Solar heat storage greenhouse and building method thereof

A technology of solar energy and greenhouses, which is applied in the field of plant cultivation greenhouses, can solve the problems of low land use area, small light area, easy snow collapse, etc., achieve good heat preservation and sound insulation effects, strong light transmission, and reduce load-bearing loads Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

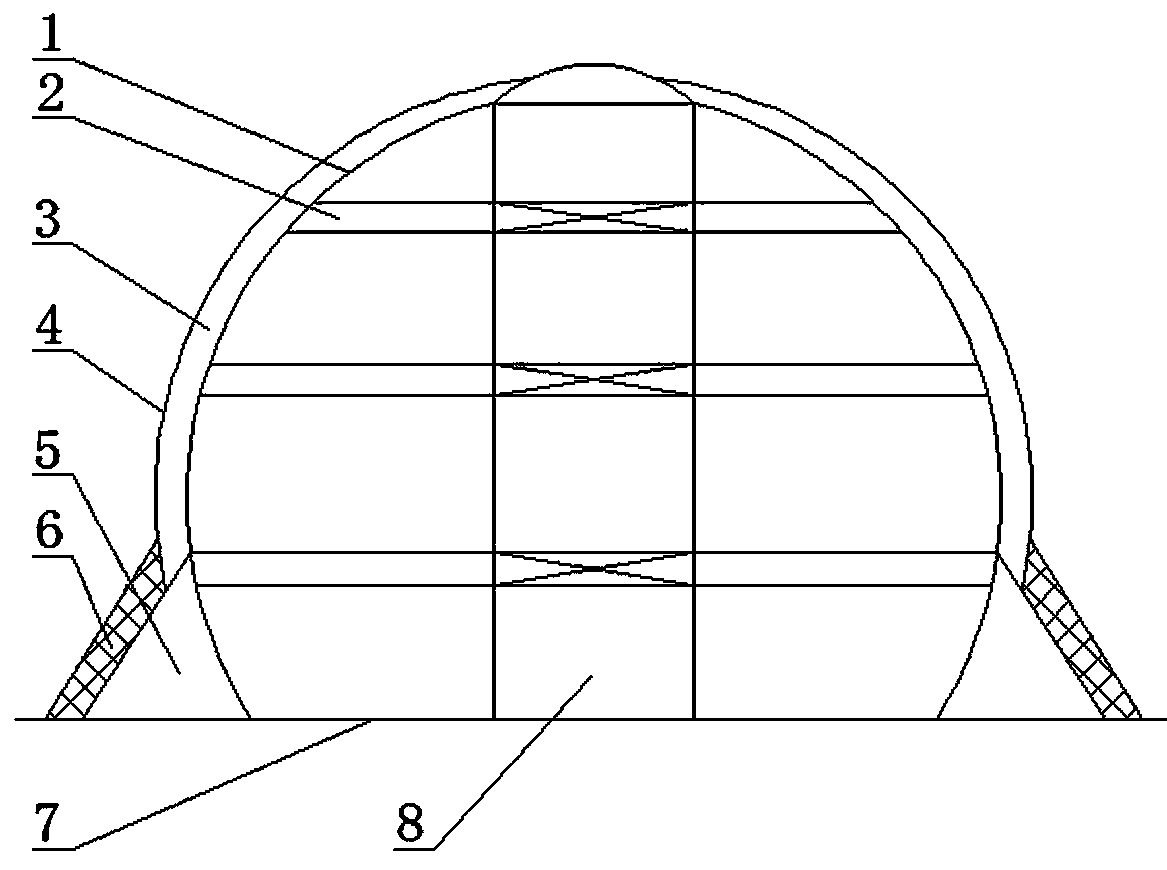

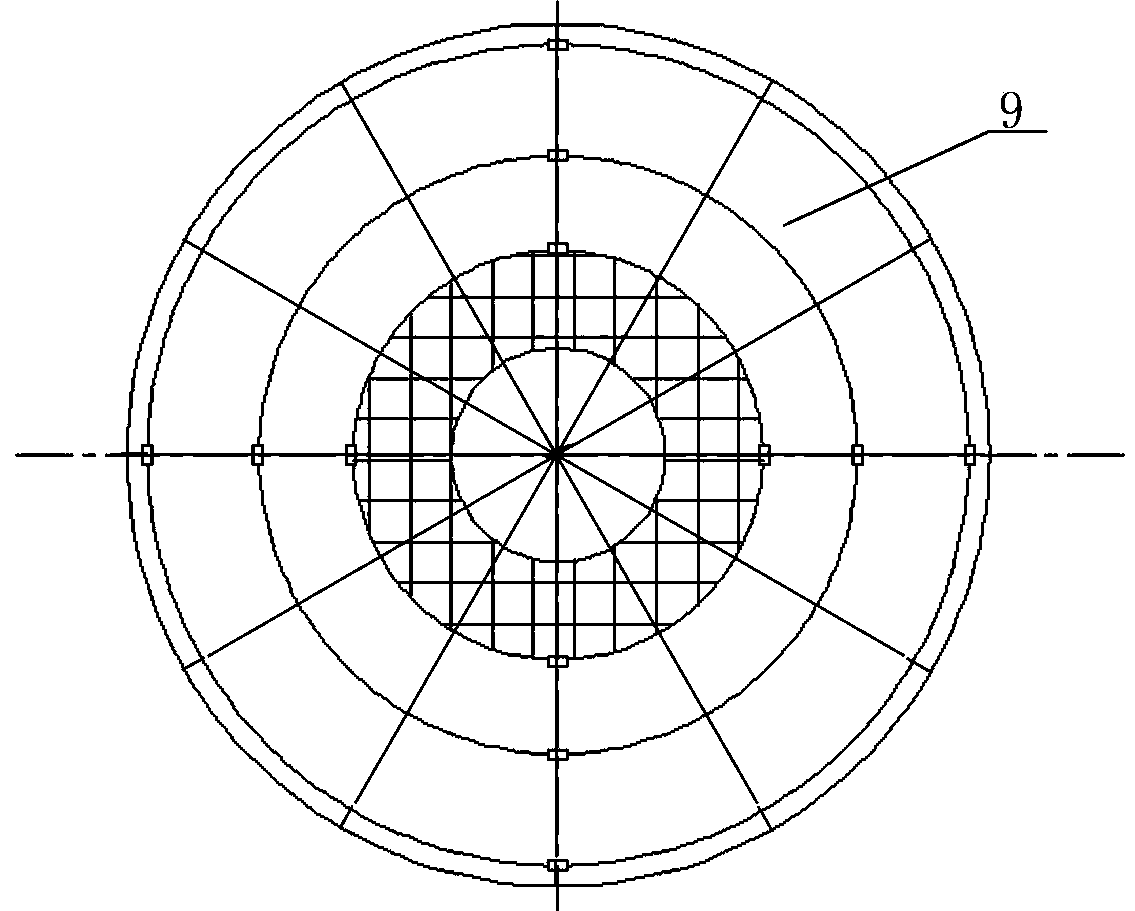

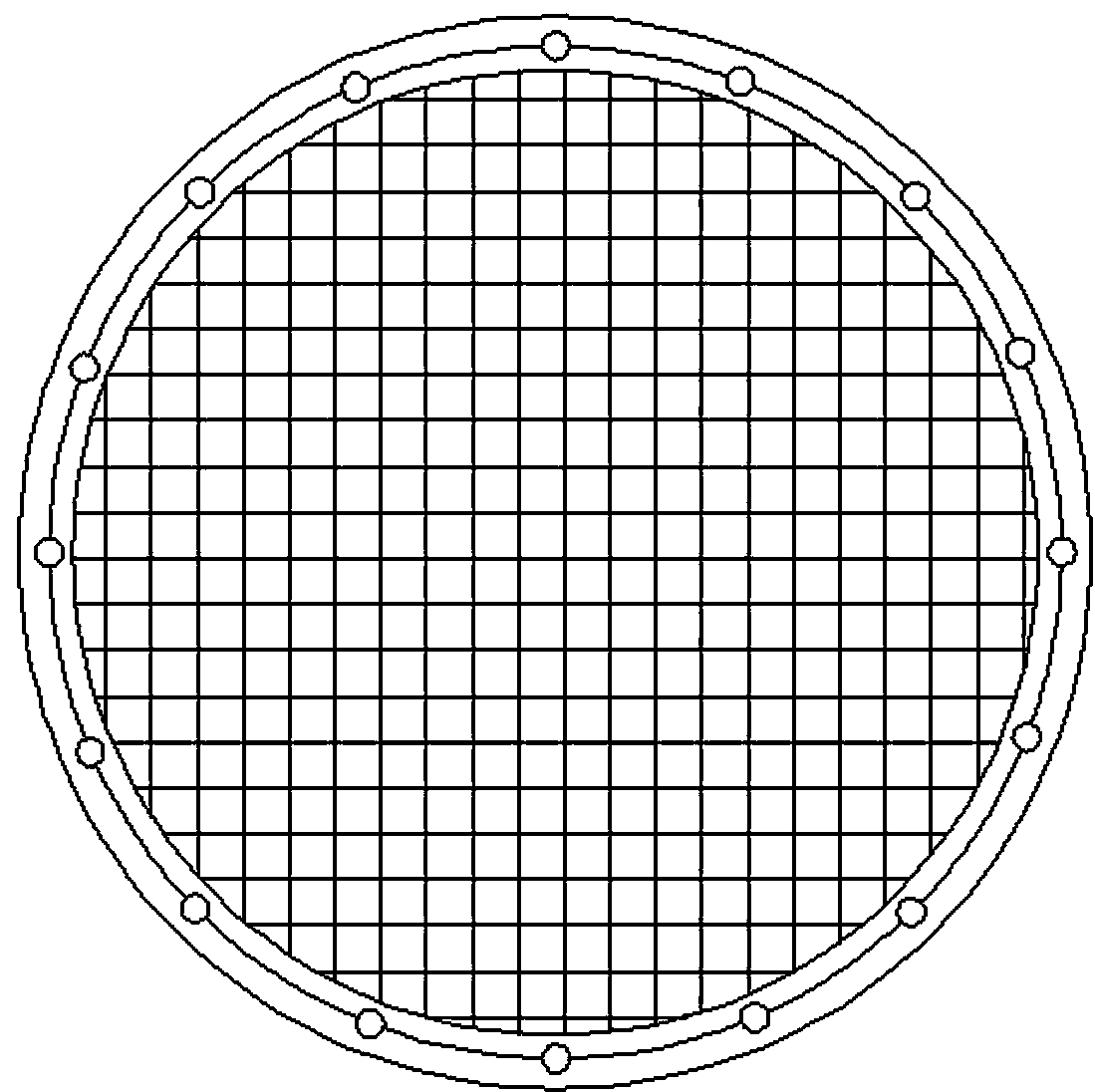

[0024] Such as Figure 1~Figure 3The shown solar heat storage greenhouse of the present invention includes a spherical frame, and components such as a light-transmitting thermal insulation layer are arranged outside the spherical frame. Several polygonal frame structures formed by bolt balls and steel pipes (such as triangles, pentagons, and hexagons, preferably