Patents

Literature

31results about How to "Reduce or even eliminate pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

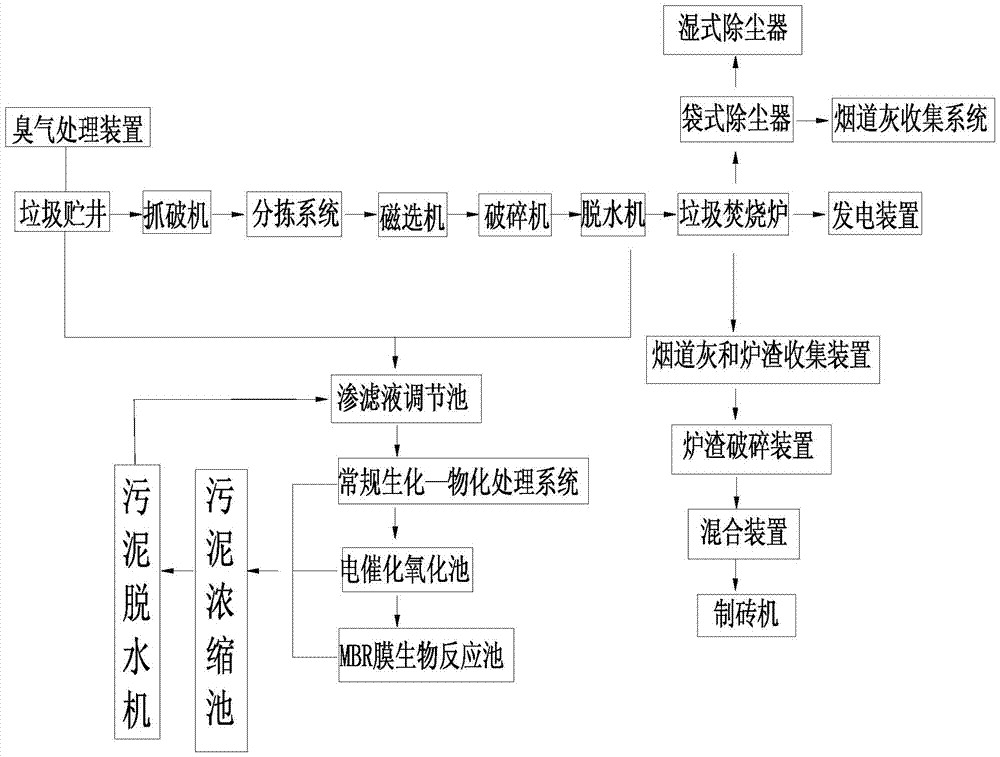

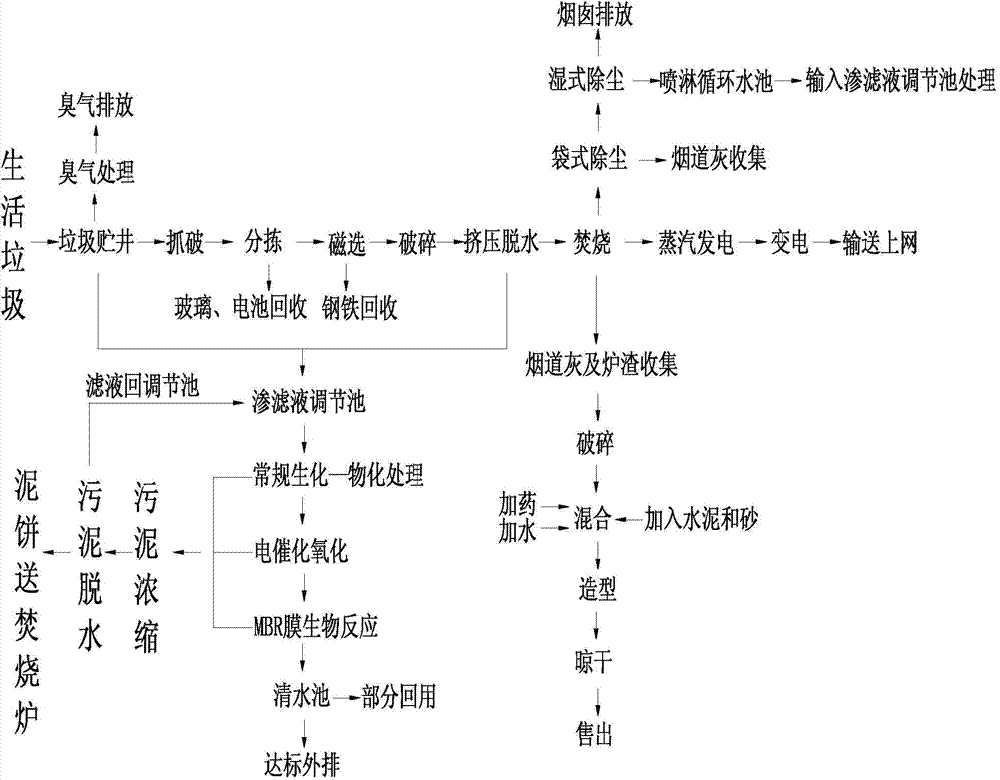

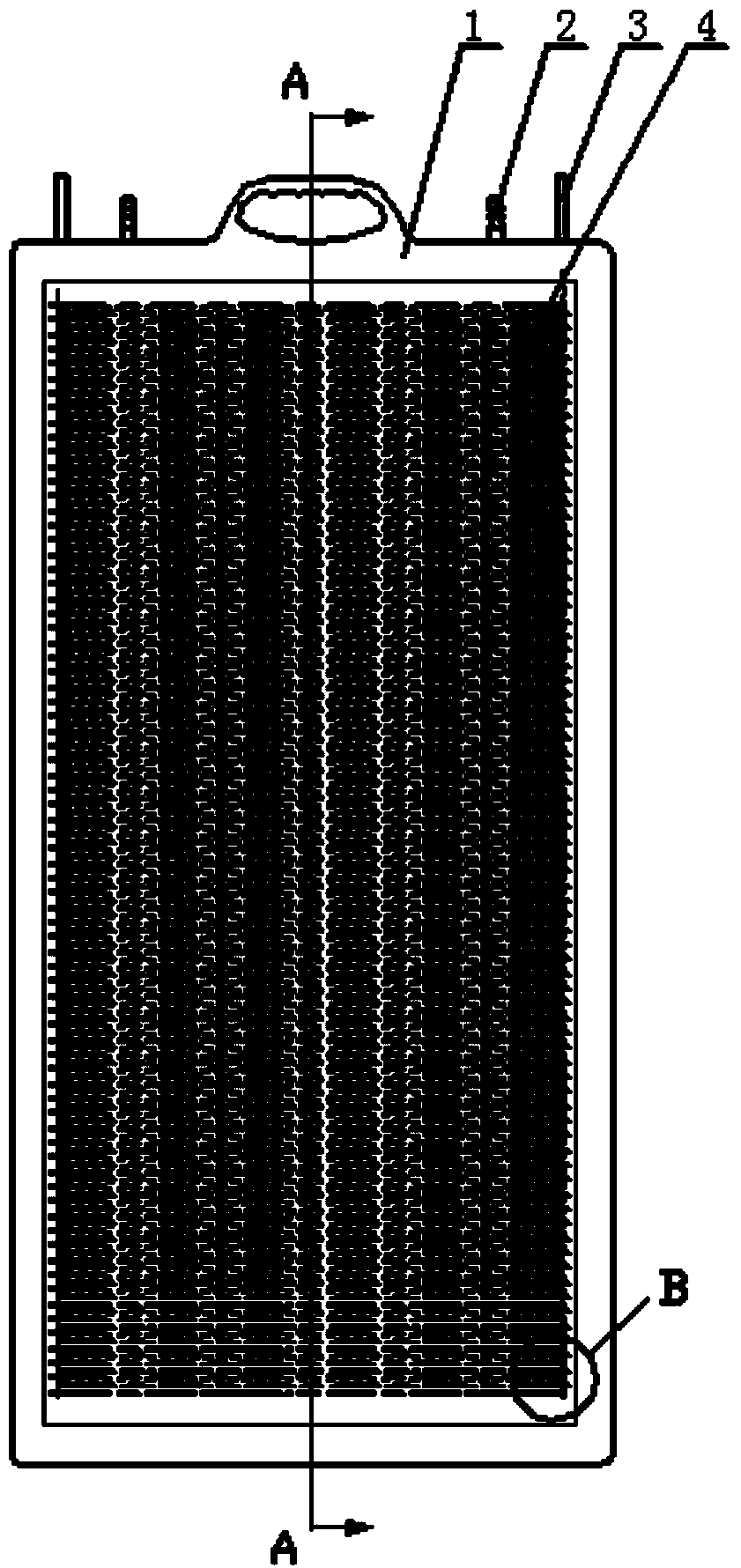

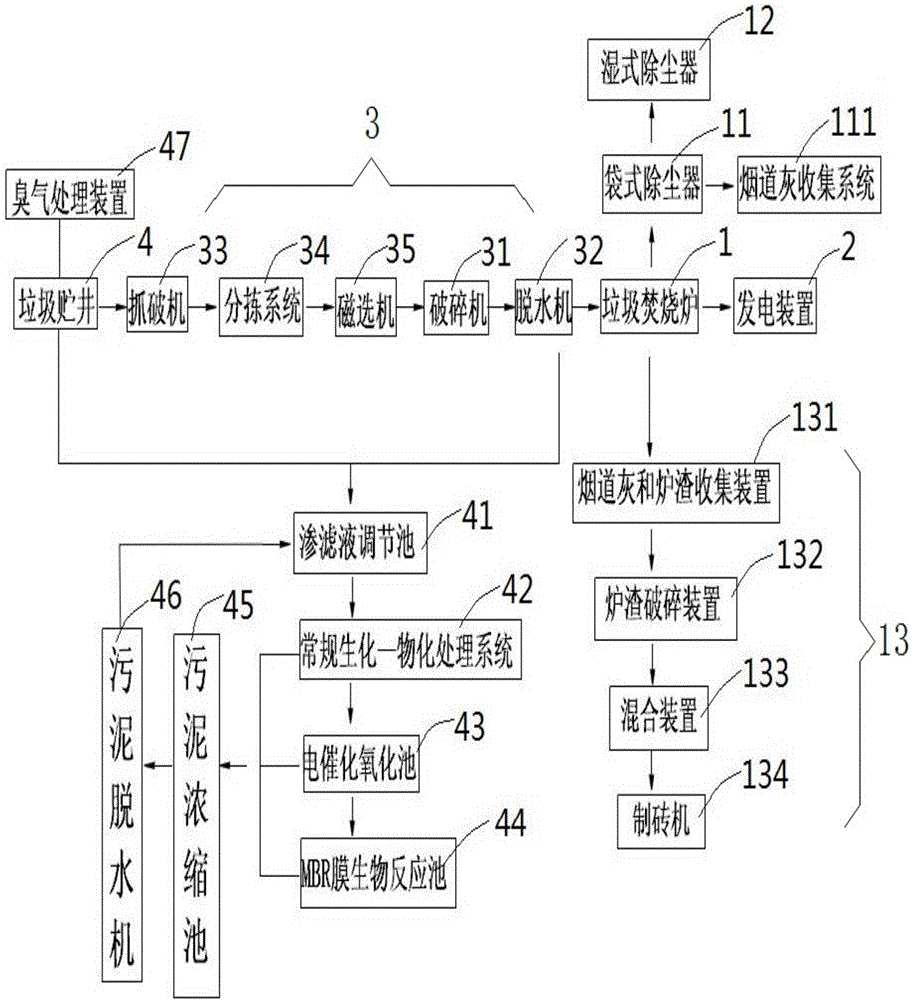

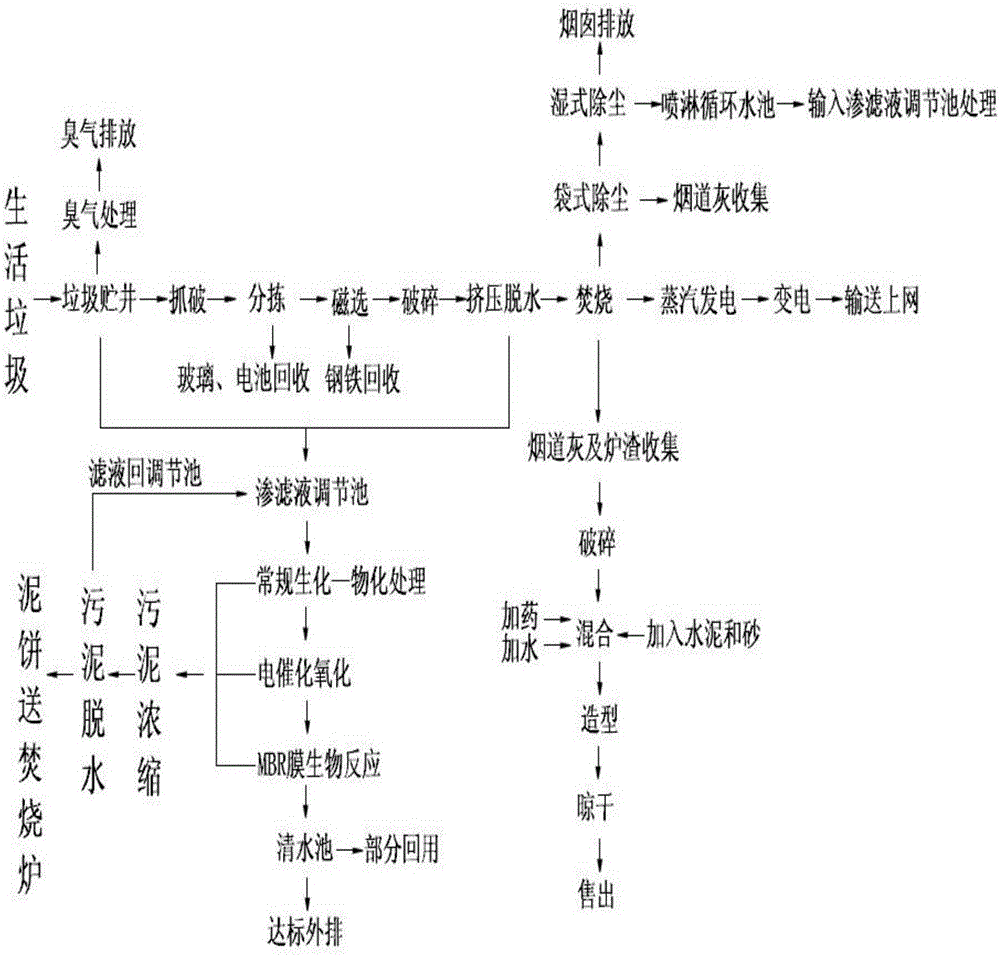

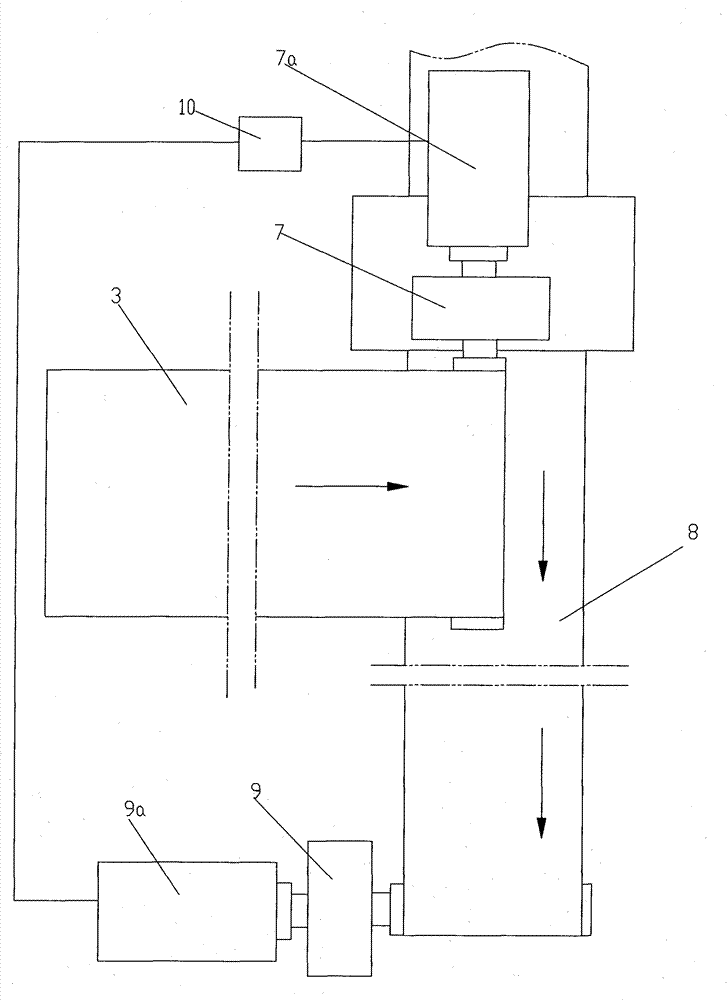

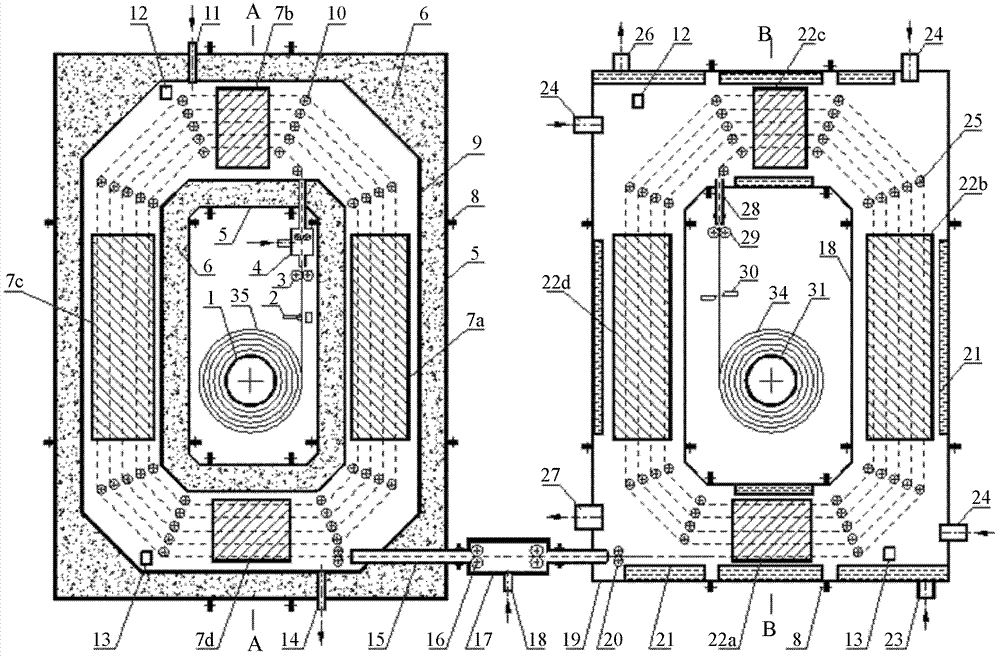

Environment-friendly device matched with efficient and pollution-free refuse incineration power generation and using technology thereof

ActiveCN103900090AGuaranteed normal processingReduce pollutionCombination devicesMultistage water/sewage treatmentSlagCollection system

The invention relates to the technical field of refuse incineration power generation and particularly discloses an environment-friendly device matched with efficient and pollution-free refuse incineration power generation and a using technology of the environment-friendly device matched with efficient and pollution-free refuse incineration power generation. On the basis of an existing refuse incineration power generation system, a pre-treatment system, a flue gas treatment system and a leachate treatment system are additionally arranged. The pre-treatment system comprises a scratching machine, a sorting system, a magnetic separator, a crusher and a dehydrator. The flue gas treatment system comprises a bag type dust collector and a wet type dust collector, and a slag outlet of the bag type dust collector is provided with a flue dust collecting system. A leachate adjusting pool is sequentially connected with a convectional biochemical-physicochemical treatment system, an electrocatalytic oxidation pool and a membrane biological reaction pool. Through the environment-friendly device matched with efficient and pollution-free refuse incineration power generation and the using technology of the environment-friendly device matched with efficient and pollution-free refuse incineration power generation, generation of dioxin precursors is greatly reduced or even eliminated, and therefore first, pollution is reduced, and second, waste treatment cost is reduced and the national emission standard can be reached. The environment-friendly device matched with efficient and pollution-free refuse incineration power generation has prominent innovation, the generating capacity is improved by more than 1.5 times, and the tough problem of environmental pollution is solved comprehensively and thoroughly.

