Method and equipment for manufacturing solar battery

A technology of solar cells and manufacturing methods, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of solar cell performance and quality degradation, affecting solar cell performance, material and financial waste, etc., to avoid product Differences in performance and quality, improved performance and product quality, the effect of eliminating contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solution of the present invention, the solar cell manufacturing method and equipment provided by the present invention will be described in detail below with reference to the accompanying drawings.

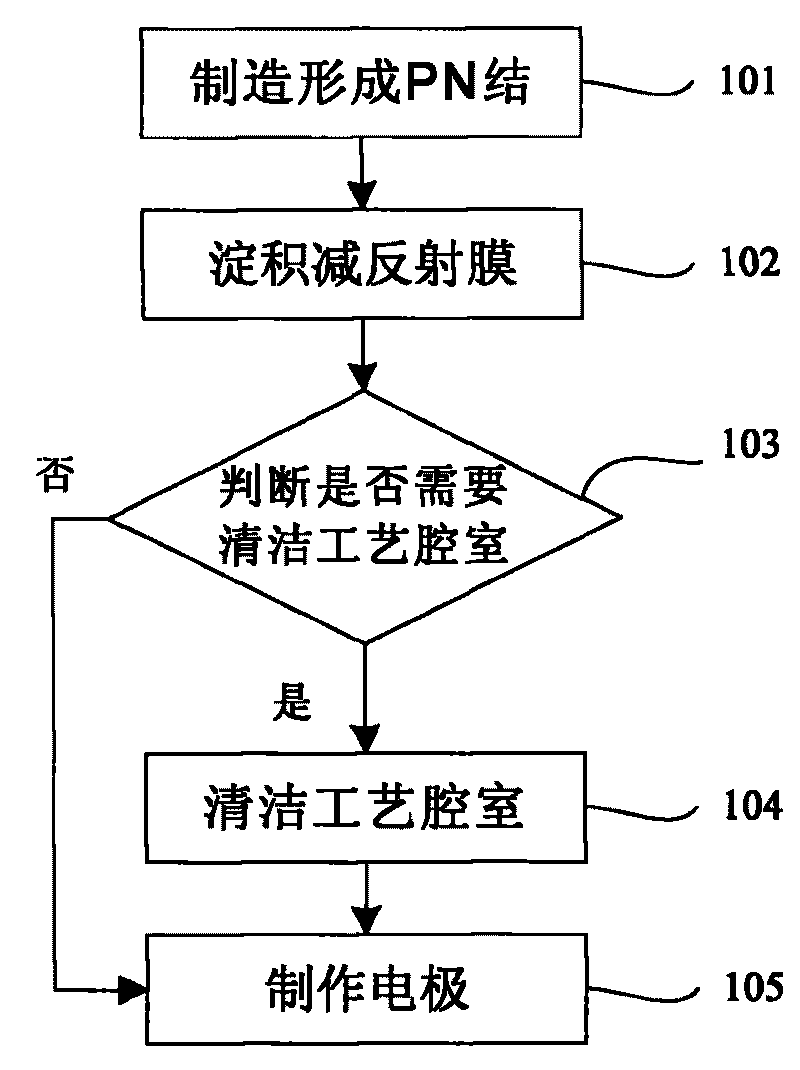

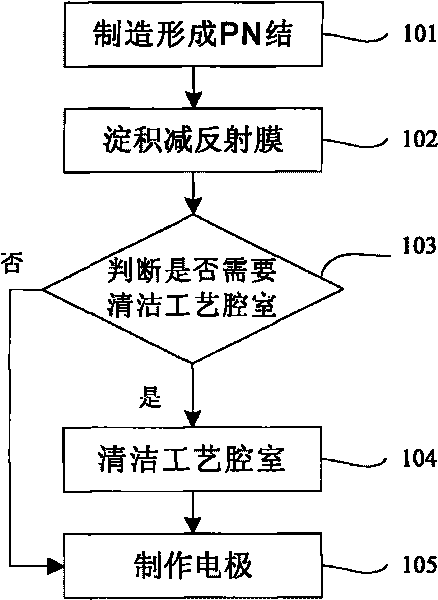

[0022] see figure 2 , the solar cell manufacturing method provided by the invention, comprises the following steps:

[0023] 101) Doping impurity atoms into the silicon wafer to form a PN junction.

[0024] Specifically, the required impurities are transported to the surface of the silicon wafer by means of a carrier gas for shallow diffusion. Here, the shallow diffusion refers to the diffusion of impurity atoms on the surface of the silicon wafer and in a relatively shallow depth range below the surface of the silicon wafer, usually the diffusion depth is only a few hundred nanometers. Then, with the help of high temperature treatment, the impurity atoms pre-attached at the shallow layer cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com