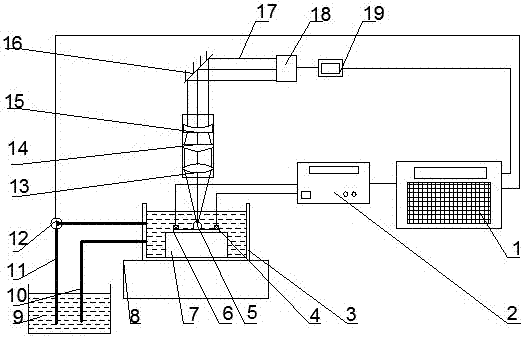

[0018] Embodiment: Install the silicon chip on the clamping device, the silicon chip is placed in the container that deionized water is housed, the movement of the silicon chip is controlled by the three-dimensional mobile platform 8, and the laser is adjusted to focus on the upper side of the silicon chip surface, wherein the pulse Nd: The process parameters of the YAG laser are: the output wavelength is 1.06 μm, and the pulse width is 10 ns. Utilize the computer 1 to inject water into the water tank 3 through the liquid pump 12, control the displacement of the water pump 12, ensure that the liquid in the water tank 3 circulates and maintains a constant capacity;

[0019] Adjust the parameters of the laser 18 by the laser controller 19, adjust the three-dimensional mobile platform 8 by the computer 1 to determine the position of the laser cavitation cleaning of the workpiece 6 and the distance between the cavitation 5 at the focus position; When laser cavitation is generated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com