Owner:深圳市宇力科技有限公司

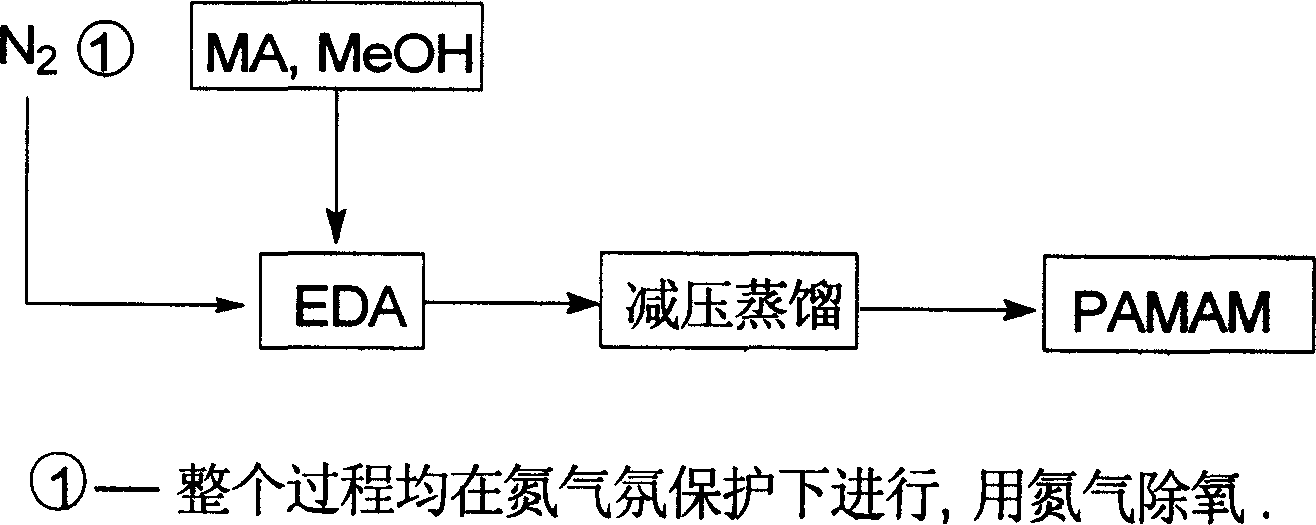

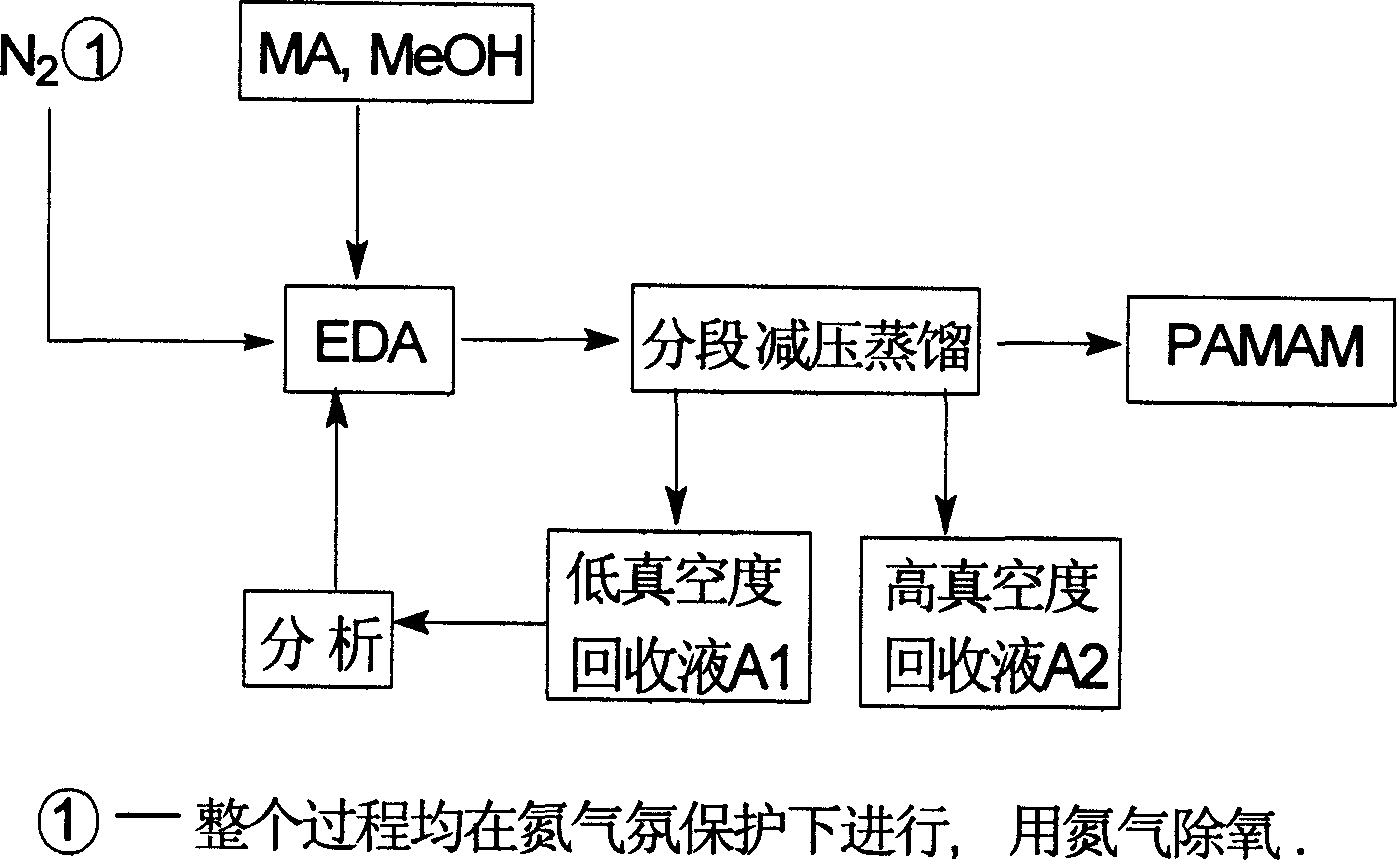

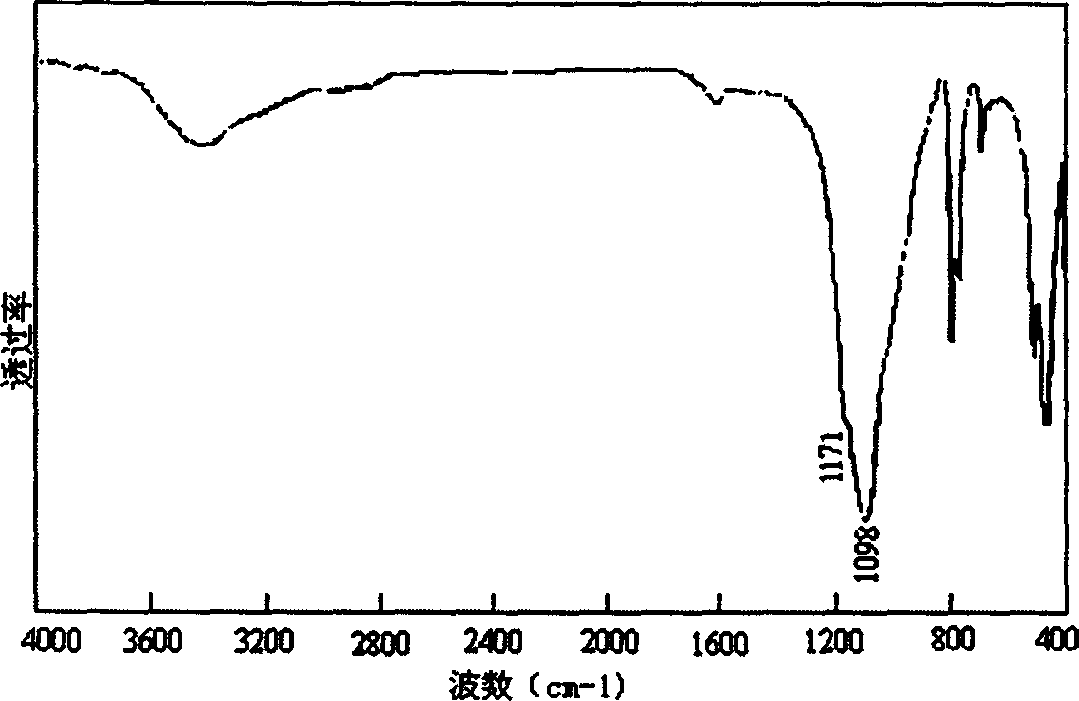

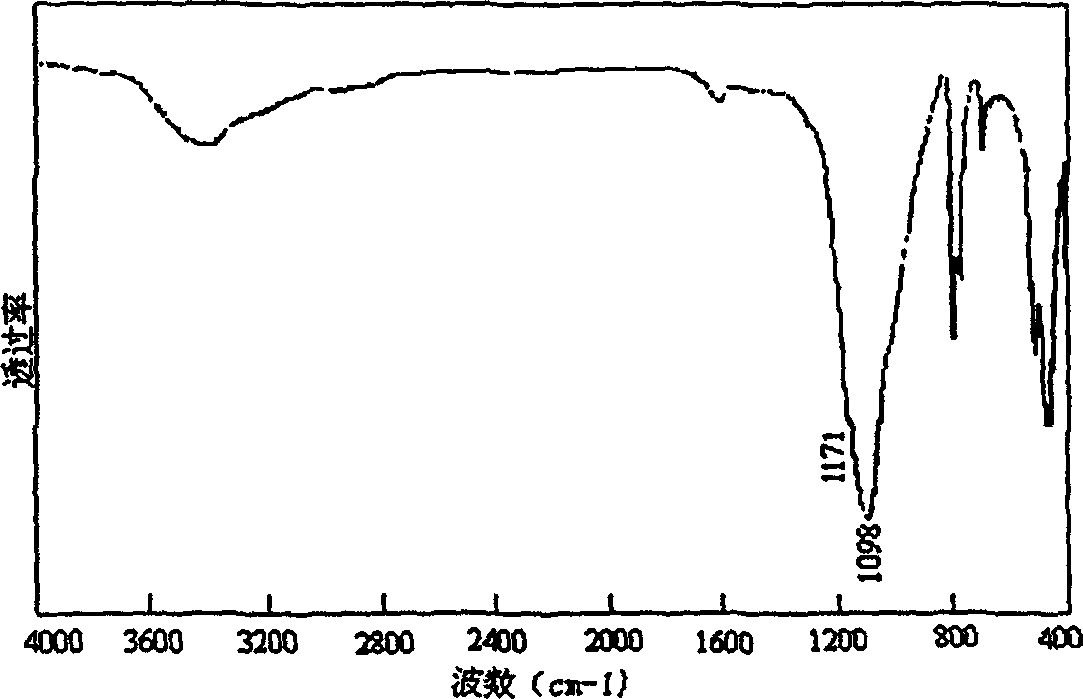

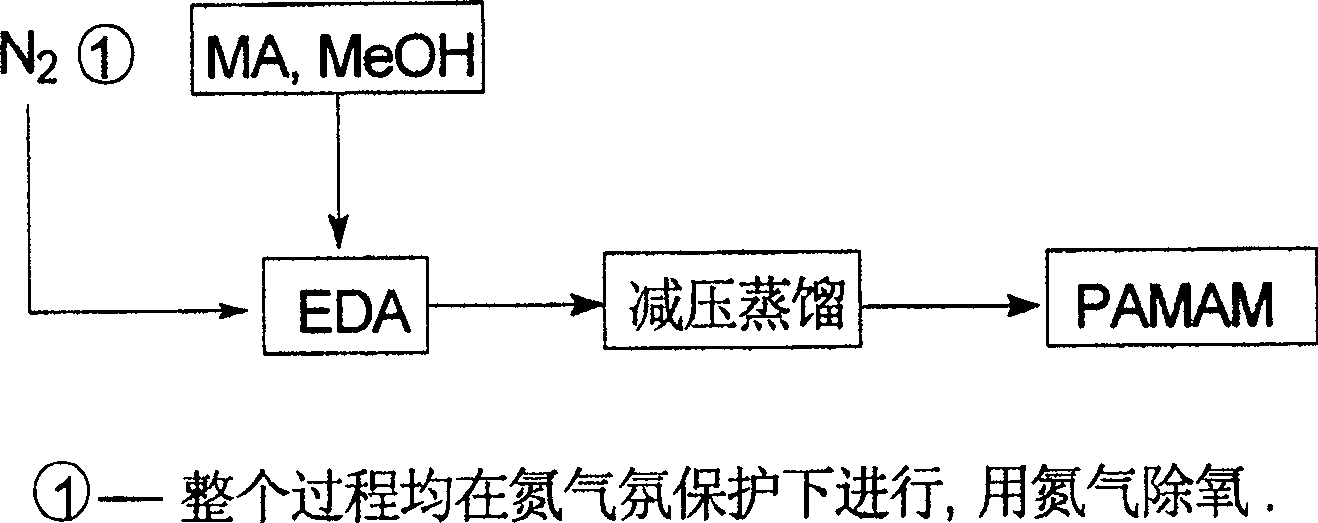

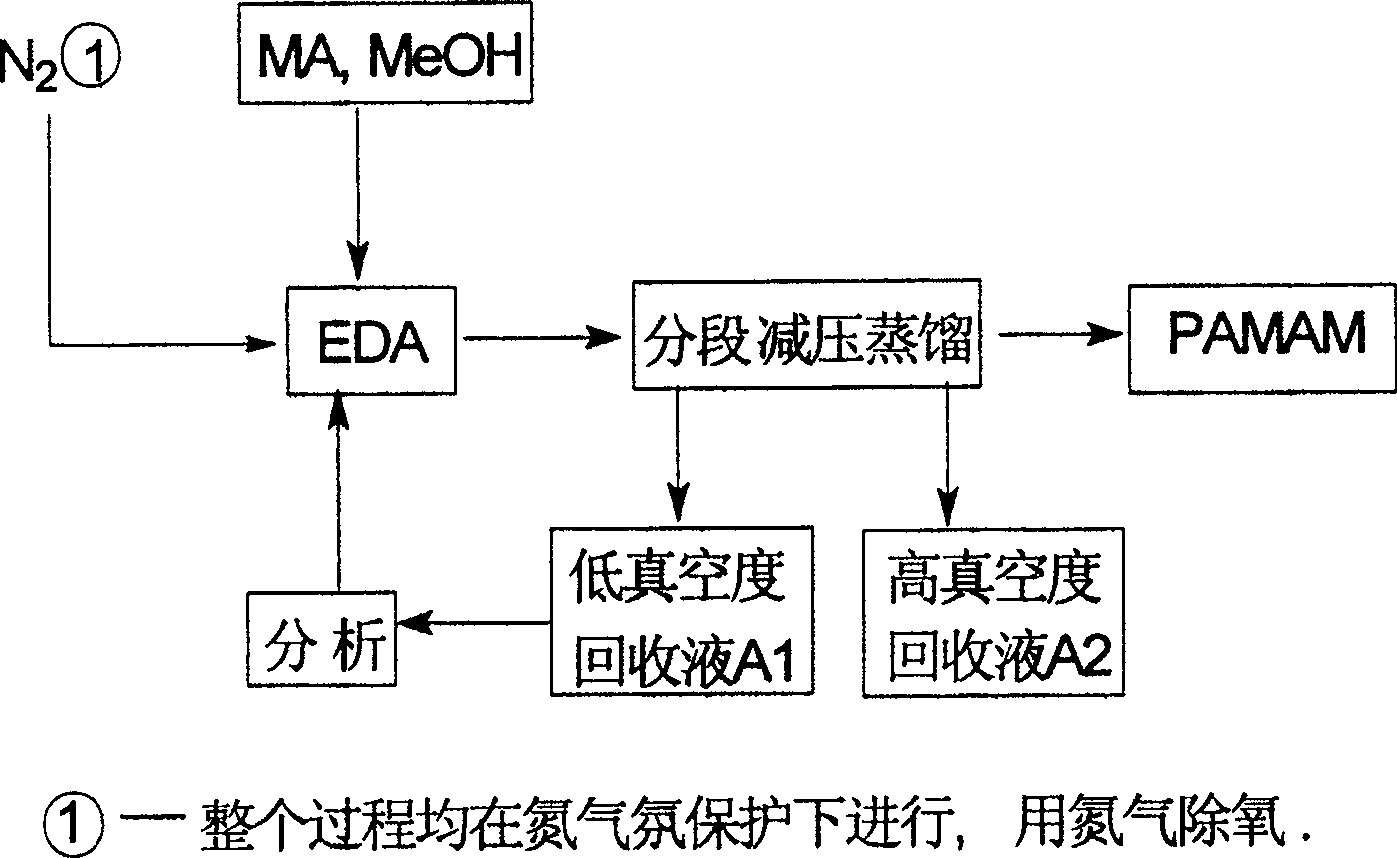

Green synthesis process of polyamide-dendritic amine polymer

The green synthesis process of dendritic polyamide-amine (PAMAM) polymer has material methyl acrylate (MA0 and ethylene diamine (EDA) in such amount that the ratio of MA or EDA to PAMAM end group matter is 5-8. The present invention has increased material amount to result in decreased reaction side product, raised purity of destination product, no polymerization in synthesizing high algebraic PAMAM and improved product quality. The present invention has high liquid recovering rate, less pollution, simplified technological process, low synthesis cost, low equipment cost and low power consumption, and reaches the aim of green production.

Owner:HUNAN UNIV OF SCI & TECH

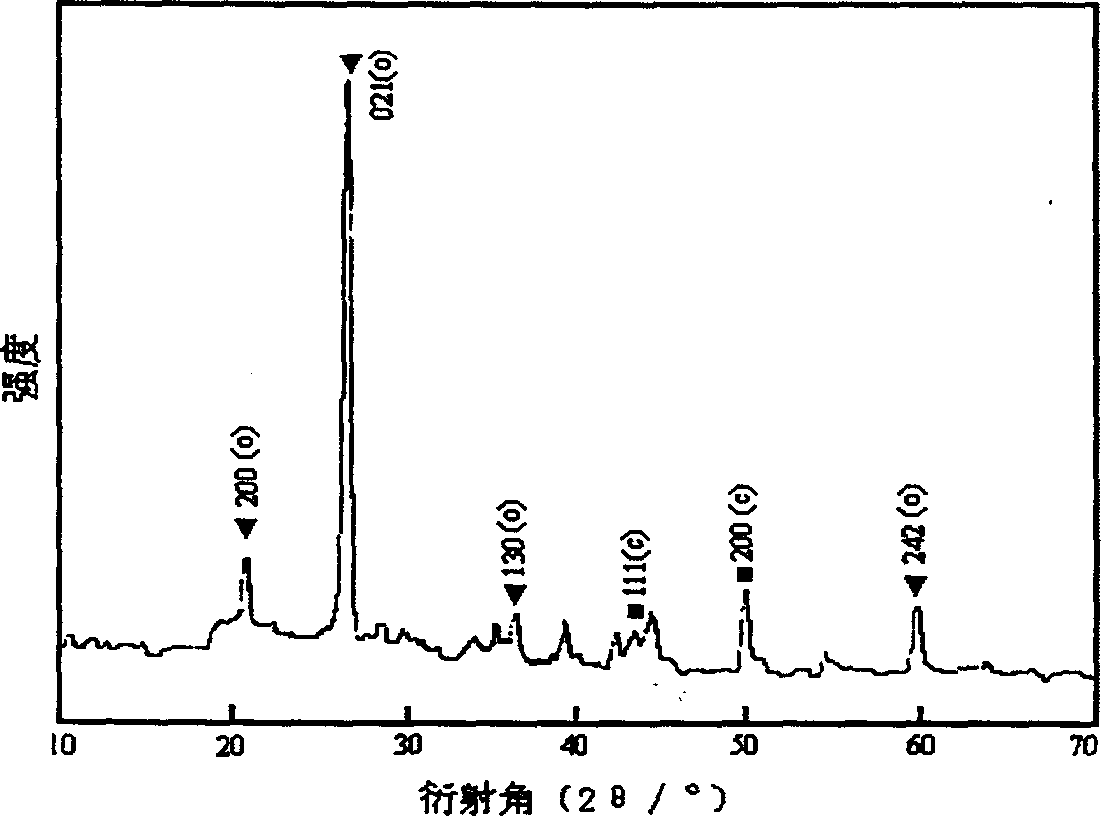

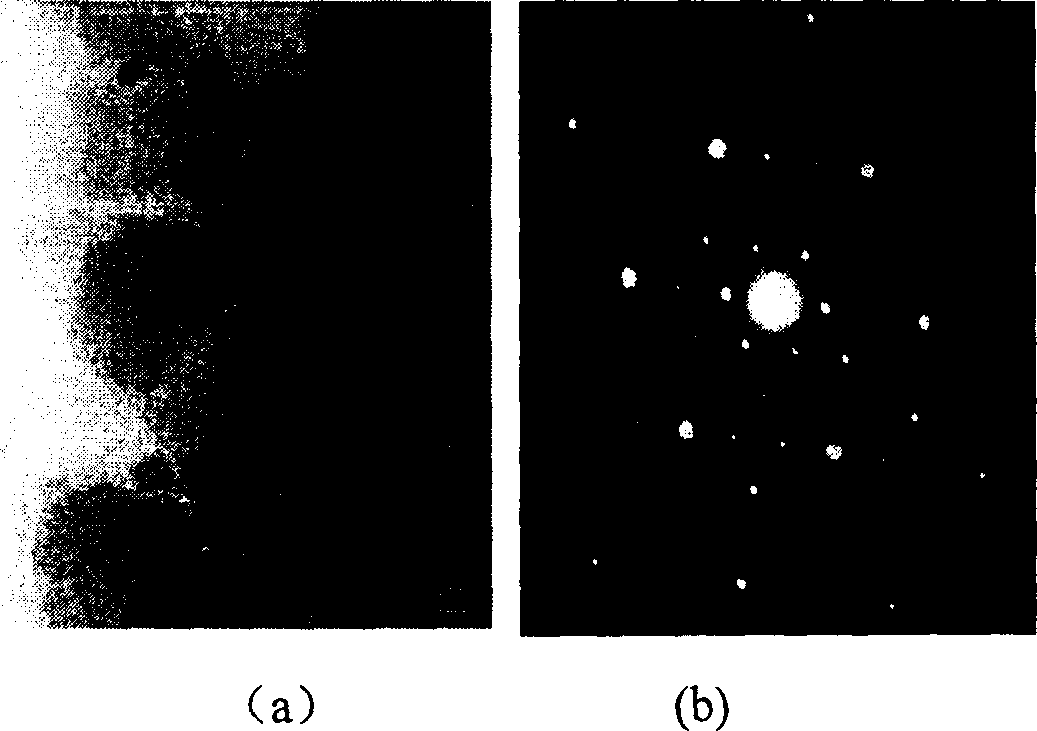

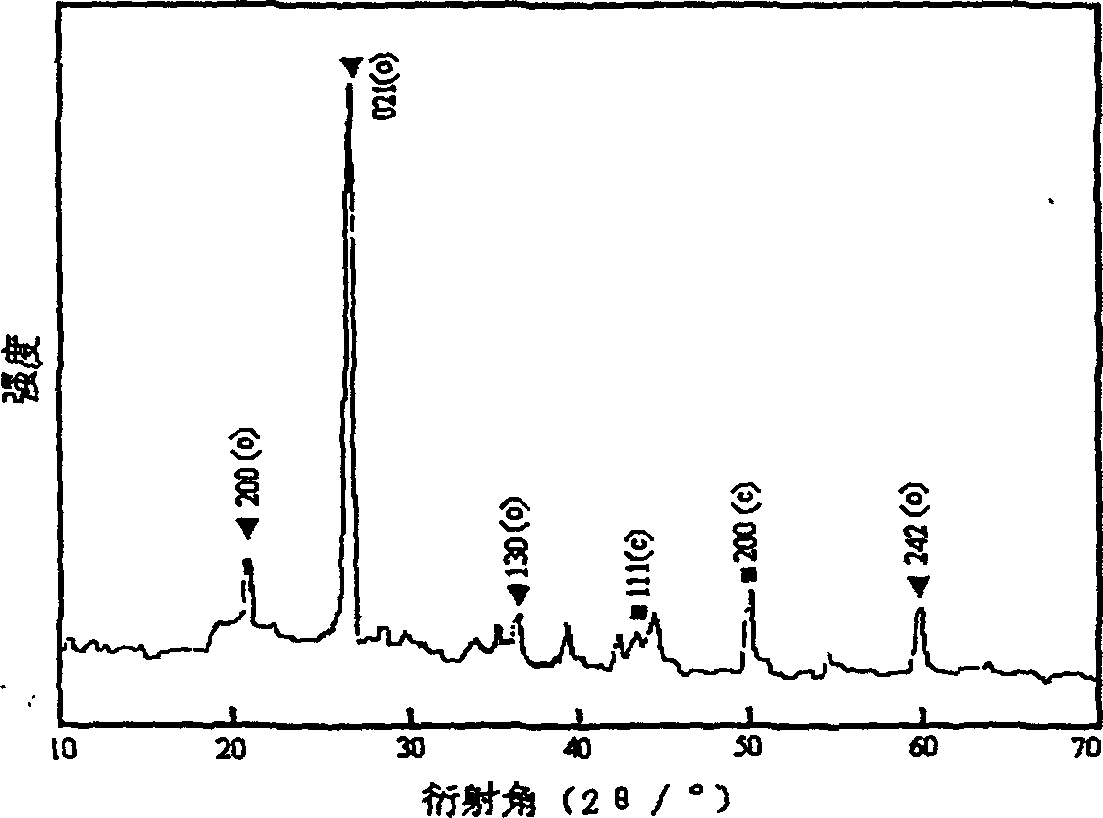

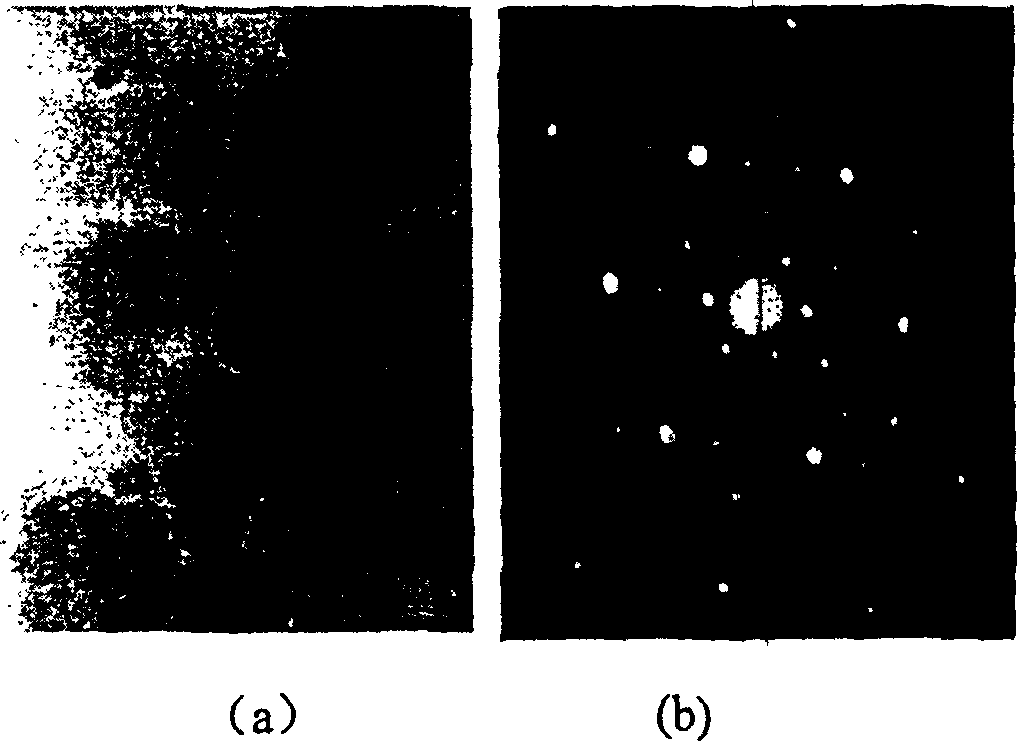

Method for synthesizing crystallites and block crystals of nitride by multistep reaction in-situ under hydrothermal condition

InactiveCN1431145AEliminate pollutionStrong controllabilityNitrogen-metal/silicon/boron binary compoundsBulk crystalMetal

A process for preparing microcrystal and bulk crystal of nitride by in-situ multi-step reaction in hydrothermal condition features that in constant temp and pressure condition, the raw materials are supplemented into reaction system continuously or multiple times for controlling the generation of crystal nuclears and the growth of crystals, and a novel reducer (hydrazine hydrate) is used to prevent the pollution of by-product to microcrystal and crystal. Its advantage is uniform granularity.

