Lubrication grease composition and preparation method thereof

A grease composition and a technology for polyurea-based grease are applied to grease compositions and their preparation, and the field of polyurea-based grease compositions can solve the problem that urea-based structures do not have the ability to carry high loads, friction and wear, The problem of poor anti-wear and anti-wear effect, etc., achieves the effects of excellent water-spray resistance, long colloidal stability, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

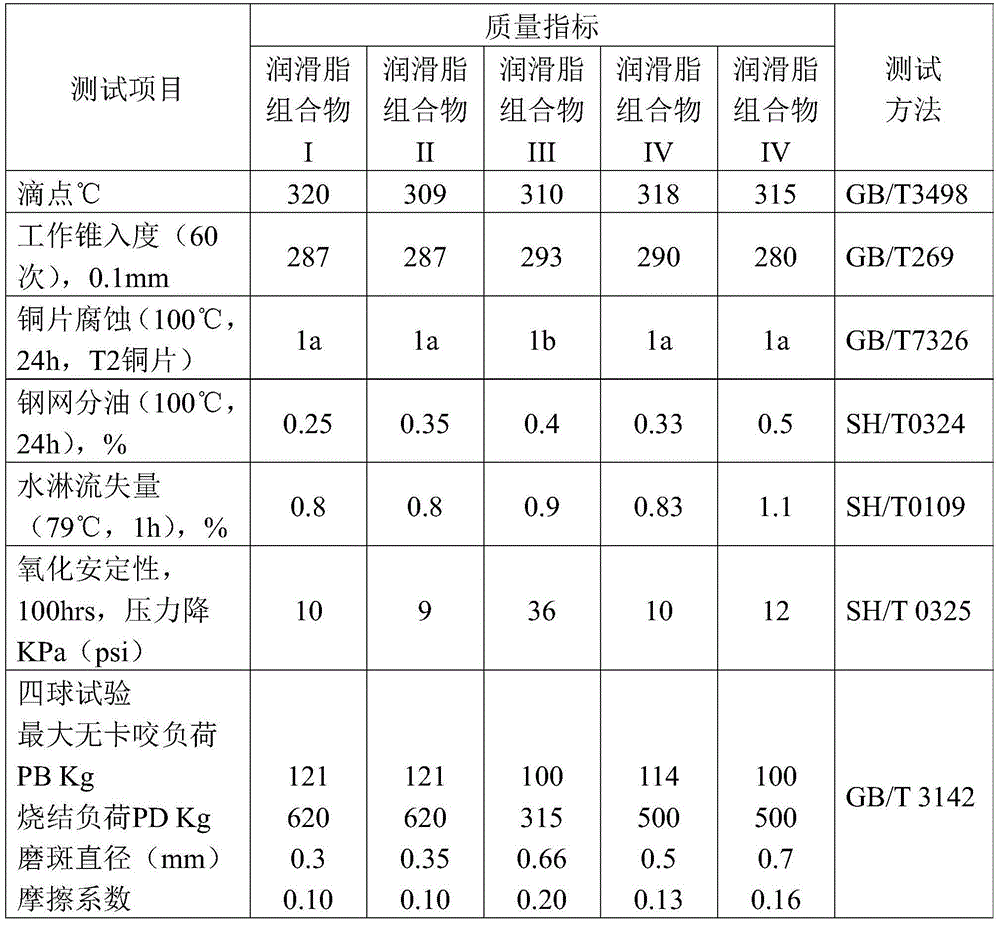

Examples

Embodiment 1

[0048] Mix 420 parts of trimellitate TMT-4 (Liaocheng Ruijie Chemical Co., Ltd., the same below) with 35.04 parts of diphenylmethane-4,4-diisocyanate (Aike Reagent) in a grease preparation kettle , heated to 70°C to dissolve; at the same time, add 512 parts of polyalphaolefin SpectraSyn 40 and 7.92 parts of octadecylamine (Shanghai Zhixin Chemical Co., Ltd.) to another reaction kettle, heat to 70°C to dissolve, and then add 6.67 parts of aniline (Shandong Haihua Co., Ltd.) and 17.76 parts of cyclohexylamine (Nantong Yitong Chemical Co., Ltd.), stirring to make it dissolve; the mixed solution in the reaction kettle is quickly dropped into the preparation kettle, the fan is turned on, and after stirring at a constant temperature for 10 minutes, Raise the temperature to 150°C and keep it warm for 20 minutes; cooling, grinding, homogenizing and degassing to obtain polyurea-based grease.

[0049] Add 100 parts of the above-mentioned polyurea-based grease into the pre-cleaned normal...

Embodiment 2

[0051] Add 100 parts of the above-mentioned polyurea-based grease into the pre-cleaned normal pressure reactor, heat up and stir, add 1 part of potassium triborate neutral oil dispersion Octopol PTB, 1 part of butyl / octyl diphenylamine Irganox L57, 4 parts of tackifier ethylene-propylene copolymer T614 (Jinzhou Runda Chemical Co., Ltd.), 2 parts of polytetrafluoroethylene and 3 parts of nano-calcium carbonate, mixed and stirred, then heated to 110 ° C, stirred at constant temperature for 40 minutes, cooled out of the kettle , homogeneously ground and packaged to obtain grease composition II.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com