using the principle of the stabilization effect of triangles, each part of the greenhouse skeleton is composed of triangular steel pipe members, and the structure is extremely stable.) form a spherical frame , surrounding the bottom of the spherical frame is surrounded by a circle of phase-change thermal storage wall panels 6, the height of the phase-change thermal storage wall panels is 1.5m, and a living space 5 is provided between the phase-change thermal storage wall panels 6 and the spherical frame (it can be built into a triangle or trapezoidal structure). Each arc-shaped structural unit is provided with inner a...

Embodiment 2

[0033] The other structures are the same, and the improved soil is composed of the following components: peat soil 45kg, plant ash 25 kg, calcium hydroxide 15 kg, iron powder 5 kg, starch 10 kg, fiber-type fermentation powder 1 kg, sodium tetraborate 0.05 kg, fertile field Powder or guano 20 kg, potassium permanganate 1 kg.

[0034] The transparent foam heat storage layer is composed of the following components: 20kg of α-dilute organic expanding agent (AEO), 20kg of hydroxyethyl cellulose, 10kg of sodium dodecylsulfonate, 5kg of sodium stearate, and 60kg of water.

Embodiment 3

[0036] The other structures are the same, and the improved soil is composed of the following components: peat soil 42kg, plant ash 20kg, calcium hydroxide 10kg, iron powder 3kg, starch 7kg, fiber-type fermentation powder 0.5kg, sodium tetraborate 0.03 kg, fertilizer powder or bird droppings 15kg, potassium permanganate 0.5kg.

[0037] The transparent foam thermal storage layer is composed of the following components: α-dilute organic expanding agent (AEO) 15kg, hydroxyethyl cellulose 15kg, sodium dodecylsulfonate 7kg, sodium stearate 4kg, water 50kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com