Owner:SHANDONG UNIV

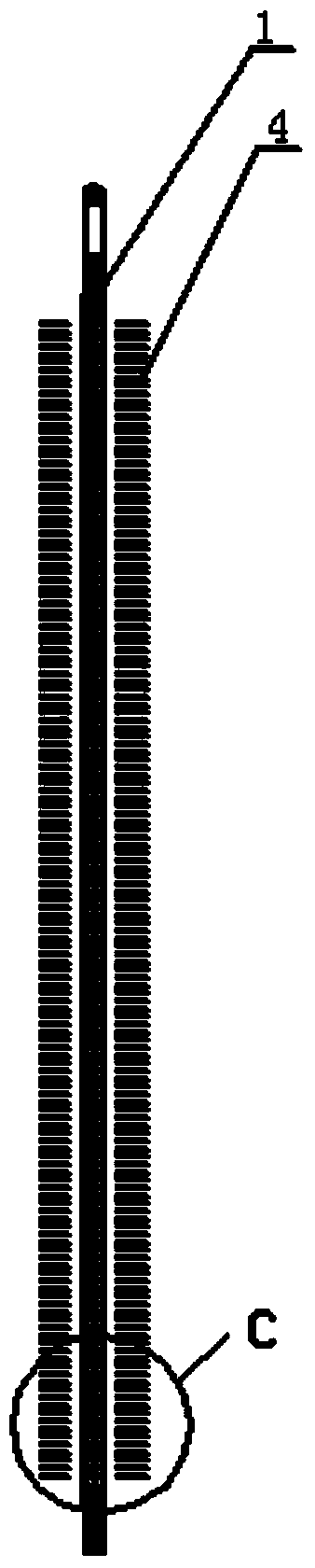

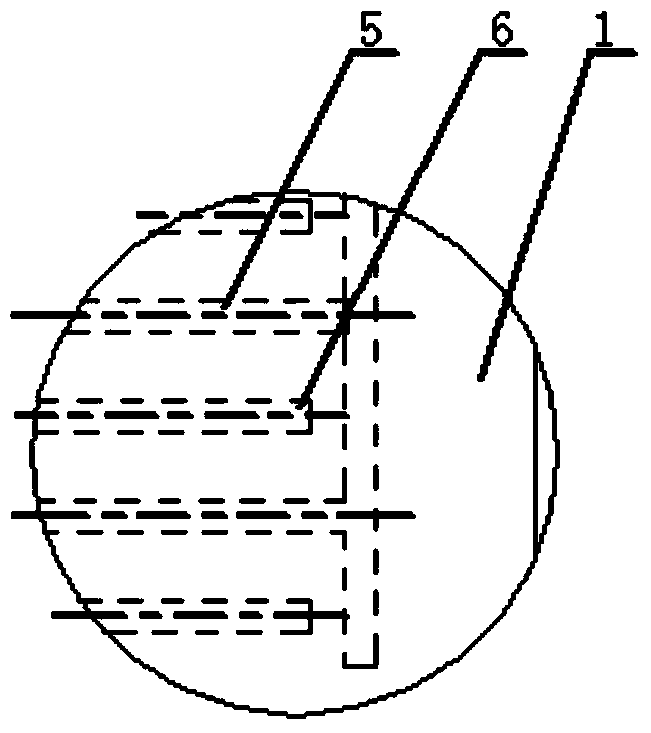

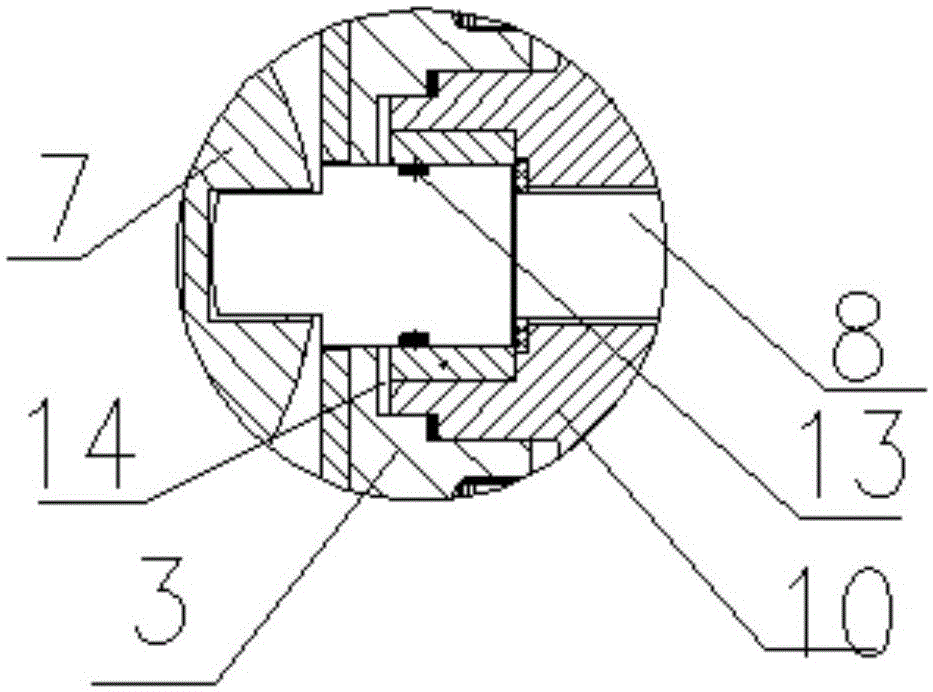

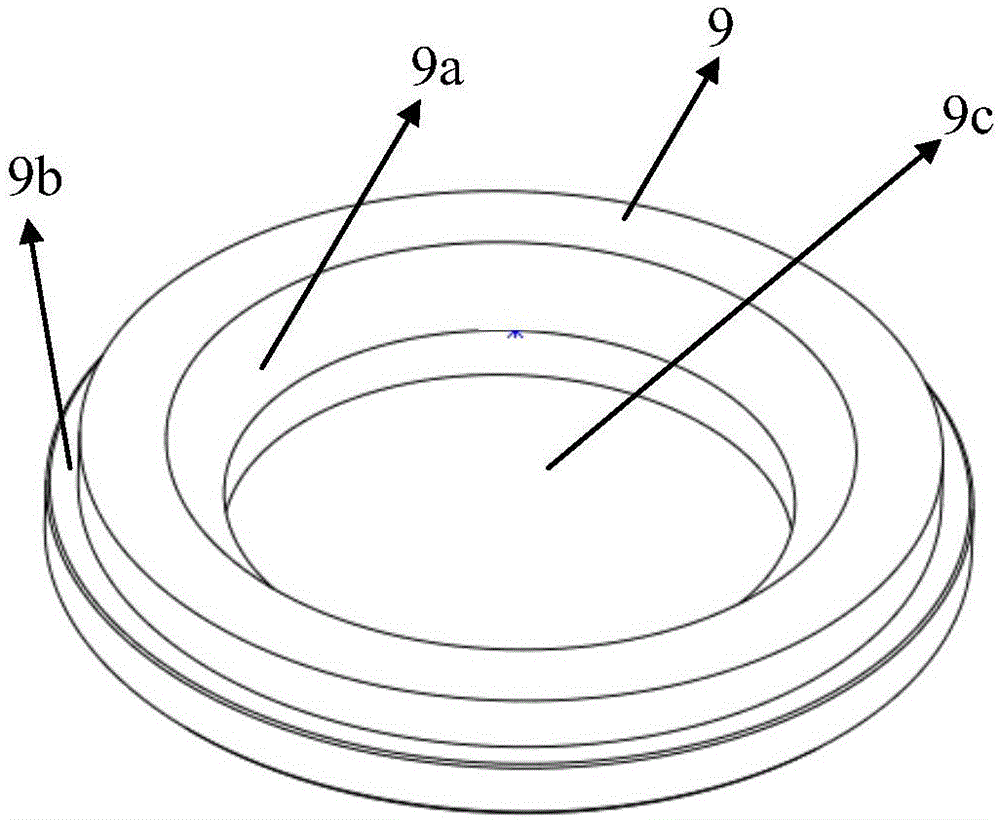

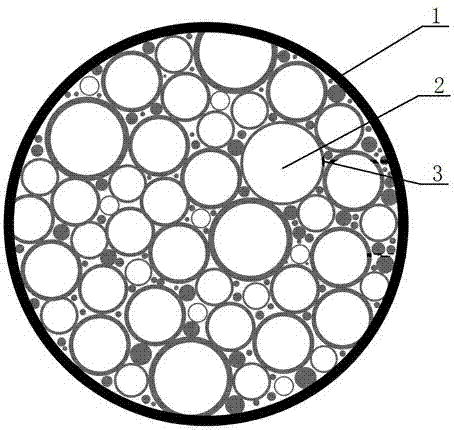

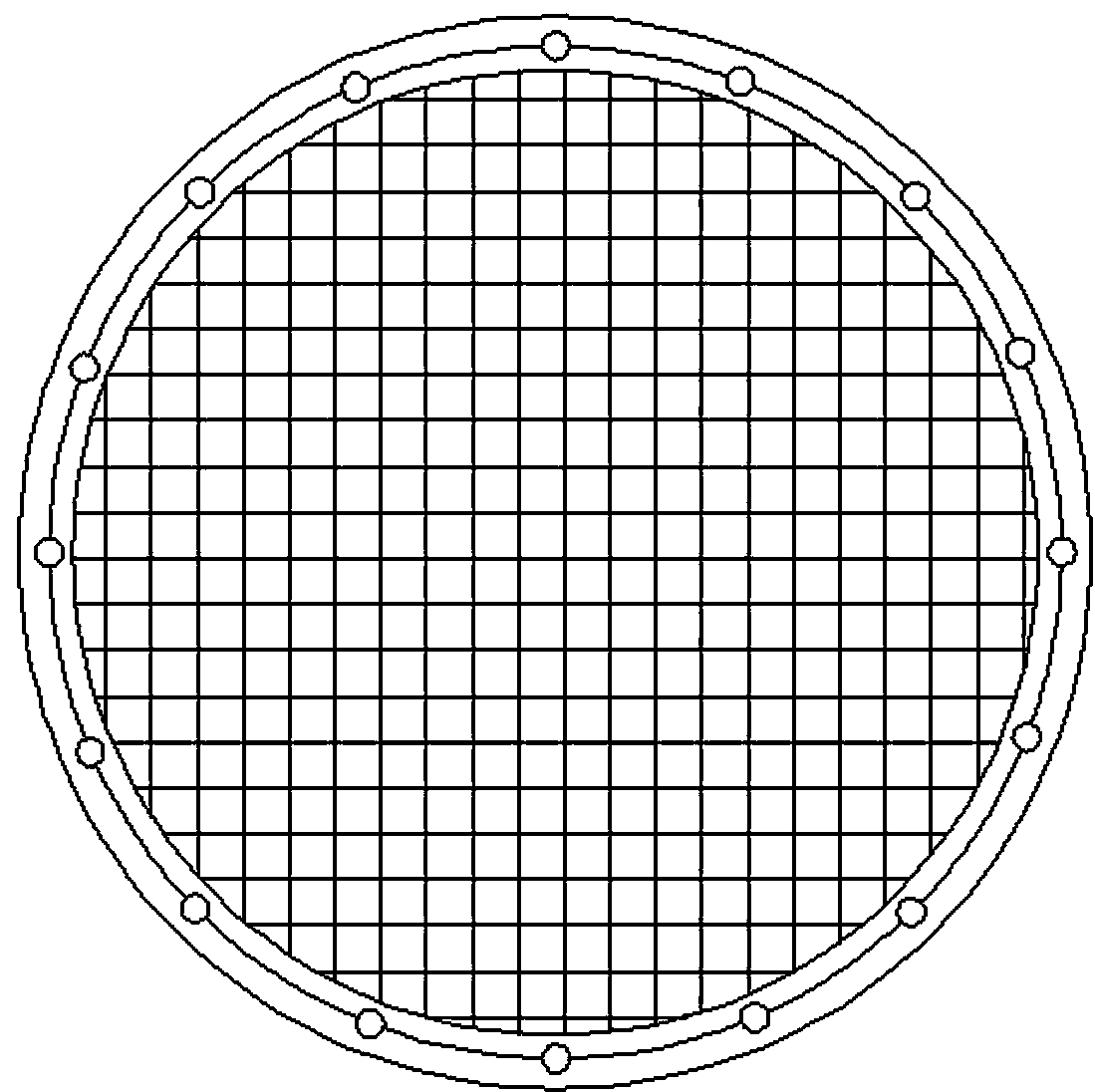

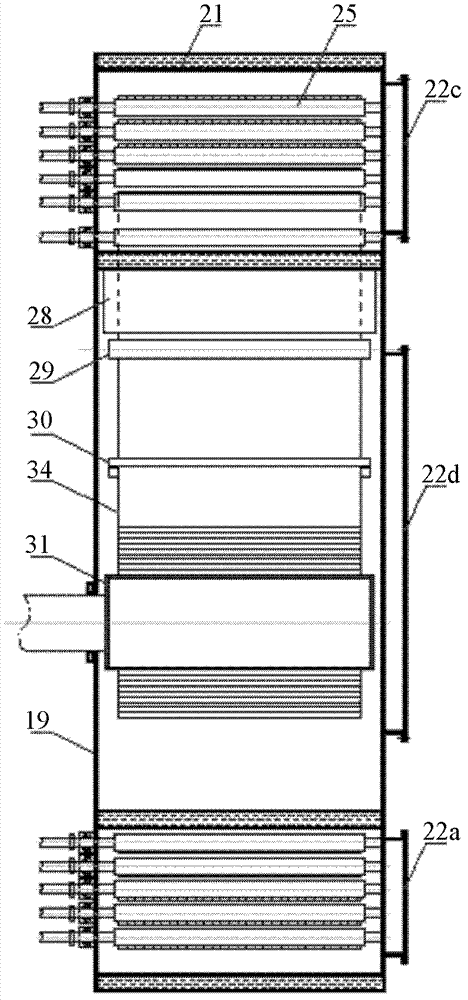

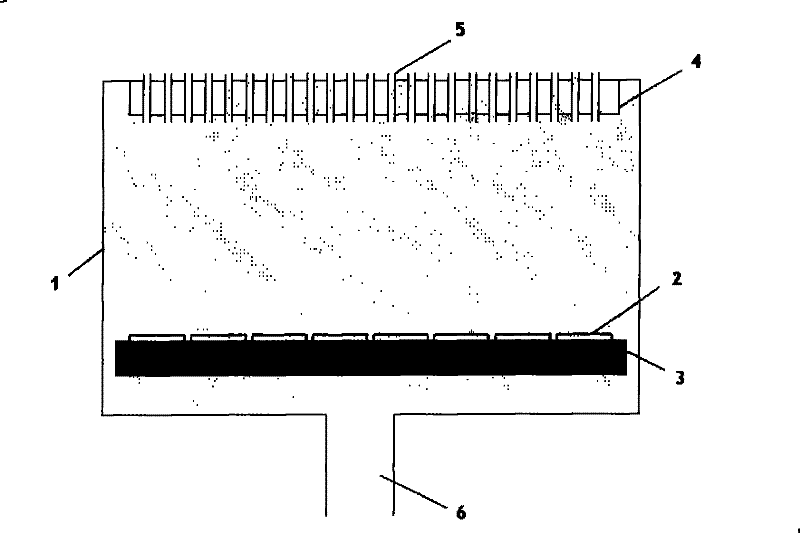

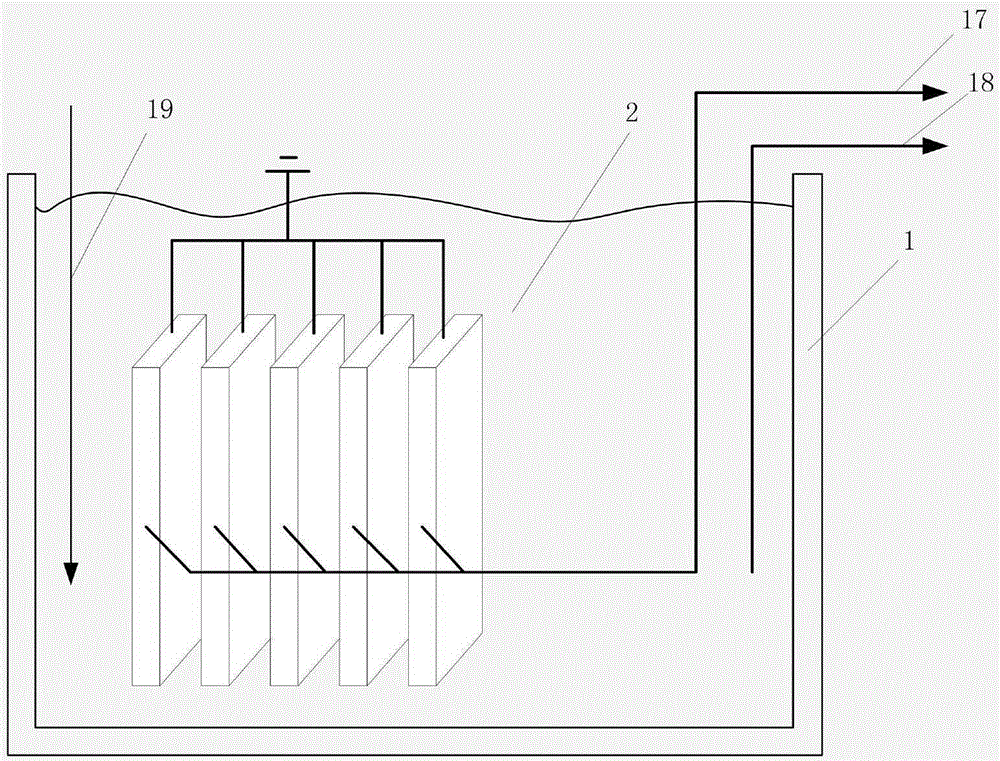

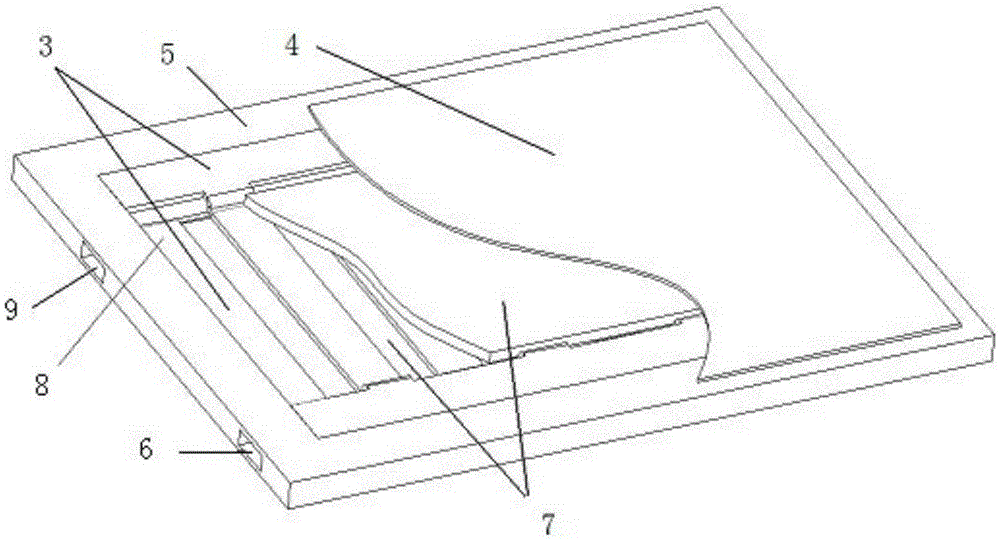

Dielectrophoresis flat osmotic membrane element

InactiveCN103463986AReduce or even eliminate pollutionReduce or even eliminate membrane cloggingElectrodialysisPolarization densityMembrane configuration

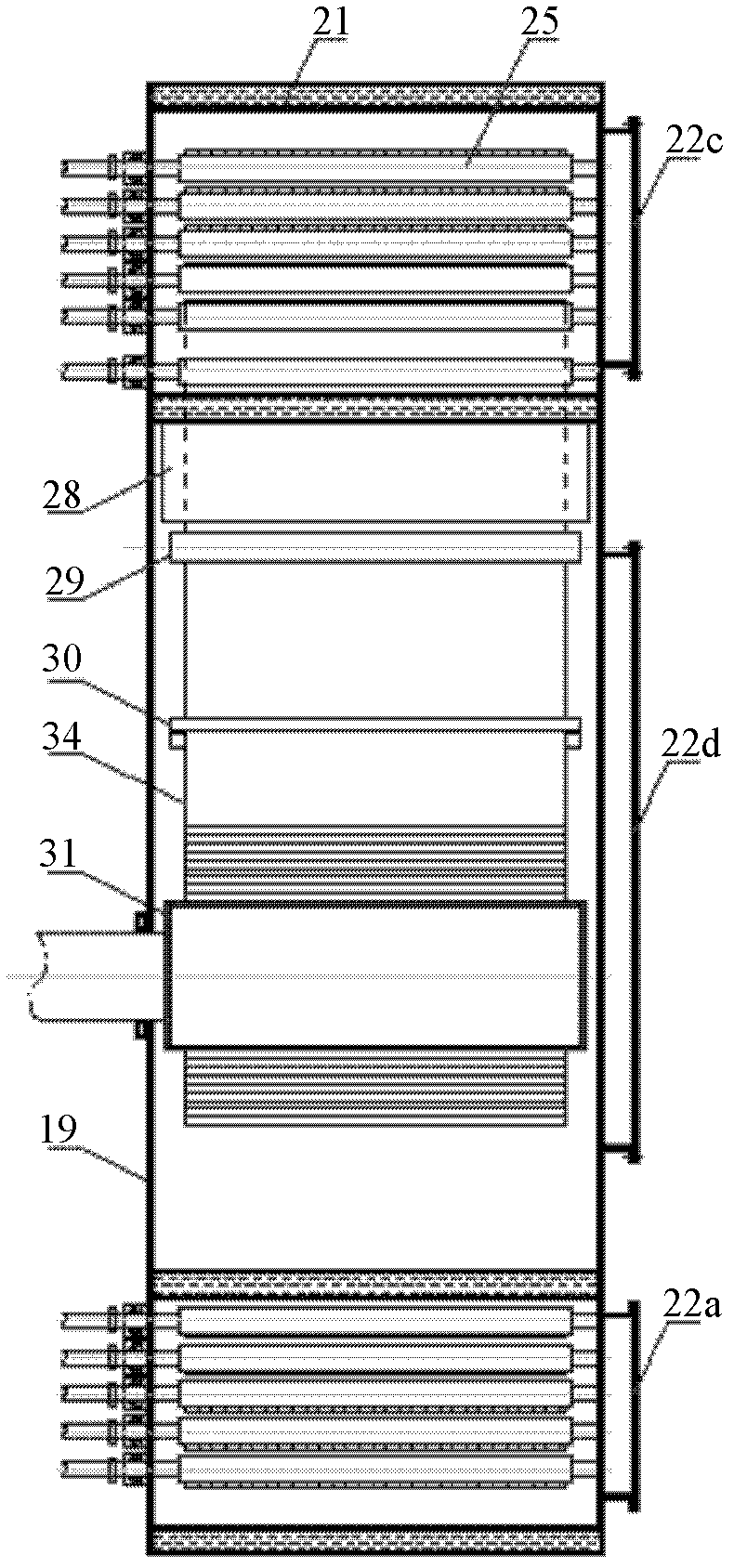

The invention relates to a dielectrophoresis flat osmotic membrane element, comprising a flat framework, electrodes and osmotic membranes, wherein the flat framework is made of ABS; the flat framework is internally embedded with electrodes that are horizontally distributed at intervals; the front and rear surfaces of the flat framework are provided with osmotic membranes through compression molding; a clean water opening and a wire outlet are formed in the flat framework; the clean water opening is communicated with a water channel inside the flat framework; the wire outlet is connected with the electrodes of the flat framework and used for leading out a wire to be connected with an external power source. By adopting the dielectrophoresis technology and utilizing the principle that dielectric polarization capabilities of solid particles and continuous phases on which the solid particles are suspended are different, the solid particles are pushed away from the electrodes or are adsorbed on the electrodes by the dielectrophoresis force, thus reducing or even eliminating the phenomena of membrane pollution and membrane blockage in the osmotic membrane process, prolonging the service life of the osmotic membrane, enhancing the transmission of the osmotic membrane and intensifying the osmotic membrane process.

Owner:INNER MONGOLIA TIANYI ENVIRONMENTAL TECH

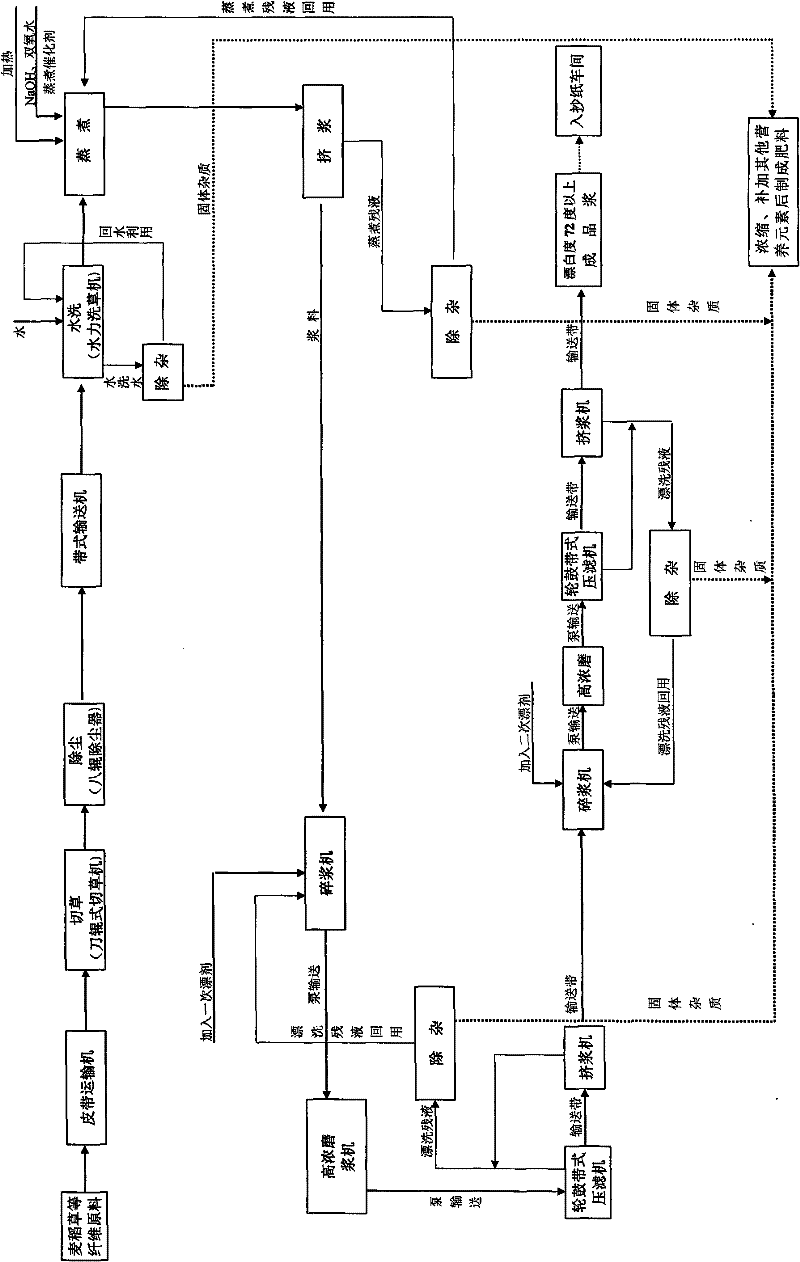

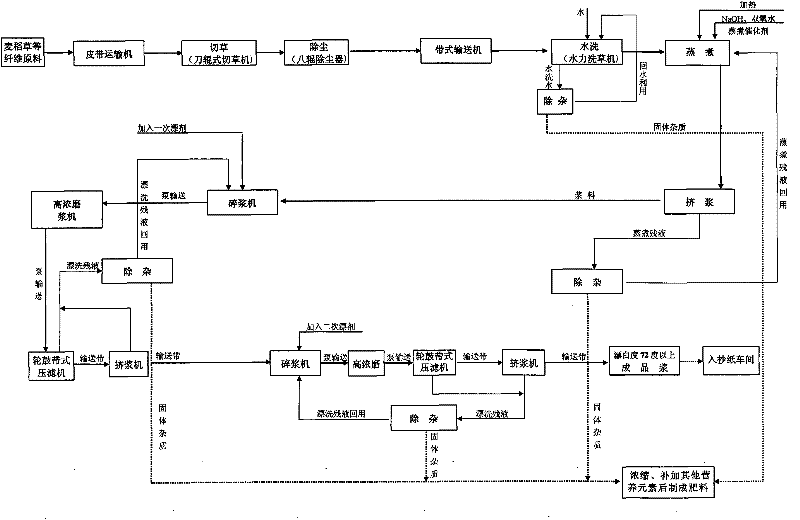

Alkali-hydrogen peroxide method-based cooking catalyst and clean pulping process

InactiveCN101823002ALower requirementHigh whitenessOrganic-compounds/hydrides/coordination-complexes catalystsChemical industryFiberPapermaking

The invention relates to an alkali-hydrogen peroxide method-based cooking catalyst and alkali-hydrogen peroxide method-based clean pulping process, which belong to the technical field of papermaking. The cooking catalyst mainly comprises the following raw materials in part by weight: 3 to 10 parts of chelant, 4 to 10 parts of magnesium sulfate, 7 to 15 parts of sodium silicate and 16 to 30 parts of urea; and the catalyst can lower the cooking temperature and pressure to enable that the cooking residual liquid keeps higher whiteness which brings convenience to cyclic utilization. The pulping process comprises the following step of: cooking the pretreated fiber raw materials by using alkali and hydrogen peroxide, wherein the cooking catalyst is added into the cooking liquor in cooking; the catalyst needed by each oven dry metric ton of pulp comprises 3 to 10 kg of the chelant, 4 to 10 kg of the magnesium sulfate, 7 to 15 kg of the sodium silicate and 16 to 30 kg of the urea. The cooking residual liquid obtained by the process has a yellowish white color, and can be returned to the cooking equipment for the next cooking after solid impurities are removed; and when the cooking residual liquid is circularly utilized, the rinsing cost of the pulp is not increased, and the cost is low in cyclic utilization, so the alkali-hydrogen peroxide method-based cooking catalyst and the alkali-hydrogen peroxide method-based clean pulping process are favorable for saving energy and reducing emission.

Owner:金永安 +2

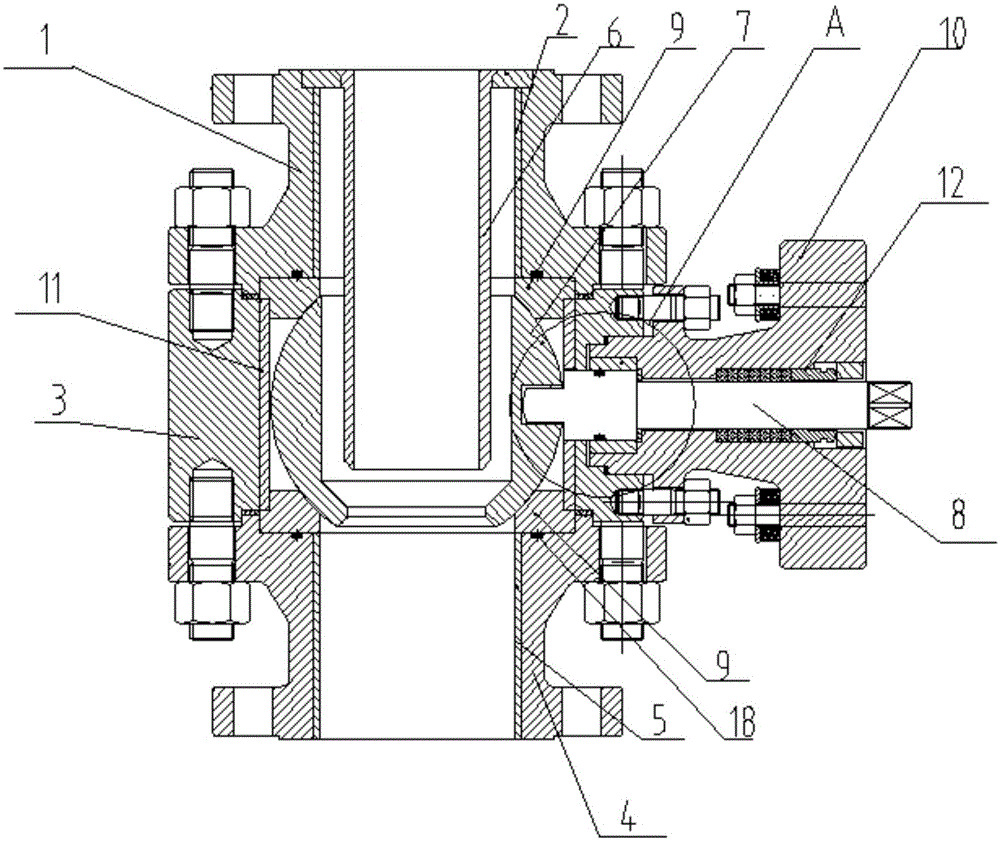

Floating type multi-phase cut-off repose angle valve

InactiveCN105114653AReduce or even eliminate pollutionQuality is not affectedPlug valvesGas phaseEngineering

The invention discloses a floating type multi-phase cut-off repose angle valve. The floating type multi-phase cut-off repose angle valve comprises a valve body. A valve element with a valve rod is arranged in the valve body in a rotating mode. Valve bases are arranged between the valve element and an upper flange and between the valve element and a lower flange respectively. The valve element comprises a feed port, a discharge port and a side opening communicated with the feed port. The width of the side opening is larger than the diameter of an inlet guide pipe. When the discharge port of the valve element is parallel to the outlet of the inlet guide pipe, the floating type multi-phase cut-off repose angle valve is in the opened state, powder enters the valve element through the inlet guide pipe and then flows to a lower flange liner tube to be discharged, and powder conveying is achieved. When the repose angle valve needs to be closed so as to cut off powder conveying, the valve rod is rotated, the valve element is made to rotate by 90 degrees, the discharge port of the valve element is converted to being relatively perpendicular to the outlet of an inlet liner tube from being parallel to the outlet of the inlet liner tube, the gas phase is cut off firstly through the valve bases and the spherical valve element, and dust raising is prevented. The powder is accumulated on the inner wall of the valve element when falling down from the inlet guide pipe; due to the unique repose angle characteristic of the powder, the powder is unceasingly accumulated till the outlet of the inlet guide pipe is closed through the powder in an inner cavity of the spherical valve element, and the powder is cut off.

Owner:WUXI HAILI AUTOMATIC CONTROL ENG CO LTD

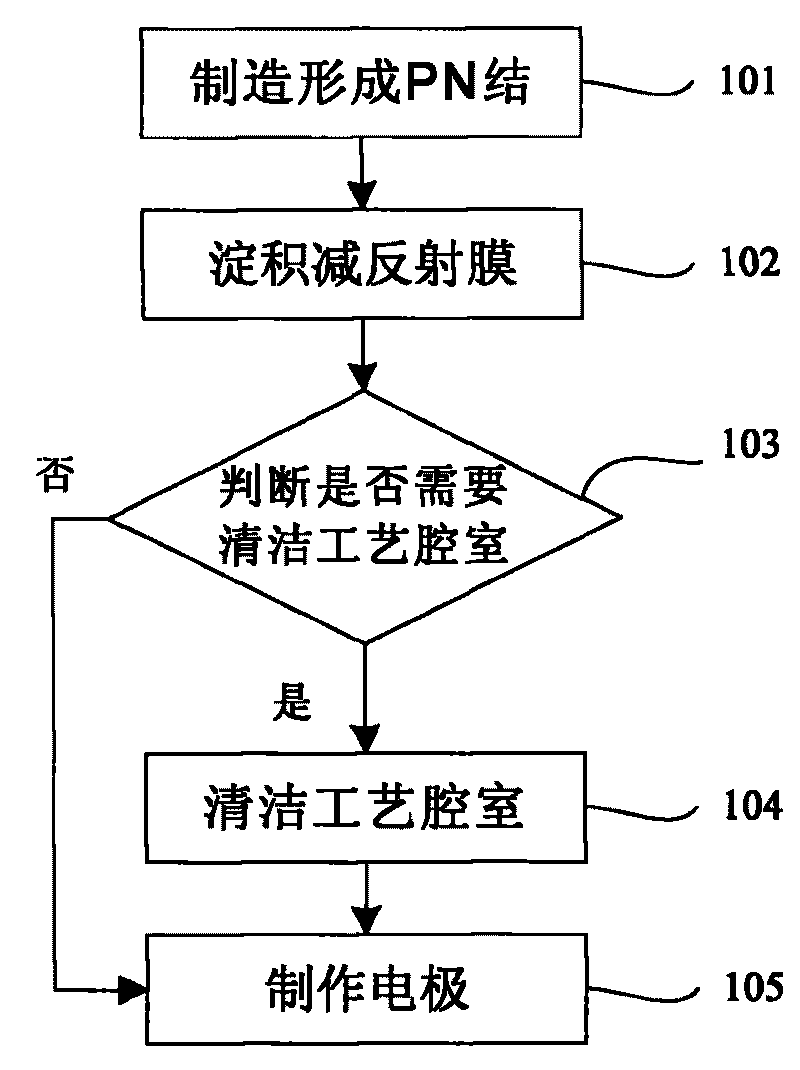

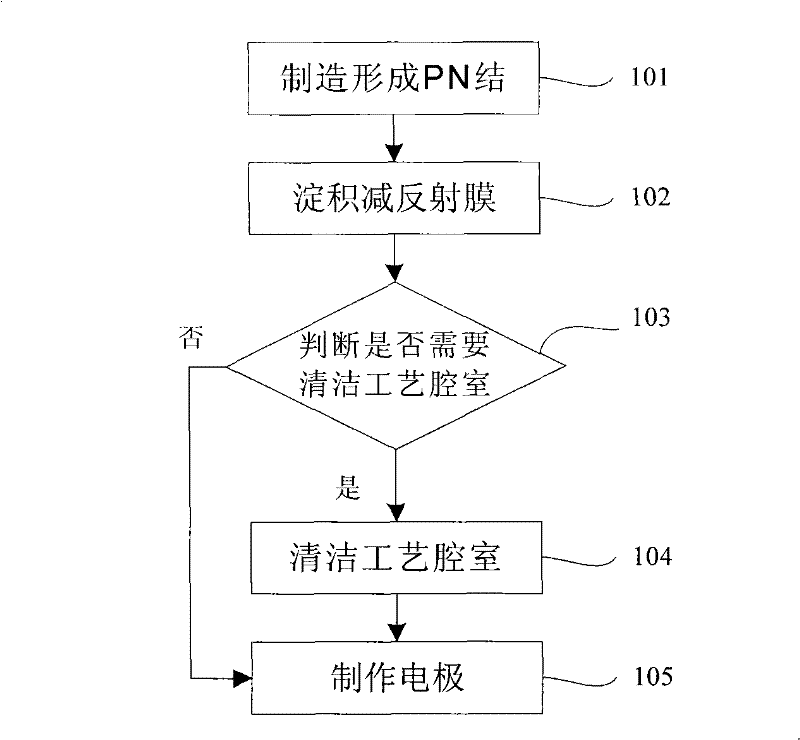

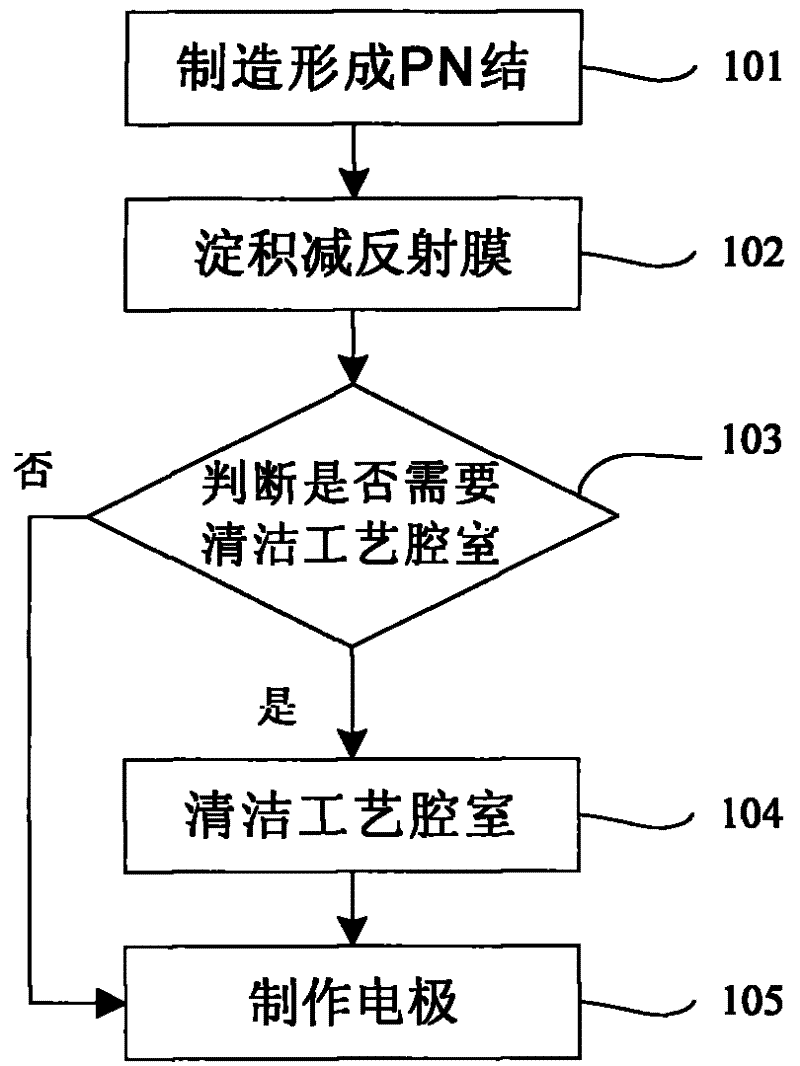

Method and equipment for manufacturing solar battery

ActiveCN101752457AImprove performanceQuality improvementFinal product manufactureChemical vapor deposition coatingElectrical batteryComputer module

The invention relates to a method for manufacturing a solar battery, comprising the following steps: (101), manufacturing and forming a PN junction; (102), depositing an anti-reflection film; (103), judging whether a technological chamber is needed to be cleaned or not, if so, performing the step (104), and otherwise, performing the step (105); (104), cleaning the technological chamber; and (105), manufacturing electrodes. In addition, the invention also relates to equipment for manufacturing the solar battery, comprising the technological chamber, an air intake device, an evacuating device, a PN junction forming module, a deposition module, a control module, a chamber cleaning module and an electrode manufacturing module. By adopting the method and the equipment for manufacturing the solar battery, the technological vacuum chamber is cleaned when judged to need cleaning without machine halt. Therefore, the method and the equipment for manufacturing the solar battery can effectively reduce and even eliminate the condition that attachments on the inner wall of the chamber fall off to cause pollution for a silicon wafer and can improve the production efficiency of the equipment.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Sustained and controlled release compound fertilizer and its preparation method

ActiveCN102731222AIncrease profitReduce or even eliminate wasteFertilizer mixturesAgricultural engineeringNutrient absorption

The invention discloses a sustained and controlled release compound fertilizer and its preparation method. The compound fertilizer is a particulate fertilizer, the particulate fertilizer contains various nutrients, and surfaces of solid particles of each nutrient are coated with sustained and controlled release gummy films. The preparation method comprises the following steps: 1, respectively preparing the various nutrients: (1) crushing base raw materials of a single nutrient, (2) adding the crushed base raw materials to a high speed mixer, starting the high speed mixer, and adding the gummy material having a weight being 2-8% of the total weight of the base raw materials to the high speed mixer, fully stirring and mixing the base raw materials of the particles and the gummy material to form the gummy films on the surfaces of the base raw materials of the particles and make the nutrient have a microcapsule shape, and (3), respectively preparing other nutrients according to step (1) and step (2); and 2, preparing the sustained and controlled release compound fertilizer: sending the various microcapsule-shaped nutrients to a granulator, and granulating to mutually mix the various microcapsule-shaped nutrients and form the sustained and controlled release particulate fertilizer. According to the invention, the agreement of the nutrient release rate of the fertilizer and the plant nutrient absorption rate is improved, and the utilization rate is high.

Owner:SICHUAN MEIFENG CHEM IND

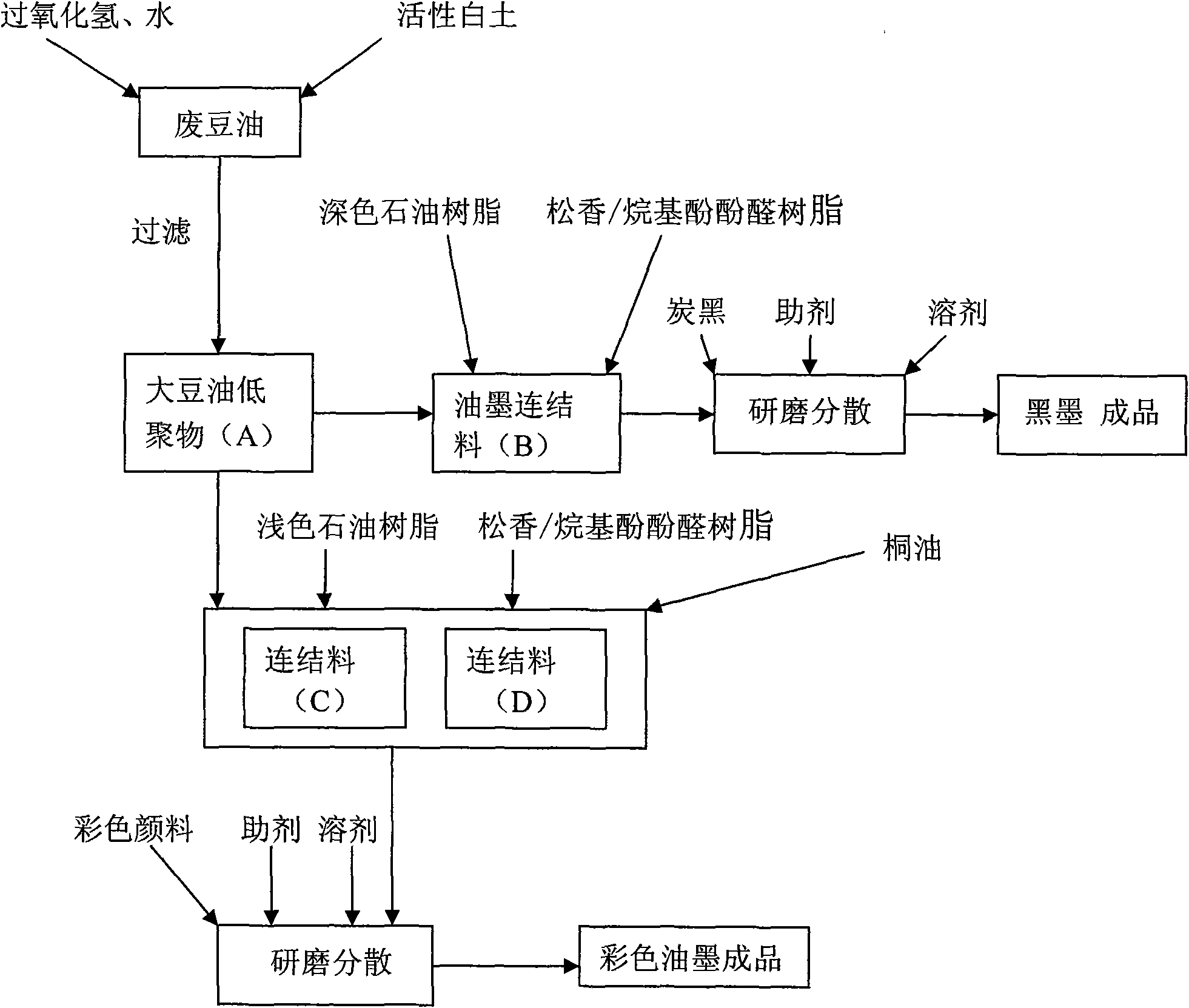

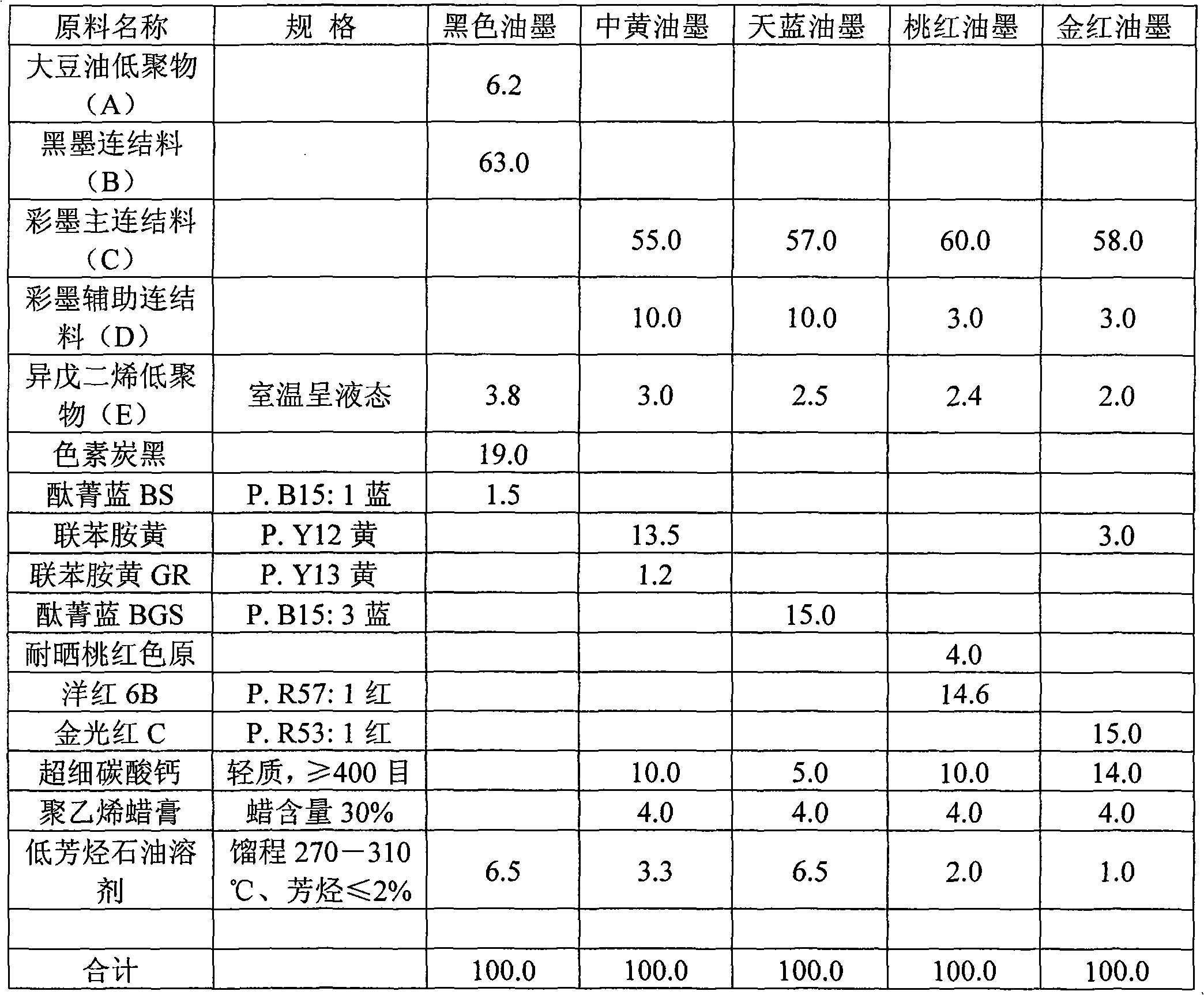

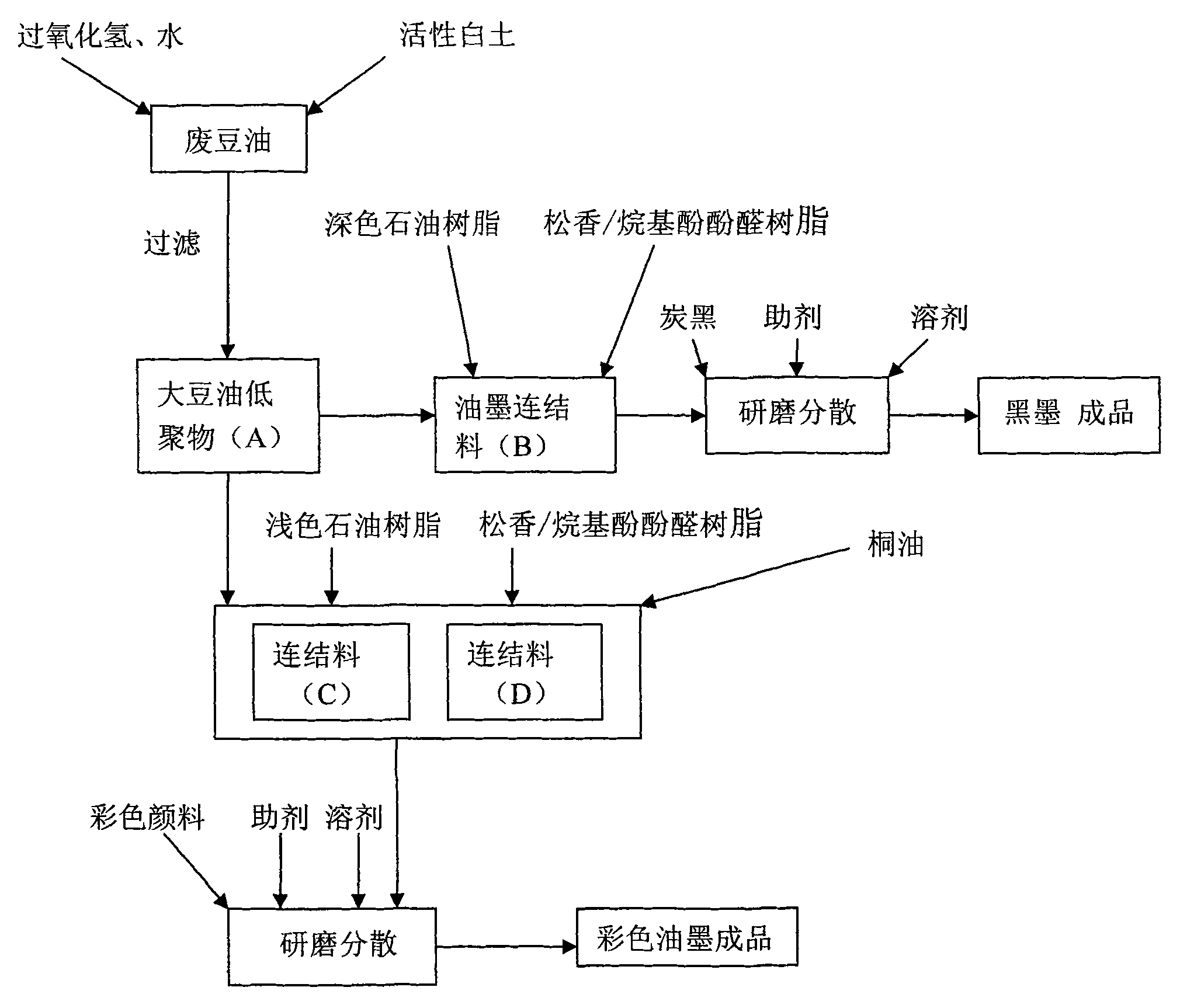

Soybean oil oligomer and preparation method thereof

InactiveCN102010657ASignificant technological progressReduce or even eliminate pollutionDrying-oil oxidationDrying-oils from natural sourcesOligomerWastewater

The invention relates to a soybean oil oligomer and a preparation method thereof. The soybean oil oligomer is prepared from the following raw materials in percentage by weight: 90.9 percent of waste food processing oil, 4.1 percent of water, 1.4 percent of hydrogen peroxide solution and 3.6 percent of activated carclazyte. The preparation method comprises the following steps of: filtering, floating, and heating to 50 DEG C in a reaction kettle for reaction; then, spraying with an aqueous hydrogen peroxide solution, carrying out a thermal reaction, standing still, delaminating, discharging impurity wastewater at the bottom and increasing the temperature to 120-130 DEG C; adding the activated carclazyte, keeping the temperature, stirring, sampling and comparing colors until the temperature is not reduced any more; and stopping temperature retaining and filtering to obtain the soybean oil oligomer when the temperature is reduced to a temperature below 70 DEG C. The invention adopting the advanced hydration-oxidation method and the activated carclazyte absorption method has simple and convenient process operation and obvious floating and decoloring effects. The refined soybean oil oligomer obtained by using the method has high purity and is particularly suitable for producing the link stuff of various kinds of news ink.

Owner:鹤壁百运佳大豆油墨科技有限公司

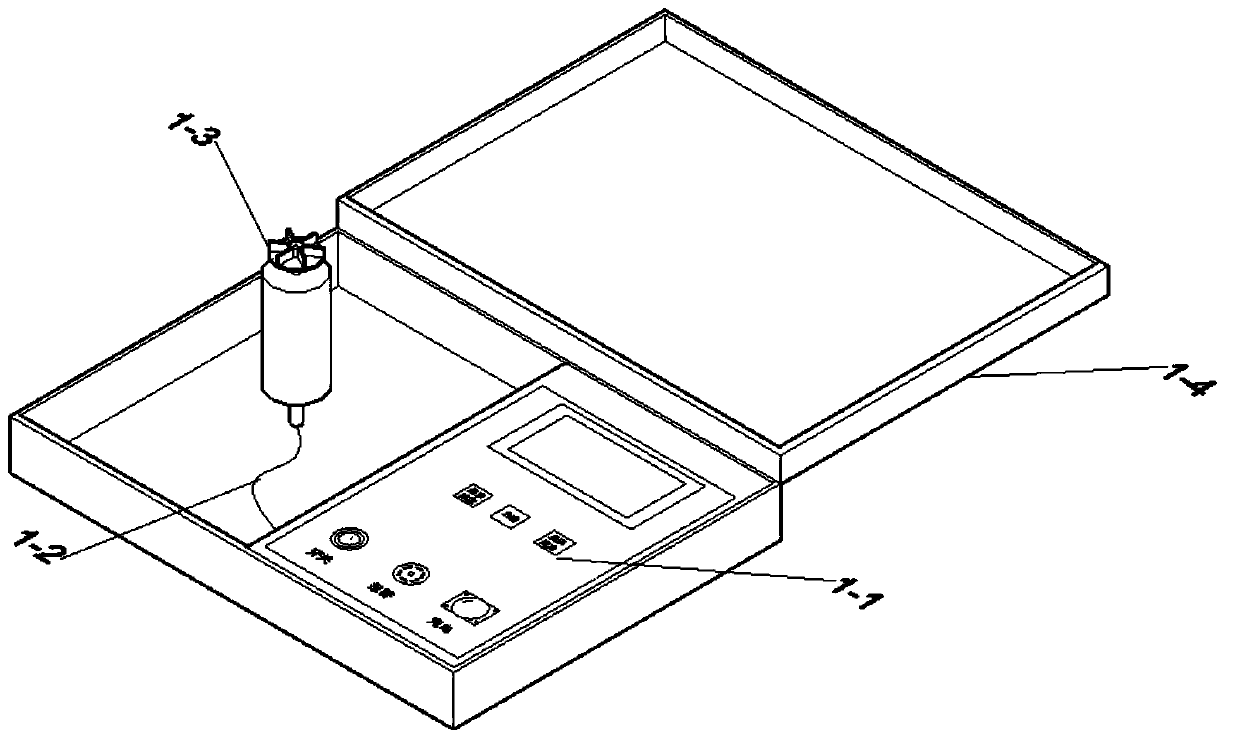

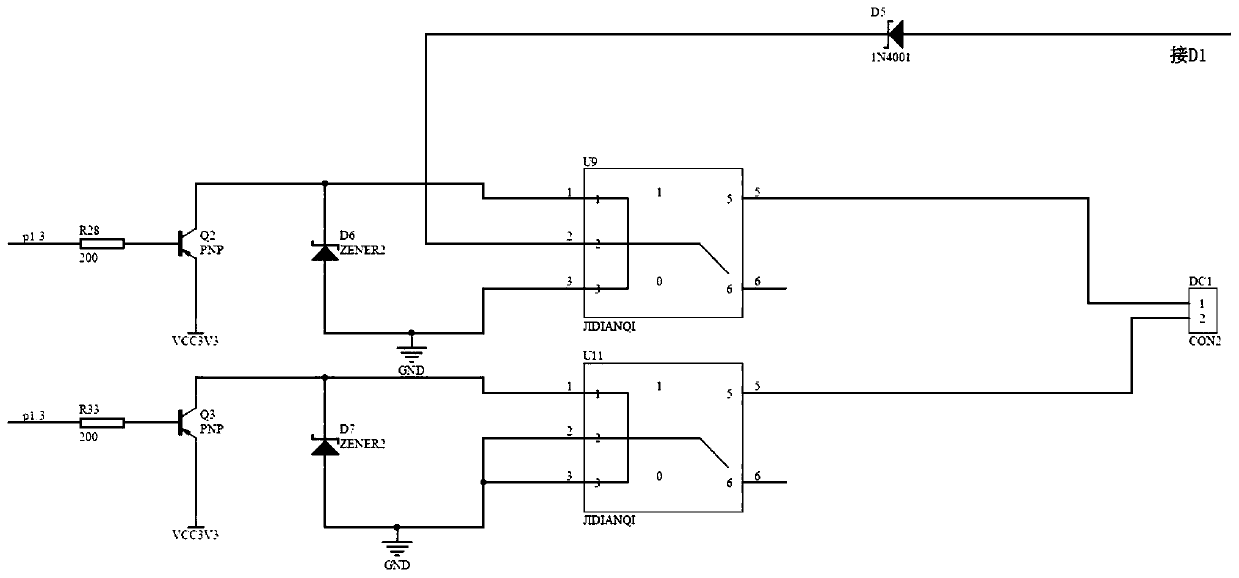

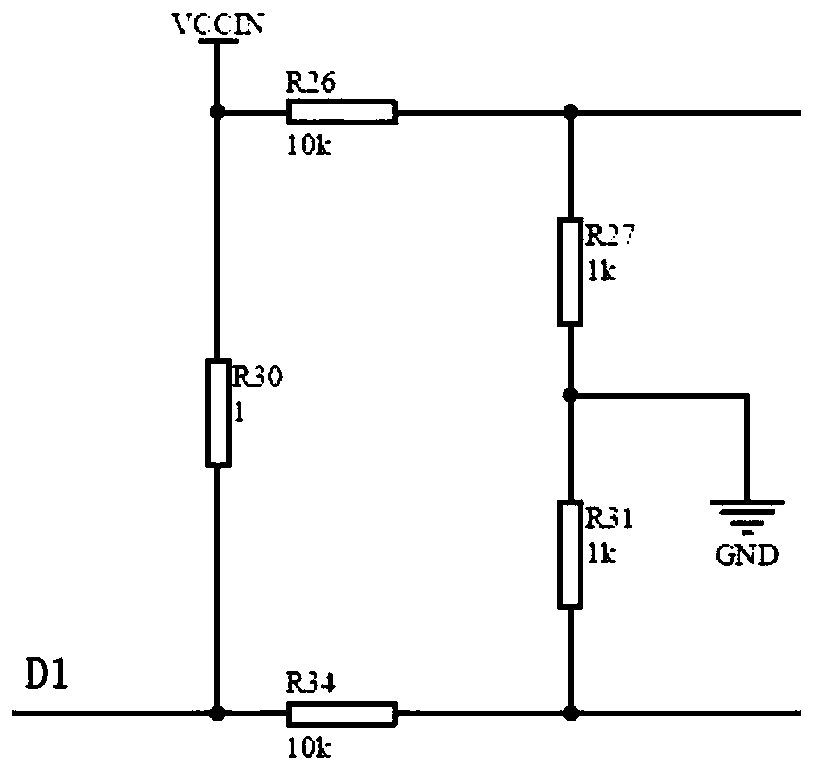

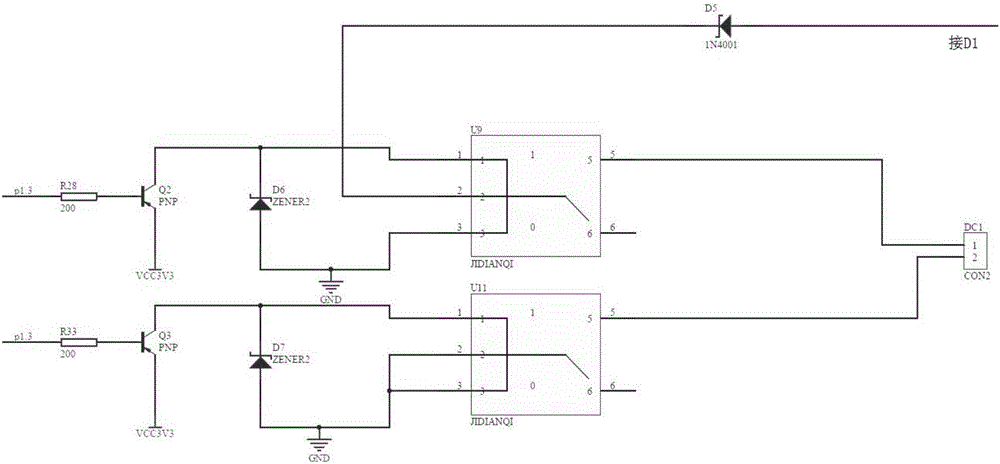

Concealed concrete filling elevation controller and operating method thereof

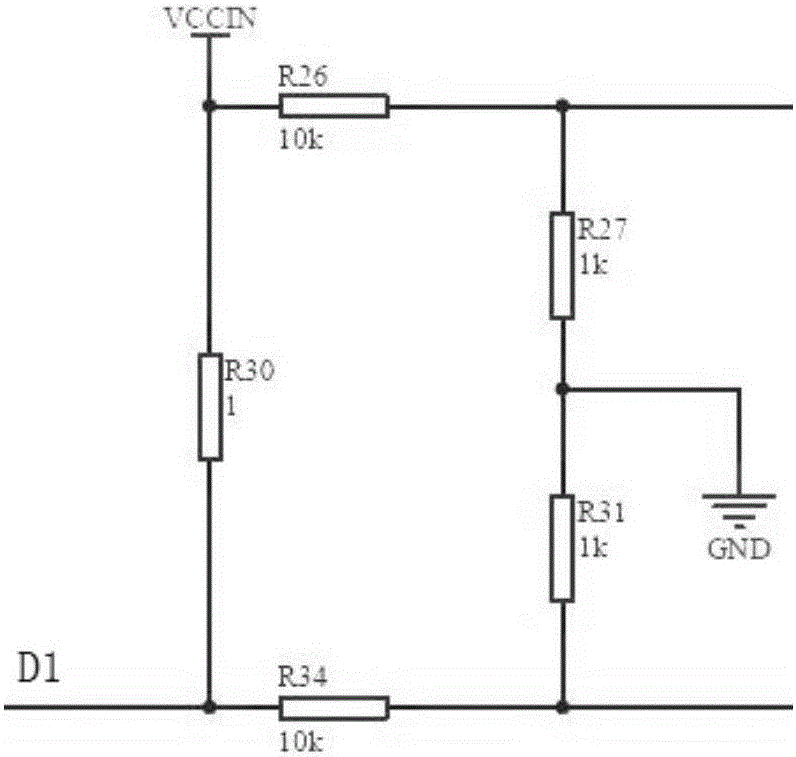

InactiveCN110409522ASimple structureEasy to operateFoundation testingElectrical/magnetic thickness measurementsSignal processing circuitsElectrical current

Owner:山东启尔贸易有限公司

Water floating body

The invention discloses a water floating body. The water floating body comprises at least one hoisting floating tank on which a wood board layer is paved; a plurality of heavy structures for reinforcing are arranged in the hoisting floating tank; or the floating body comprises a plurality of hoisting floating tanks which are closely interconnected through an external structure; the wood board layers are paved on the hoisting floating tanks. The water floating body has the beneficial effects that the structure is simple, the cost is small, the applicable scope of water area is wide, and inland river, internal lake, coastal confined water area, coastal hidden water area, water area around coastal island and coastal water area apply.

Owner:黄继昌

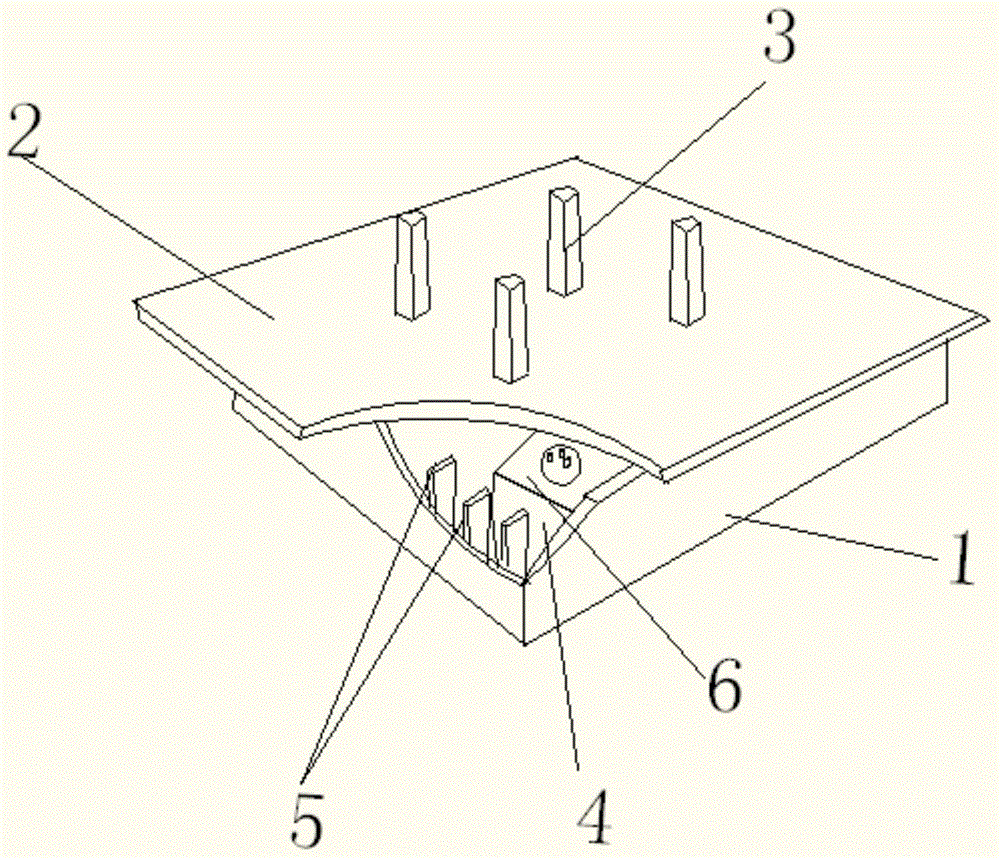

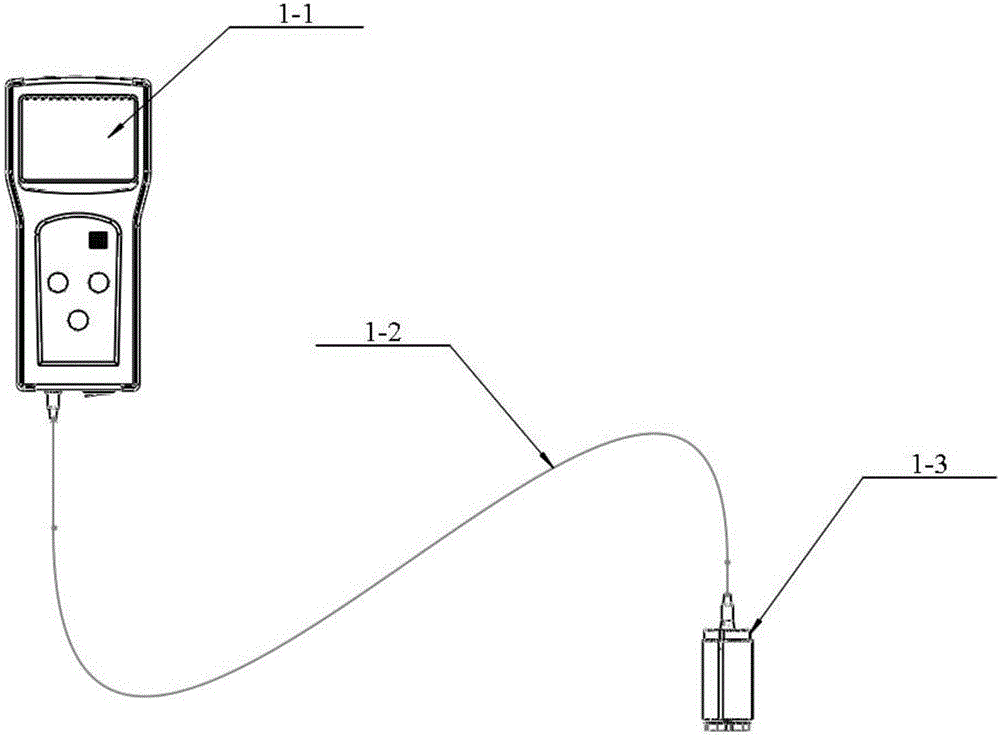

Handheld underwater grouting pile top-surface elevation control early-warning device and method

ActiveCN105928489ASimple structureEasy to operateHeight/levelling measurementPower flowSignal processing circuits

The invention discloses a handheld underwater grouting pile top-surface elevation control early-warning device and method. The handheld underwater grouting pile top-surface elevation control early-warning device comprises a handheld alarm, a waterproof lead and an underwater closed probe. The handheld alarm is provided with a main controller, a power supply, a signal processing circuit and an alarm circuit inside, wherein the power supply, the signal processing circuit and the alarm circuit are connected with the main controller respectively. A motor is arranged in the underwater closed probe. When concrete is grouted, coarse aggregate rises to the designed elevation, the motor inside the underwater closed probe rotates in a resistant manner, and shoot-up current signals generated by the resistant rotation are connected to the handheld alarm through the waterproof lead to generate alarm signals. The handheld underwater grouting pile top-surface elevation control has the advantages of simple structure and convenience in operation and can be accepted by on-site constructors. Through test on the construction site, pile top elevation of the underwater grouting pile can be accurately controlled, within 5 cm, and control accuracy is remarkably improved as compared with that of conventional pile detection methods.

Owner:SHANDONG UNIV

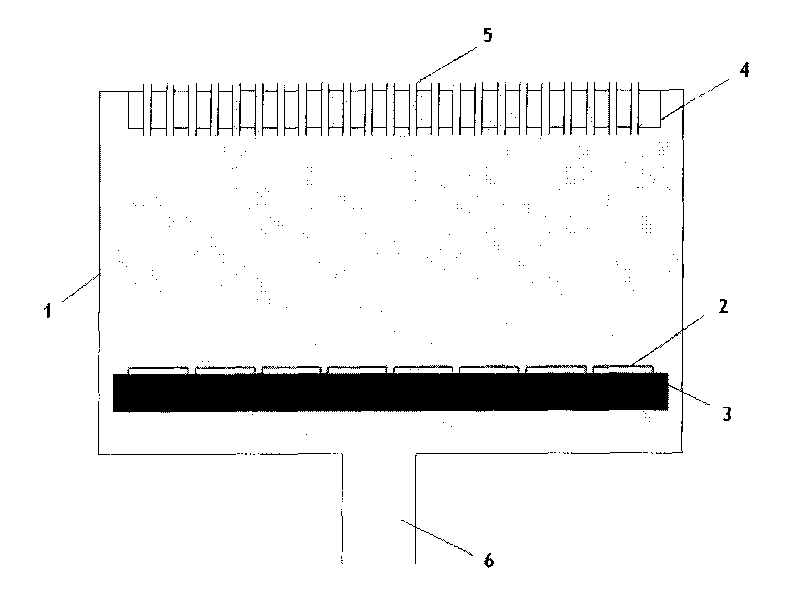

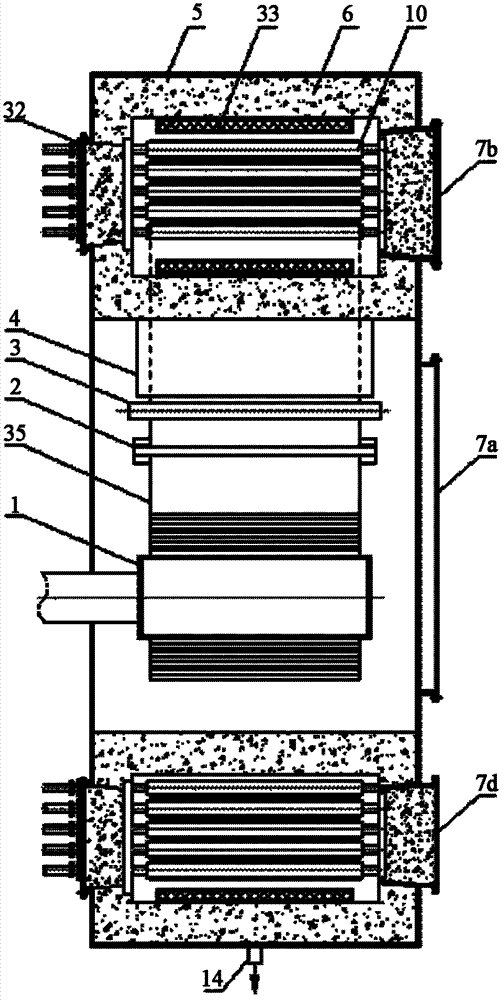

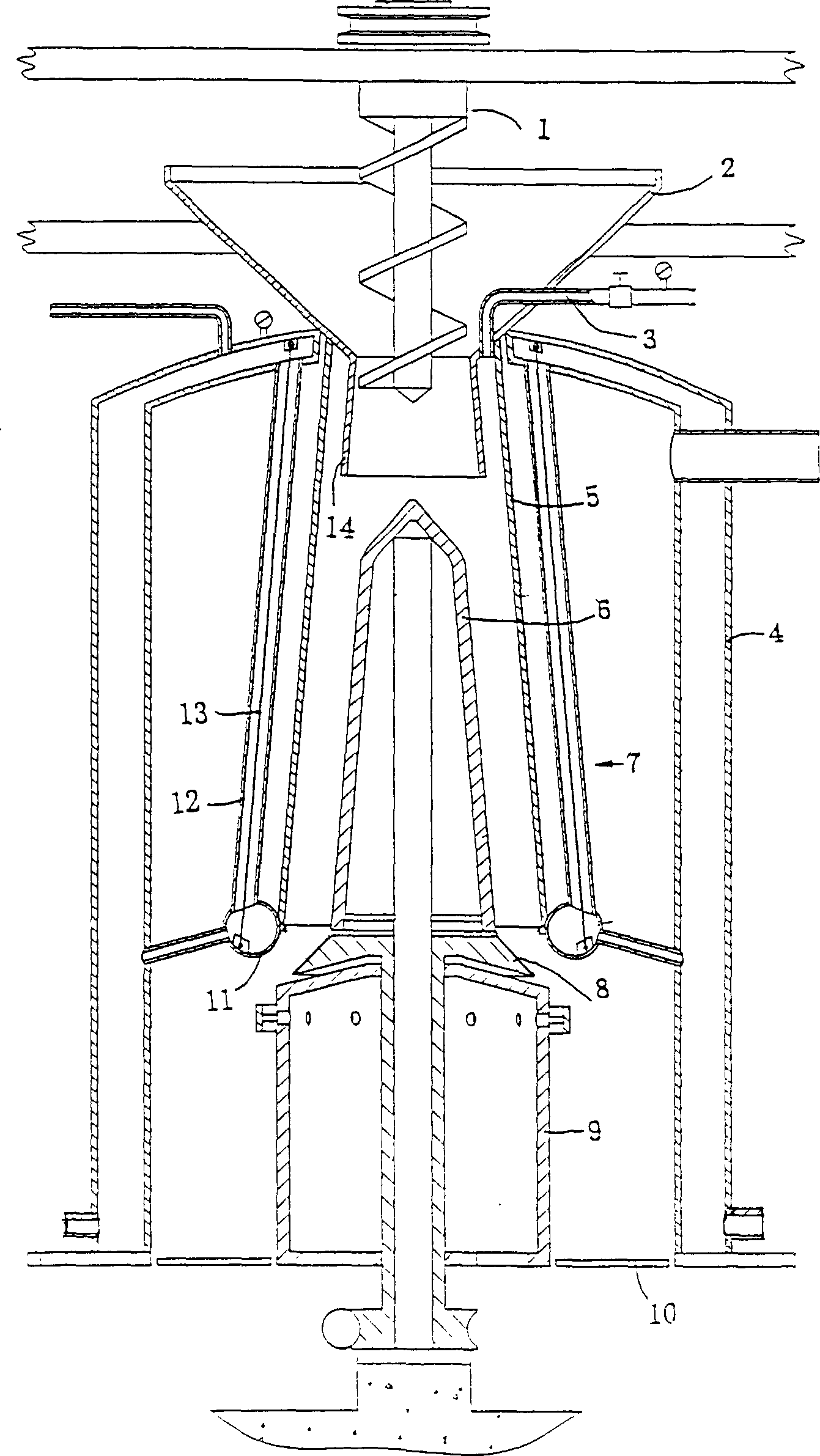

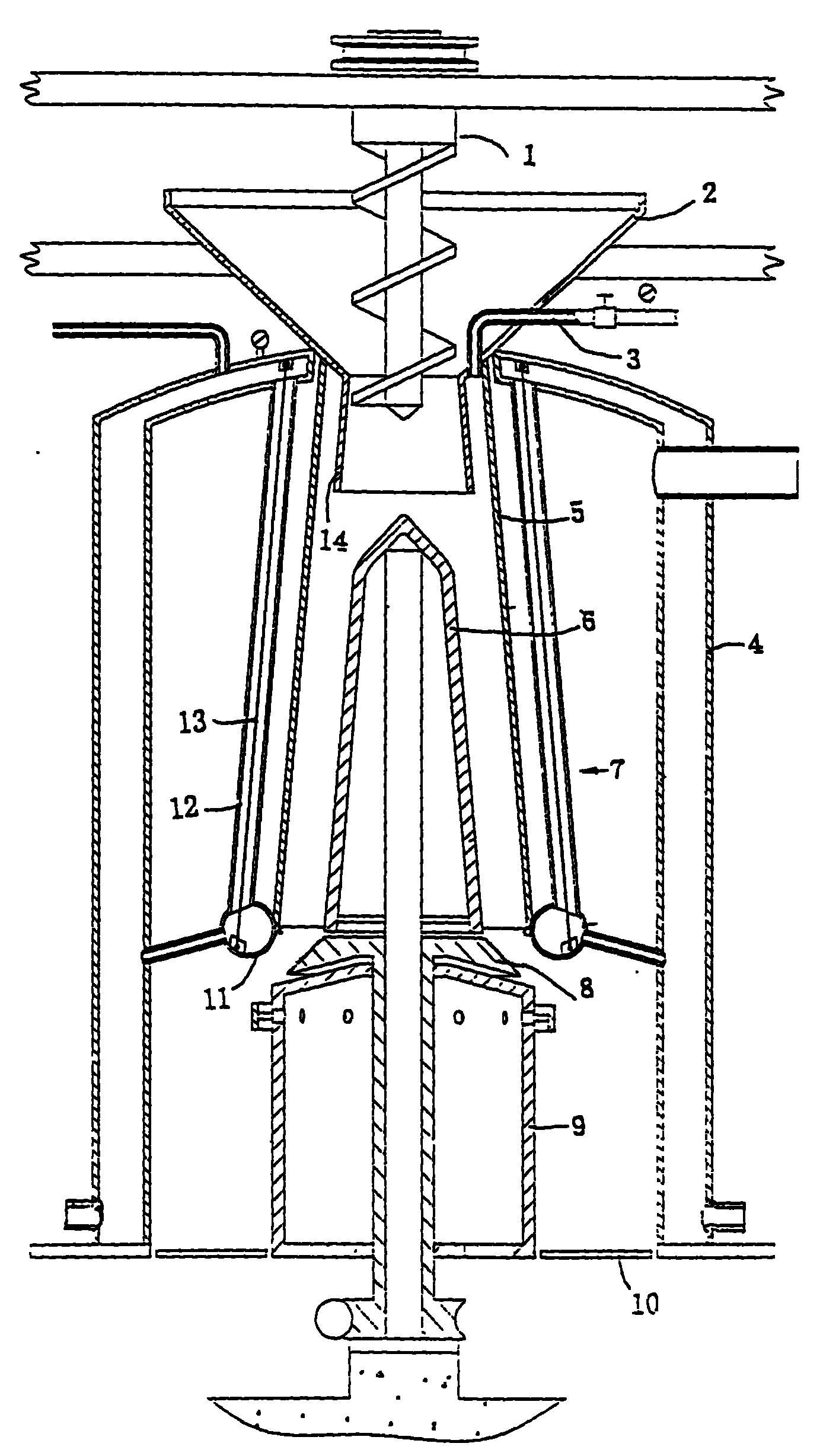

Continuous reduction annealing furnace for sheet metal strips

InactiveCN102586577AIncrease productivitySmall footprintFurnace typesHeat treatment furnacesMetal stripsInsulation layer

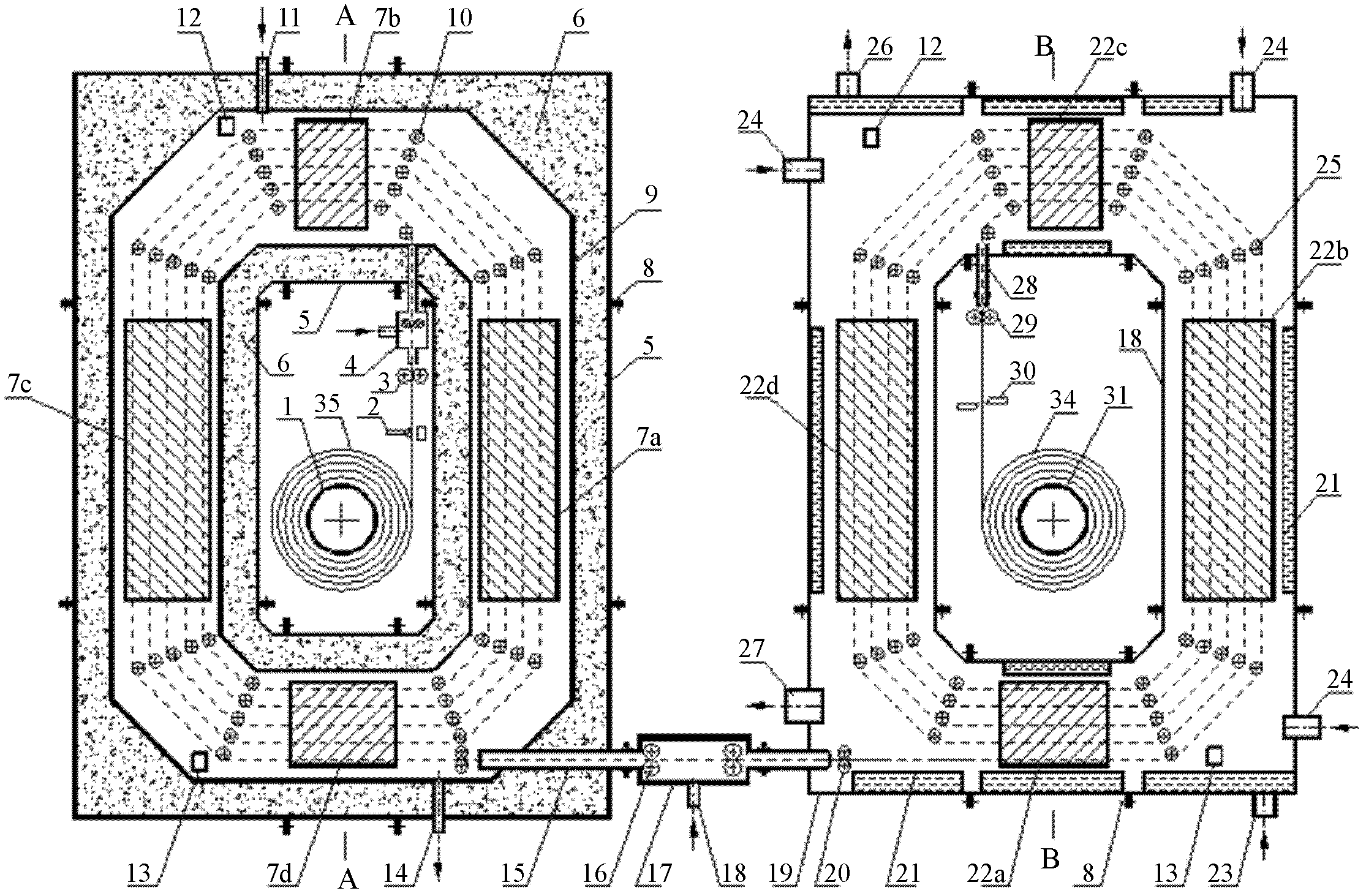

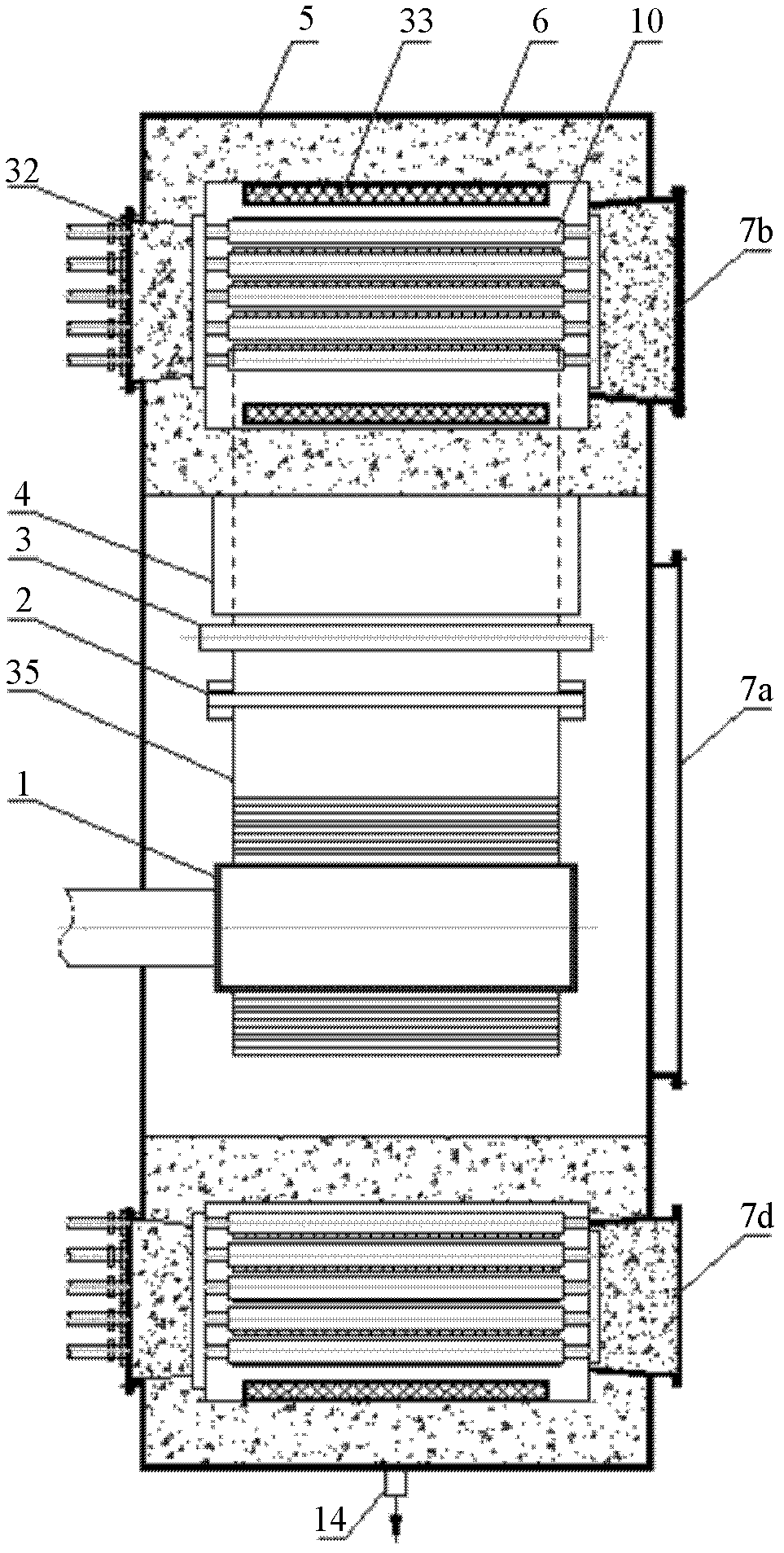

The invention discloses a reduction annealing furnace for continuous reduction and heat treatment of sheet metal strips. By utilizing the reduction annealing furnace, reduction descaling of hot-rolled strips or annealing treatment of cold-rolled strips can be continuously performed in a high-efficient, low-cost and high-quality manner. The reduction annealing furnace comprises a heating reductionsection furnace body, an intermediate transition section channel and a cooling section furnace body, wherein the heating reduction section furnace body comprises an inner furnace shell, an outer furnace shell and an intermediate heat insulation layer, a furnace chamber which is of a hollow square-shaped structure is formed by the furnace shells and the intermediate heat insulation layer, the strips are introduced into the furnace chamber after being opened by an uncoiler at the center of the furnace body, revolved for a plurality of circles through the guide of a guide roller table in the furnace chamber, then heated, reduced or annealed and then led out of the furnace body, and further enter into the cooling section furnace body via the intermediate transition channel, the cooling section furnace body is of a hollow square-shaped cooling chamber constituted by the multiple sections of housings, and the strips are revolved for the plurality of the circles in the cooling chamber, cooled in a non-oxidation manner and coiled into strip coils by a coiling machine. The reduction annealing furnace disclosed by the invention has the advantages of low equipment investment, small floor area, low production cost and good product quality.

Owner:UNIV OF SCI & TECH LIAONING

High-efficiency and pollution-free waste incineration power generation environmental protection supporting device and its application process

ActiveCN103900090BReduce or even eliminate pollutionIncrease power generationCombination devicesMultistage water/sewage treatmentSlagEmission standard

Owner:深圳市宇力科技有限公司

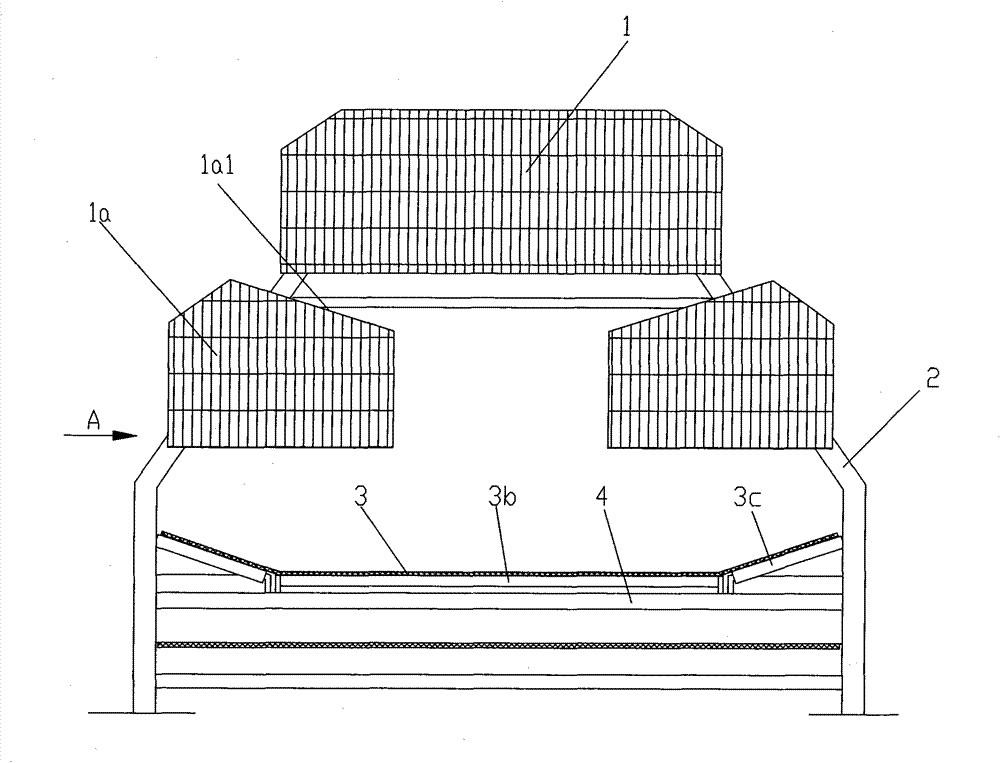

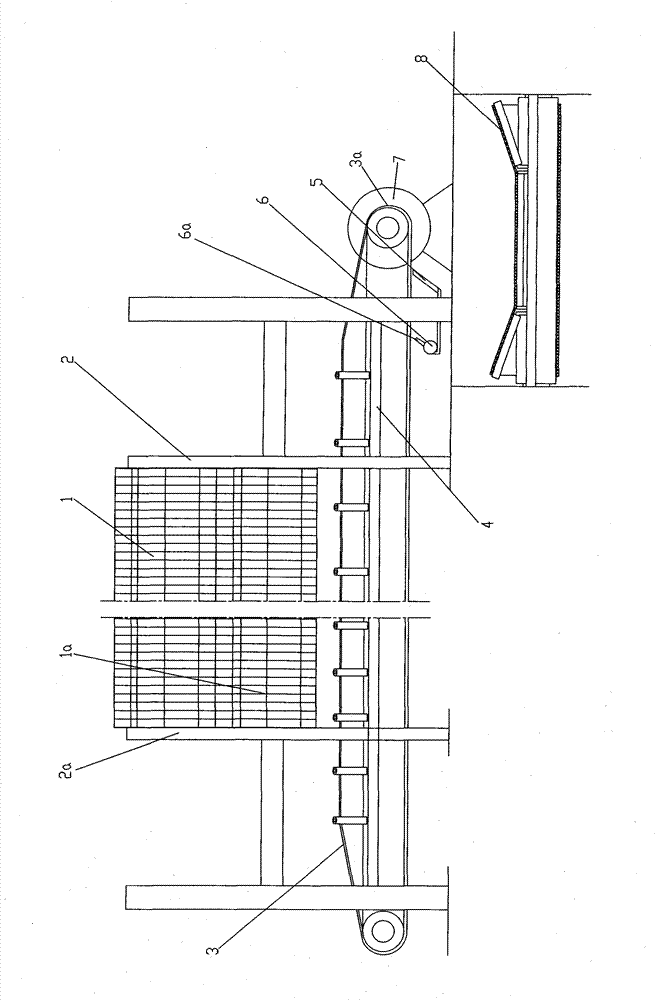

Artificial rabbit-breeding environment-friendly feeding facility

InactiveCN101933463BEfficient removalReduce high-intensity laborAnimal housingNormal growthHigh intensity

The invention discloses an artificial rabbit-breeding environment-friendly feeding facility, comprising a rabbit cage and an excrement-removing device, wherein the excrement-removing device comprises an excrement-removing conveyor belt and an actuating device for the excrement-removing device; and the rabbit cage is longitudinally arranged on the upper part of the excrement-removing conveyor belt. The invention adopts a structure which is characterized in that the excrement-removing conveyor belt is arranged on the lower part of the rabbit cage, so that the generated excrement can be removed timely and efficiently in accordance with the excrement generation condition, thus realizing the mechanical excrement-removing function, reducing high-strength labor of breeders resulting from removing the excrement, decreasing and even completely eradicating the pollution to rabbit hutches and the ambient environment, providing good environment for the normal growth of the rabbits, and being beneficial to keeping the ambient environment and realizing environmental protection.

Owner:CHONGQING AXINGJI FOOD

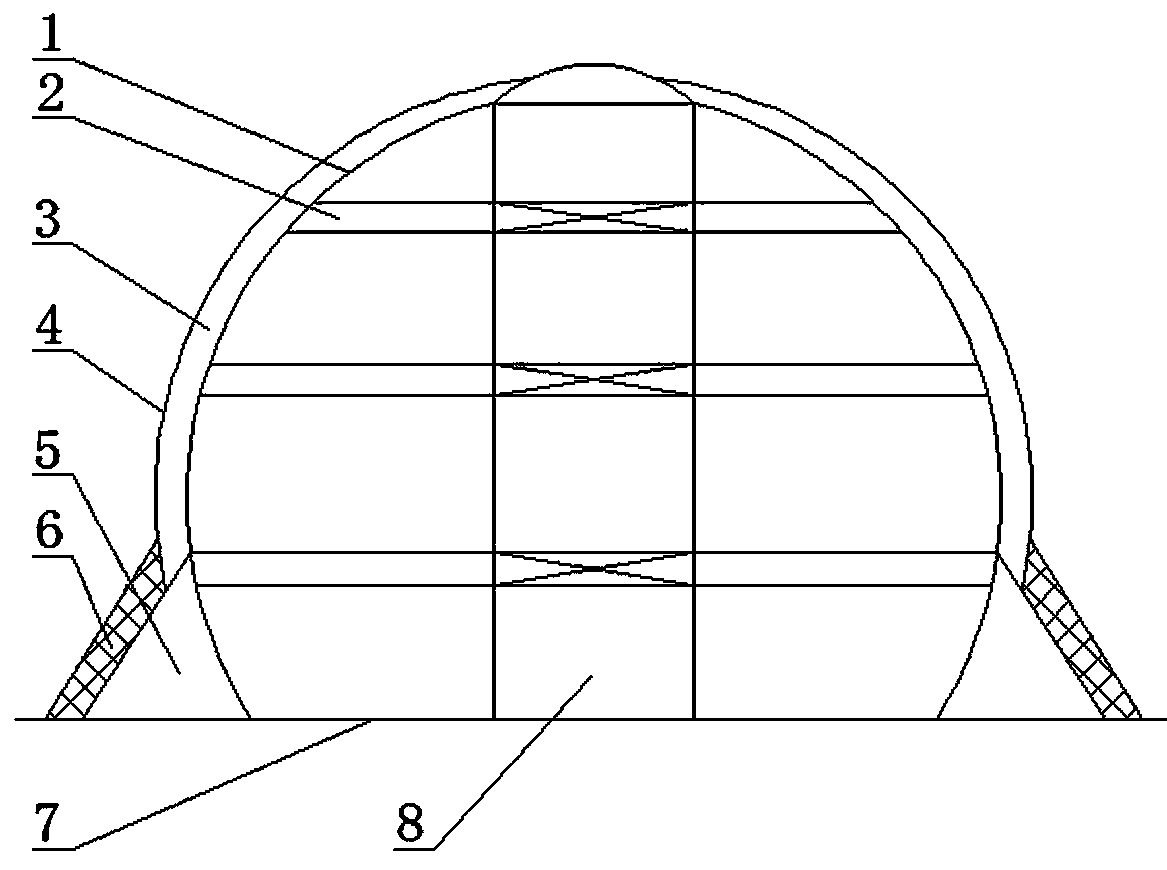

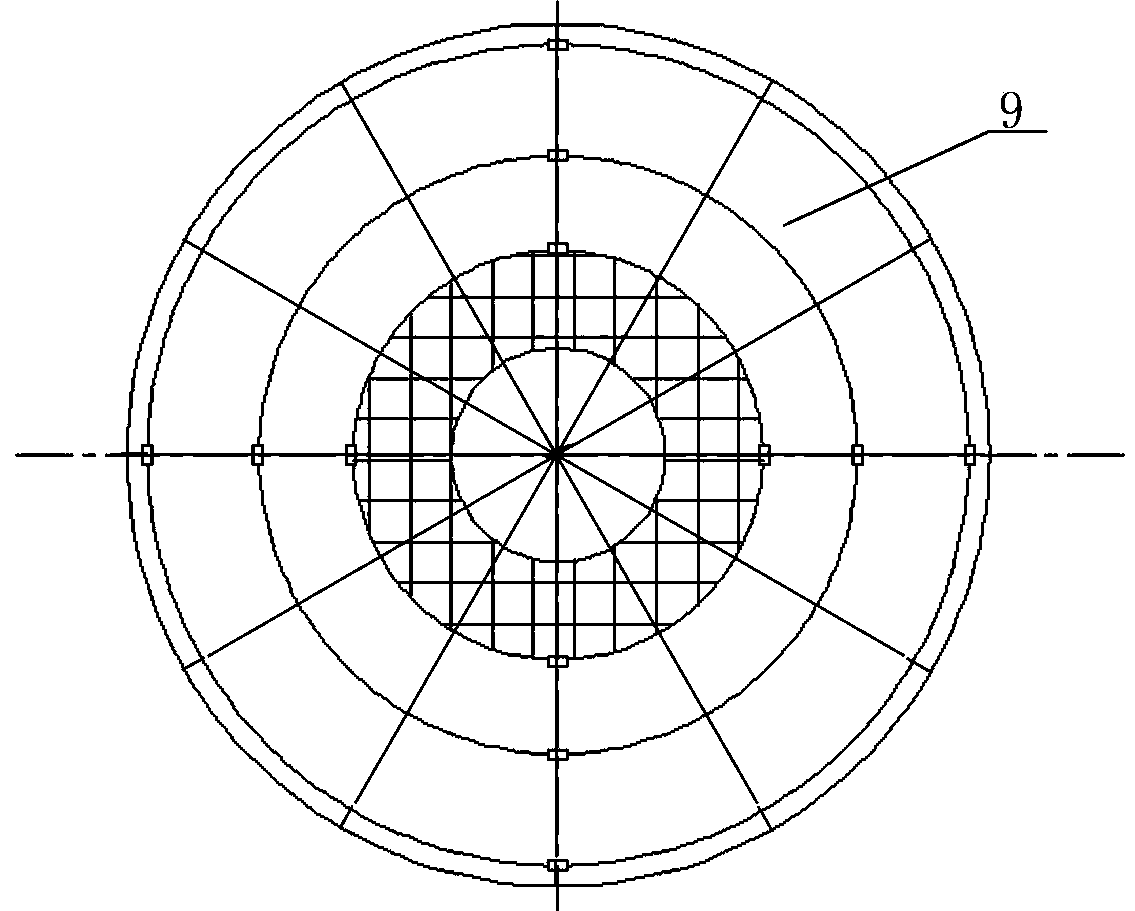

Solar heat storage greenhouse and building method thereof

ActiveCN103250598BReduce negative pressureSlip off quicklyClimate change adaptationGreenhouse cultivationSnowpackInsulation layer

A solar thermal storage greenhouse, which solves the problems of the existing spherical greenhouses such as narrow application range, small illumination area, low effective land use area, poor sealing, poor heat preservation, easy to be blown away by strong winds, easy to collapse with snow accumulation, and poor earthquake resistance. It includes a spherical frame with a light-transmitting thermal insulation layer outside the spherical frame. The technical points are: the spherical frame is composed of several polygonal frames, and a circle of phase-change thermal storage wall panels surrounds the bottom of the spherical frame. Phase-change thermal storage There is a living space between the wall panel and the spherical frame; the spherical frame is provided with inner and outer light-transmitting insulation layers, and a transparent foam heat storage layer is filled between the two light-transmitting insulation layers; the inner and outer light-transmitting insulation layers are made of transparent PVC material; the vertical direction in the spherical frame is divided into multi-layer planting areas by several mesh laminates, and the planting areas of each layer are planted without soil. It has the advantages of intelligent control, low construction cost and high land utilization rate.

Owner:刘立志 +1

Sustained and controlled release compound fertilizer and its preparation method

ActiveCN102731222BIncrease profitReduce or even eliminate wasteFertilizer mixturesEnvironmental engineeringNutrient absorption

A slow-controlled release compound fertilizer and a preparation method thereof. The compound fertilizer is a granular fertilizer, which contains various nutrients, and the surface of solid particles of each nutrient is covered with a layer of slow-controlled release colloidal film. Preparation method: 1) Prepare various nutrients separately: ①Crush the basic raw material of a single nutrient; ②Put the crushed basic raw material into the high-speed mixer and start the high-speed mixer; 2 to 8% colloidal material by weight, so that the basic raw materials of each particle and the colloidal material are fully stirred and mixed, and a colloidal film is formed on the surface of the basic raw material of each particle, which is in the shape of microcapsules; ③ According to steps ① and ②, prepare other types of Nutrients; 2) Preparation of slow and controlled release compound fertilizers: Send various microcapsule-shaped nutrients into a granulator for granulation, so that the nutrients in each microcapsule are mixed with each other to form slow and controlled release granular fertilizers. It improves the coincidence between the release rate of fertilizer nutrients and the absorption rate of plant nutrients, and has a high utilization rate.

Owner:SICHUAN MEIFENG CHEM IND

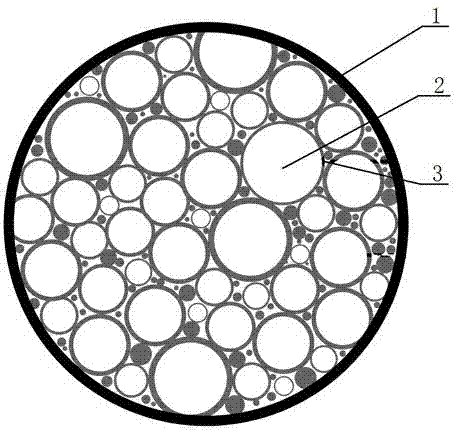

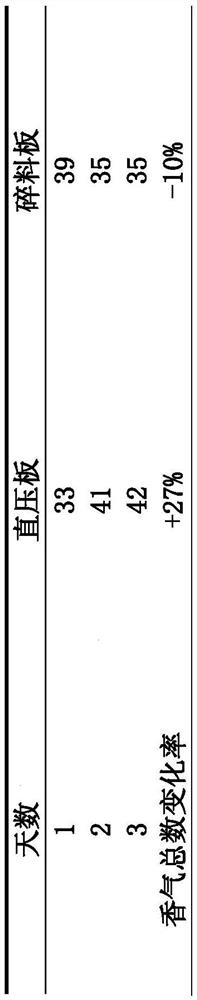

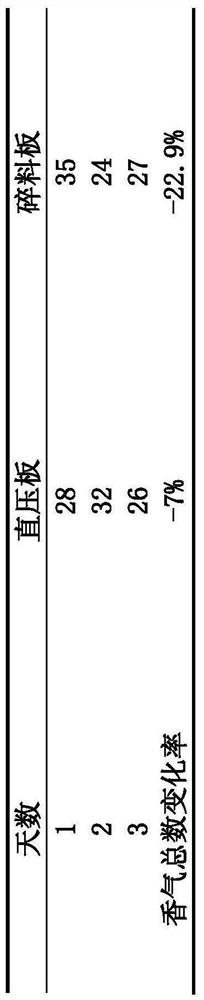

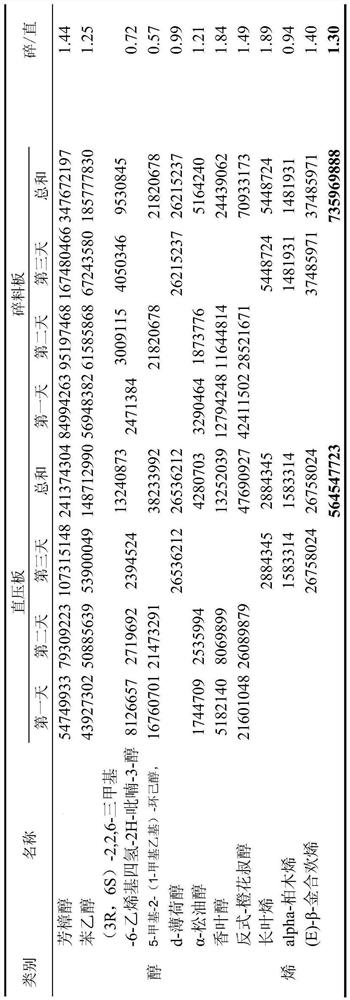

A preparation method of direct pressure slow-release tea fragrance environmental protection art board that releases and absorbs odor molecules

ActiveCN112248163BProcess exploration and improvementAvoid pollutionWood compressionWood treatment detailsAdhesiveBiology

The invention discloses a preparation method of a direct-pressure slow-release tea fragrance environmental protection art board that releases and absorbs odor molecules, comprising: 1) material selection: selecting tea tree wood materials as processing raw materials; 2) raw material processing: cutting tea tree wood materials or cut into processing units; 3) peeling: the processing unit in step 2) is subjected to peeling treatment, so that the bark content of the processing unit is controlled below 10%; 4) drying: the processing after step 3) is processed The unit is dried; 5) glue sizing: mix the processing unit after step 4) with the E0 grade environmental protection glue, and the mass ratio of the E0 grade environmental protection glue to the processing unit is 3-4%; 6) along the core: to step 5 ) process the processing unit after processing along the core so that it is controlled in the same arrangement direction; 7) billet assembly: pave and shape the processing unit after processing the core in step 6) and age to obtain a tea slab; 7) The pre-pressing treatment, hot-pressing treatment and cooling treatment are performed on the treated tea slab base to make a tea slab.

Owner:ZHEJIANG UNIV

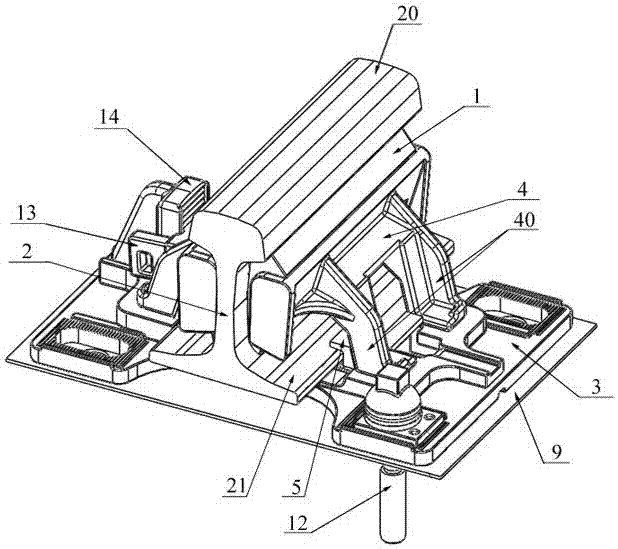

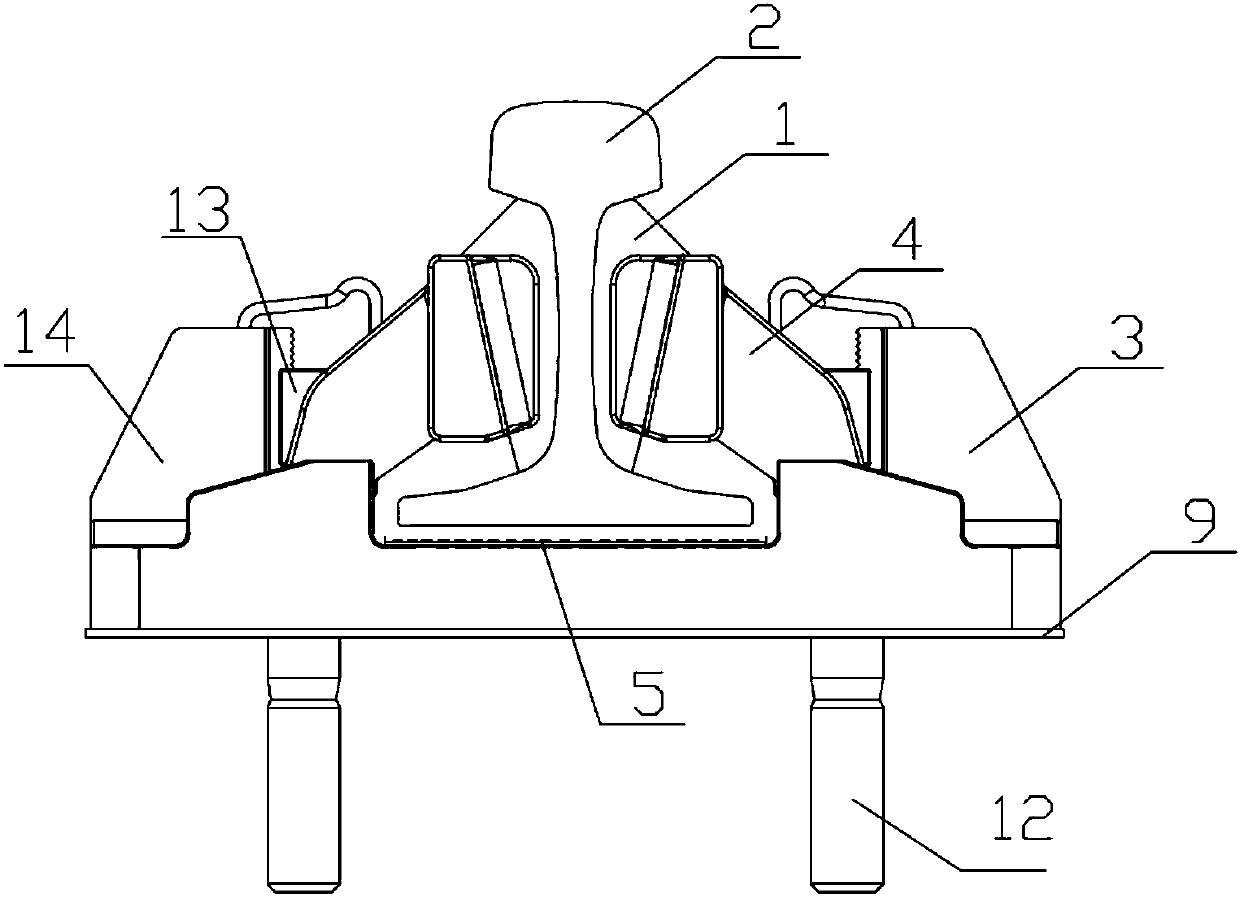

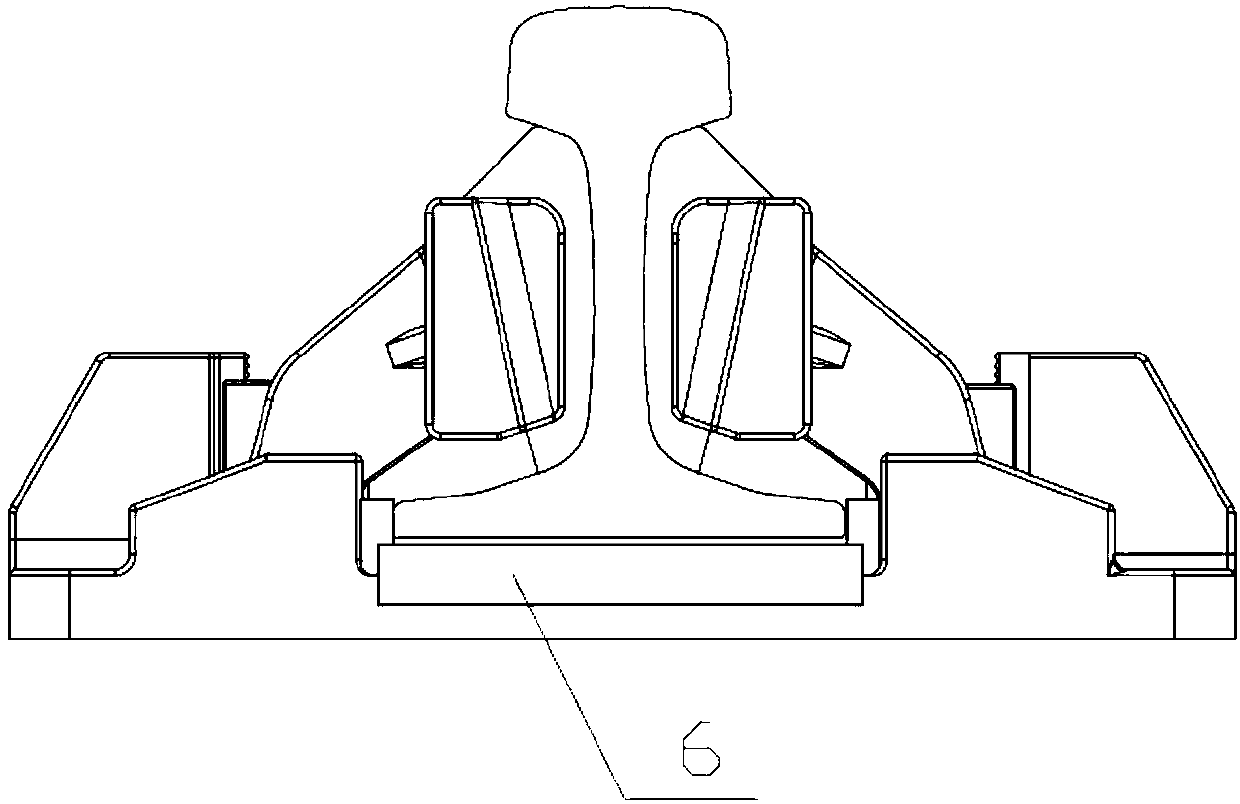

A rail torsion limiter for fastening system

A rail torsion limiter for a fastener system. The fastener system includes a rail and an elastic block buckled on the lower jaw of the rail head of the rail. The elastic block is supported and positioned by a side panel fixed on a base plate under the rail. The rail The anti-torsion limiter includes a rail foot limiter clamped between the rail foot of the steel rail and the side panel for limiting the lateral movement and torsion of the steel rail. The invention adds a part to the existing fastener system, that is, the rail anti-torsion limiter, which is installed at the rail foot of the rail, and is used to restrain the rail foot of the rail, effectively restricting the rail foot The horizontal movement and torsional swing reduce the corrugation and squealing; at the same time, the fastening system retains the characteristics of simple structure and convenient installation and adjustment, which is very suitable for ballastless and ballasted track bed lines.

Owner:洛阳双瑞橡塑科技有限公司

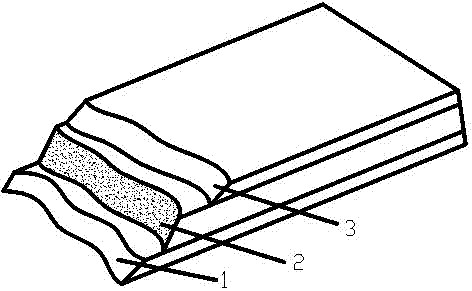

Environmentally friendly wood fragrance board synthesized by using waste circuit board and plant fiber and its manufacturing process

ActiveCN102689347BStrong enoughHigh strengthLayered productsWood working apparatusProcedure AgentsWoody plant

The invention relates to an environment-friendly wood fragrance board synthesized by utilizing waste circuit boards and plant fibers and a manufacturing process thereof. Among them, the environmentally friendly woody board adopts a three-layer structure. The first layer is the first plant fiber layer composed of plant fiber powder mixed with processing aid A, and the second layer is composed of waste circuit board powder mixed with processing aid B. The circuit board layer, the third layer is the second plant fiber layer formed by mixing plant fiber powder and processing aid A. The first plant fiber layer, the circuit board layer and the second plant fiber layer are laminated sequentially. The manufacturing process of environmentally friendly woody board includes: grinding and drying plant fibers and waste circuit boards; layered feeding and paving, pre-pressing and thickness determination, initial trimming, hot pressing, trimming, and thickness determination. The environment-friendly wood incense board of the invention can be nailed and sawed, has excellent mechanical properties and high waterproof performance. Using waste circuit boards and plant fibers as raw materials for environmentally friendly wood fragrance boards can fully recycle waste circuit boards and agricultural waste, and can also reduce the production cost of environmentally friendly wood fragrance boards.

Owner:清远炬众节能环保科技有限公司

Alkali-hydrogen peroxide method-based cooking catalyst and clean pulping process

InactiveCN101823002BLower requirementHigh whitenessOrganic-compounds/hydrides/coordination-complexes catalystsChemical industryFiberPapermaking

The invention relates to an alkali-hydrogen peroxide method-based cooking catalyst and alkali-hydrogen peroxide method-based clean pulping process, which belong to the technical field of papermaking. The cooking catalyst mainly comprises the following raw materials in part by weight: 3 to 10 parts of chelant, 4 to 10 parts of magnesium sulfate, 7 to 15 parts of sodium silicate and 16 to 30 parts of urea; and the catalyst can lower the cooking temperature and pressure to enable that the cooking residual liquid keeps higher whiteness which brings convenience to cyclic utilization. The pulping process comprises the following step of: cooking the pretreated fiber raw materials by using alkali and hydrogen peroxide, wherein the cooking catalyst is added into the cooking liquor in cooking; the catalyst needed by each oven dry metric ton of pulp comprises 3 to 10 kg of the chelant, 4 to 10 kg of the magnesium sulfate, 7 to 15 kg of the sodium silicate and 16 to 30 kg of the urea. The cookingresidual liquid obtained by the process has a yellowish white color, and can be returned to the cooking equipment for the next cooking after solid impurities are removed; and when the cooking residual liquid is circularly utilized, the rinsing cost of the pulp is not increased, and the cost is low in cyclic utilization, so the alkali-hydrogen peroxide method-based cooking catalyst and the alkali-hydrogen peroxide method-based clean pulping process are favorable for saving energy and reducing emission.

Owner:金永安 +2

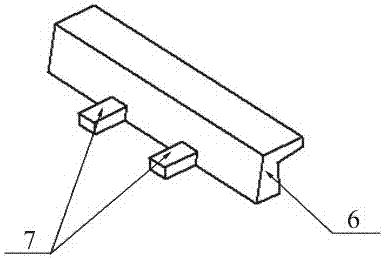

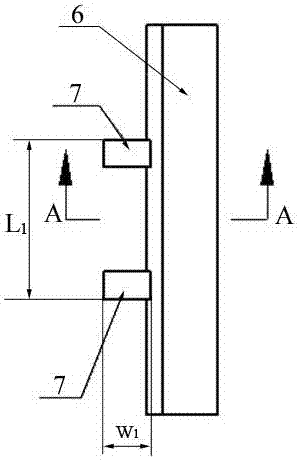

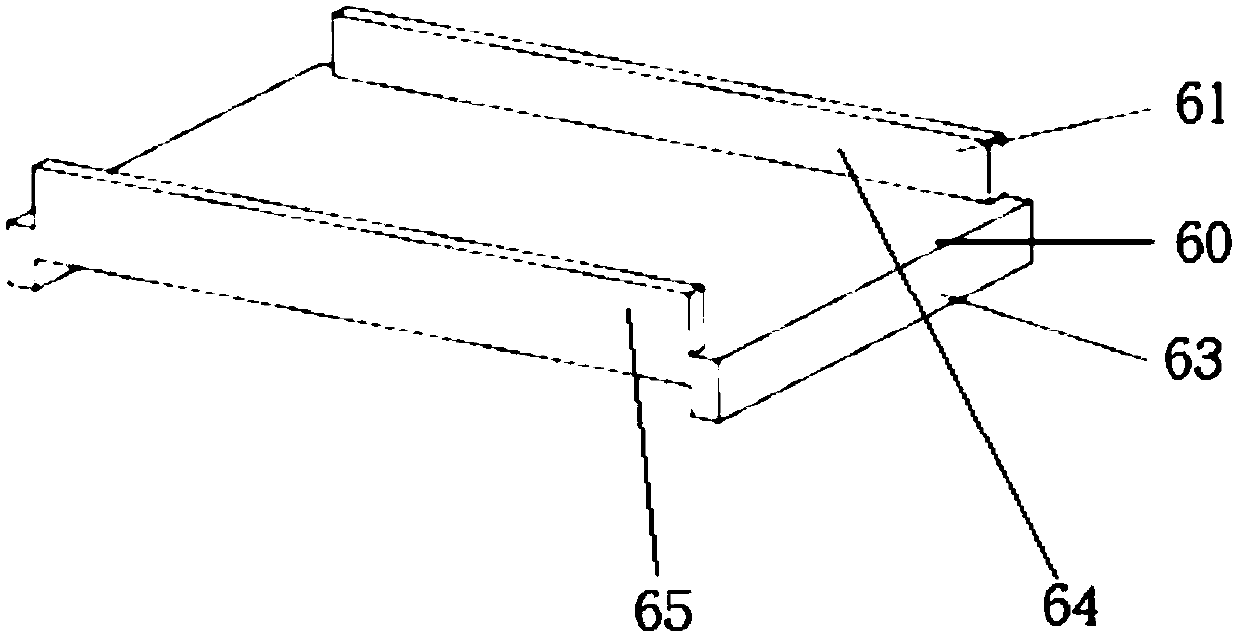

Rail anti-torsion limit rail lower pad plate used for a fastening system

PendingCN109252426AReduce lateral movementReduce torsional oscillationRail fastenersEnvironmental soundsTorsional oscillations

The invention discloses a rail anti-torsion limit rail lower pad plate used for a fastening system. The fastening system comprises a rail (2), a bottom plate (3) and a rail lower pad plate (6). The rail lower pad plate (6) is positioned between the bottom plate (3) and the rail. The bottom plate is provided with a finite position piece. The lower rail pad plate comprises a base plate (60), whereinthe base plate comprises a set of mutually parallel opposite sides, wherein the mutually parallel opposite sides are provided with stopping protrusions (61) perpendicular to the base plate, and the stopping protrusions and the base plate form a groove structure. The limiting protrusion (61) is positioned between the rail pin and the bottom plate limiting member. The invention effectively reducesor even eliminates the lateral movement and torsional oscillation of the rail, so as to reduce or even eliminate the generation of the rail corrugation, reduce the noise and the environmental sound pollution, improve the ride comfort and eliminate the hidden trouble of the train operation. At the same time, the characteristics of simple structure and convenient installation and adjustment of the fastener system are retained, which is very suitable for ballastless and ballasted track lines.

Owner:洛阳双瑞橡塑科技有限公司

Continuous reduction annealing furnace for sheet metal strips

InactiveCN102586577BIncrease productivitySmall footprintFurnace typesHeat treatment furnacesMetal stripsInsulation layer

The invention discloses a reduction annealing furnace for continuous reduction and heat treatment of sheet metal strips. By utilizing the reduction annealing furnace, reduction descaling of hot-rolled strips or annealing treatment of cold-rolled strips can be continuously performed in a high-efficient, low-cost and high-quality manner. The reduction annealing furnace comprises a heating reductionsection furnace body, an intermediate transition section channel and a cooling section furnace body, wherein the heating reduction section furnace body comprises an inner furnace shell, an outer furnace shell and an intermediate heat insulation layer, a furnace chamber which is of a hollow square-shaped structure is formed by the furnace shells and the intermediate heat insulation layer, the strips are introduced into the furnace chamber after being opened by an uncoiler at the center of the furnace body, revolved for a plurality of circles through the guide of a guide roller table in the furnace chamber, then heated, reduced or annealed and then led out of the furnace body, and further enter into the cooling section furnace body via the intermediate transition channel, the cooling section furnace body is of a hollow square-shaped cooling chamber constituted by the multiple sections of housings, and the strips are revolved for the plurality of the circles in the cooling chamber, cooled in a non-oxidation manner and coiled into strip coils by a coiling machine. The reduction annealing furnace disclosed by the invention has the advantages of low equipment investment, small floor area, low production cost and good product quality.

Owner:UNIV OF SCI & TECH LIAONING

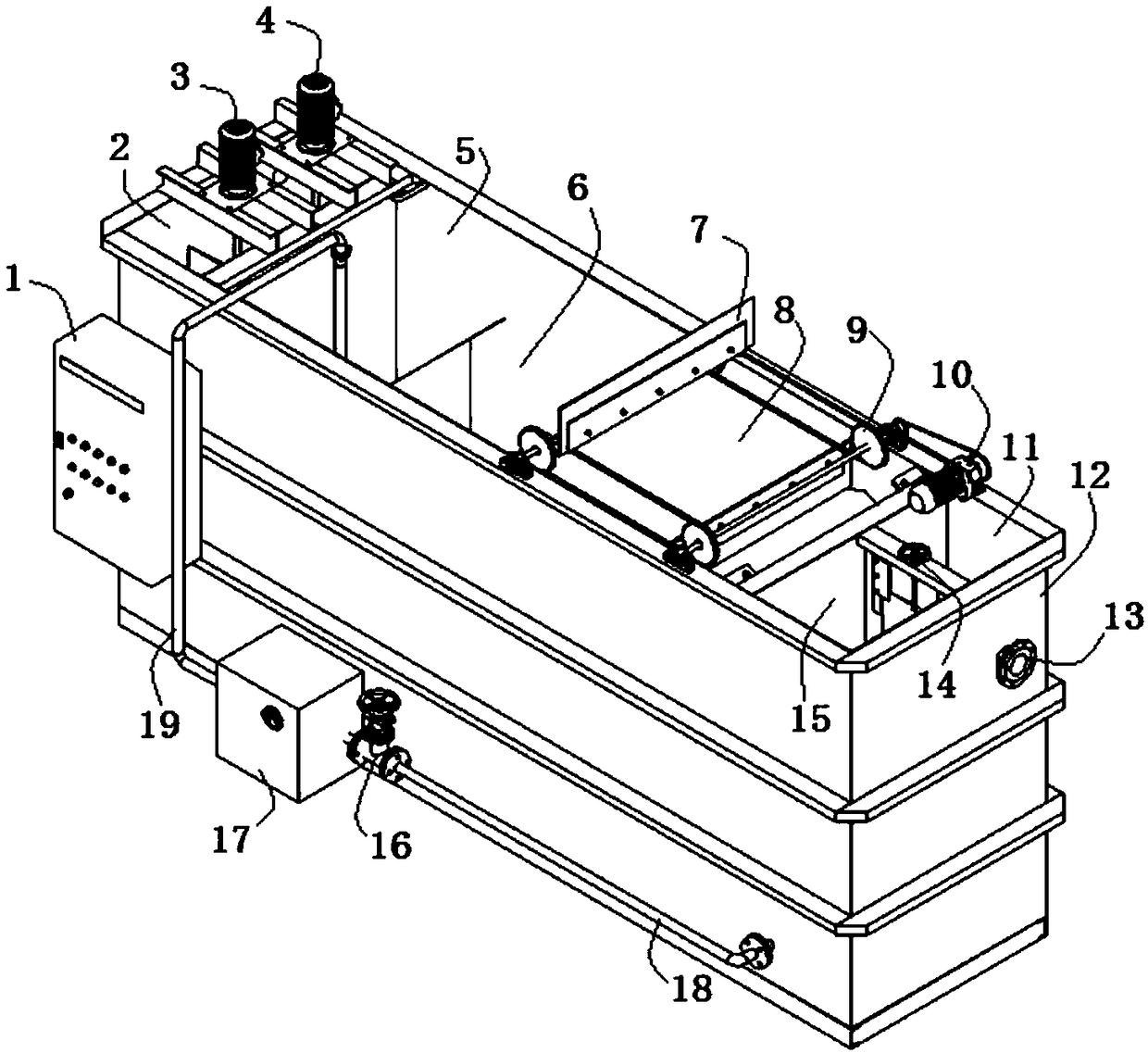

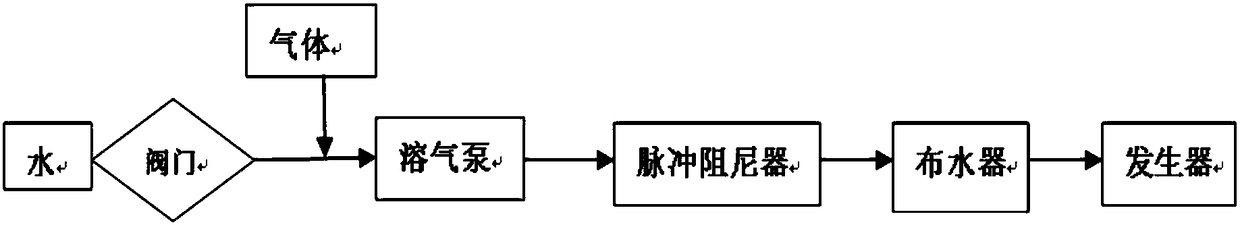

Nano sieve water treatment equipment and technology

PendingCN108164047AReduce pollutionReduce or even eliminate pollutionWater treatment parameter controlSpecific water treatment objectivesMicro nanoChemical oxygen demand

The invention relates to nano sieve water treatment equipment and a technology. A stirring reaction area, a micro-nano bubble dissolution area, a nano sieve floatation area, a slag scraping system anda water production area are integrated in a box structure; a micro-nano bubble generation system is additionally arranged between the water production area and the micro-nano bubble dissolution areafor internal circulation of water treatment; indexes such as turbidity, a COD (chemical oxygen demand), total phosphorus and ammonia nitrogen of a water body are effectively reduced; and therefore, box equipment achieves functions of a small-sized movable sewage treatment plant.

Owner:北京爱尔斯生态环境工程有限公司

Method and equipment for manufacturing solar battery

ActiveCN101752457BImprove performanceQuality improvementFinal product manufactureChemical vapor deposition coatingComputer moduleEngineering

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Gas diverting type boiler

InactiveCN1268872CReduce or even eliminate pollutionLow costSolid fuel combustionCombustion apparatusAtmospheric airEngineering

The invention relates to a gas bypass type boiler. It includes main body, funneled bunker set on top of main body, taper dry distillation tube which communicates with discharge hatch and closes to combustion layer of hearth. There is a dry distillation prick in dry distillation tube between which dry distillation room is formed. There is a rotate coke-pushing ram below dry distillation prick and an air chamber below coke-pushing ram. The air chamber has an airway with an air cap. The stove can decoke and denitride effectively to reduce atmospheric pollution made by coal combustion in boiler. And acid rain is avoided. At the same time, the collected sulfur and nitrogen is used as resource, which can both save expense of fathering air pollution and create fortune. Enormous social and economic benefit can be made. Cokes fallen from dry distillation room diffuse around. There are carbon, fire and ash from the top down. The ash will not be coking because there is no reducing gas in it. So it can be very easily discharged from ash expeller. The invention can be applied in kinds of boilers and kiln hoods in various tons.

Owner:张行修

Method for synthesizing crystallites and block crystals of nitride by multistep reaction in-situ under hydrothermal condition

InactiveCN1215972CEliminate pollutionStrong preparation controllabilityNitrogen-metal/silicon/boron binary compoundsBulk crystalElectron

A process for preparing microcrystal and bulk crystal of nitride by in-situ multi-step reaction in hydrothermal condition features that in constant temp and pressure condition, the raw materials are supplemented into reaction system continuously or multiple times for controlling the generation of crystal nuclears and the growth of crystals, and a novel reducer (hydrazine hydrate) is used to prevent the pollution of by-product to microcrystal and crystal. Its advantage is uniform granularity.

Owner:SHANDONG UNIV

Non-metal material motor gearbox

InactiveCN102862259AReduce the difficulty of production technologyIncrease productivityPolyethylene terephtalateEngineering

The invention provides a non-metal material motor gearbox, comprising a gearbox body. The gearbox body is subjected to injection molding after a plastic raw material is mixed with a glass fiber; the plastic raw material is nylon or polyethylene terephthalate dialdehyde; and a mass ratio of the plastic raw material to the glass fiber is 7 to 3. The gearbox is made of plastic instead of aluminum, so that the manufacturing cost is greatly reduced. Furthermore, the plastic piece is easy to machine and produce in a large batch; and the production efficiency is improved.

Owner:昆山瑞华电器有限公司

Flat sheet membrane pool using novel DEP electrode and membrane concentration system

PendingCN106564994AReduce or even eliminate pollutionReduce or even eliminate membrane cloggingDispersed particle separationElectricityAlternating current

The invention relates to a flat sheet membrane pool using novel DEP electrode. The flat sheet membrane pool comprises a pool body and multiple flat sheet membrane parts. The flat sheet membrane parts are arranged at intervals in the pool body, which is connected to a raw water input pipe and a concentrated water output pipe. The flat sheet membrane part comprises a sheet metal electrode subassembly, penetration membranes and a flat sheet framework. Front and rear surfaces of the flat sheet framework are provided with the penetration membranes, between which the sheet metal electrode subassembly is arranged. The sheet metal electrode subassembly comprises two electrode plates which are respectively connected to different output ends of an alternating current power supply and are mutually insulated. The electrode plates are an integrated sheet metal part. The flat sheet framework is provided with a producing water outlet of a producing water cavity for communicating the two penetration membranes. The producing water outlet of each flat sheet membrane part is connected with a producing water output pipe. The invention also relates to a membrane concentration system of the flat sheet membrane pool using the novel DEP electrode. The invention has advantages of low cost and no pollution. The membrane concentration system has advantage of stage treatment and can output produced water with different grades and different use purposes.

Owner:INNER MONGOLIA TIANYI ENVIRONMENTAL TECH

Green synthesis process of polyamide-dendritic amine polymer

The green synthesis process of dendritic polyamide-amine (PAMAM) polymer has material methyl acrylate (MA0 and ethylene diamine (EDA) in such amount that the ratio of MA or EDA to PAMAM end group matter is 5-8. The present invention has increased material amount to result in decreased reaction side product, raised purity of destination product, no polymerization in synthesizing high algebraic PAMAM and improved product quality. The present invention has high liquid recovering rate, less pollution, simplified technological process, low synthesis cost, low equipment cost and low power consumption, and reaches the aim of green production.

Owner:HUNAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com