Continuous reduction annealing furnace for sheet metal strips

A technology of annealing furnace and furnace body, which is applied in the direction of furnace, heat treatment furnace, furnace type, etc. It can solve the problems of unsuitable reduction and descaling of hot-rolled products, large equipment investment, and high production cost, and achieves small footprint and improved surface area. The effect of high quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is specifically described below with an embodiment, which is only an application example of the present invention, and should not be construed as limiting the protection scope of the claims of the present invention.

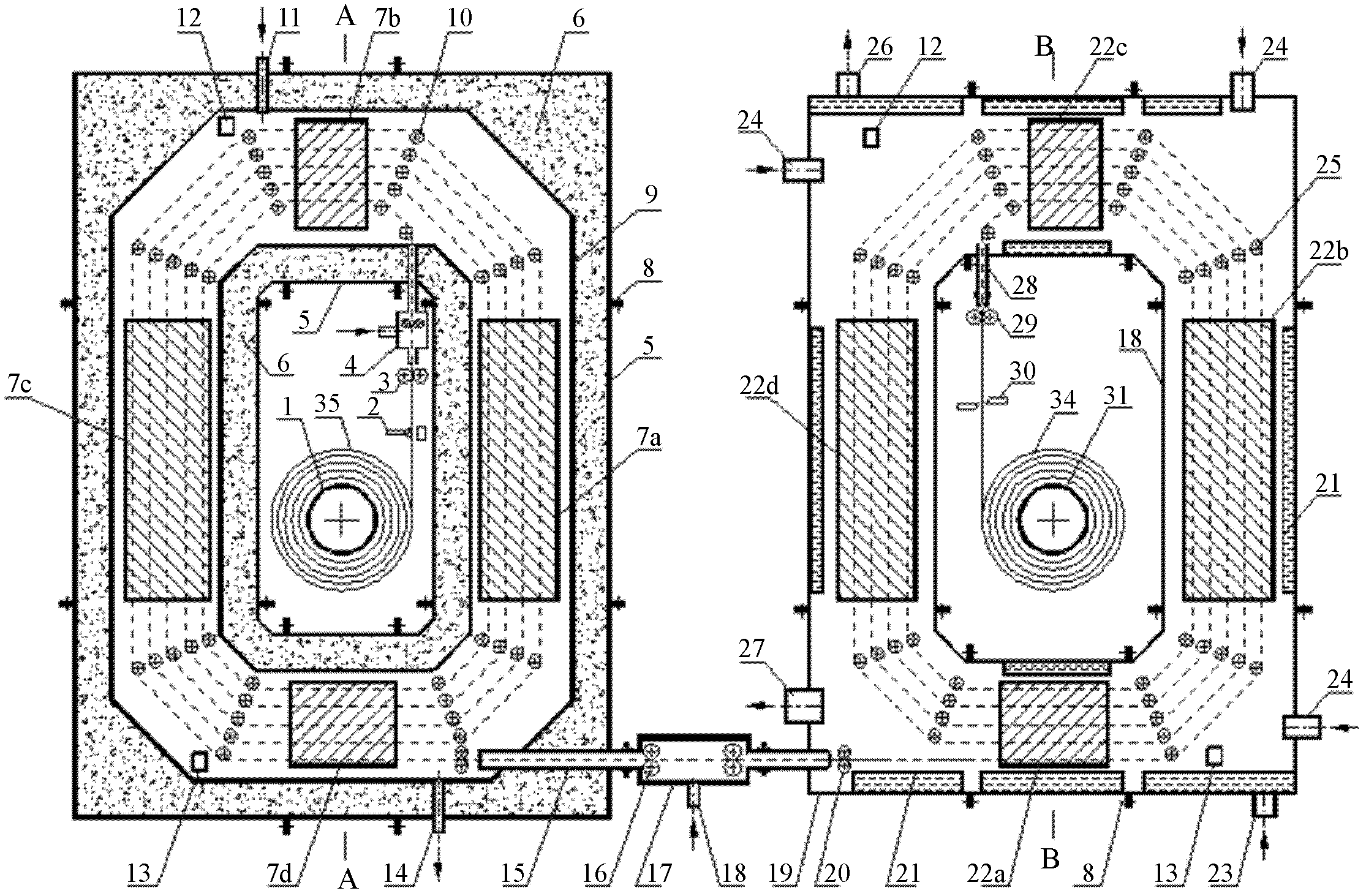

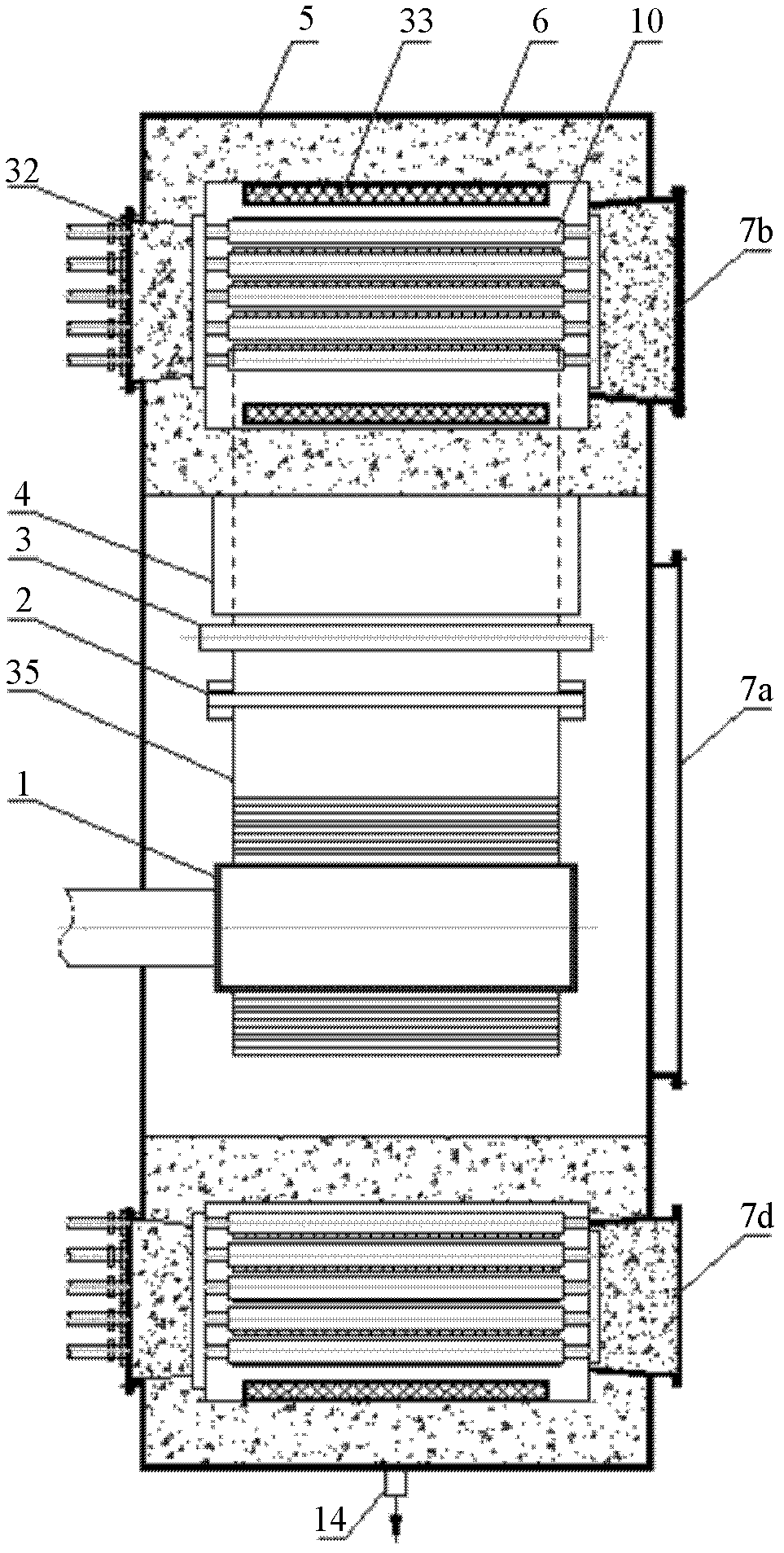

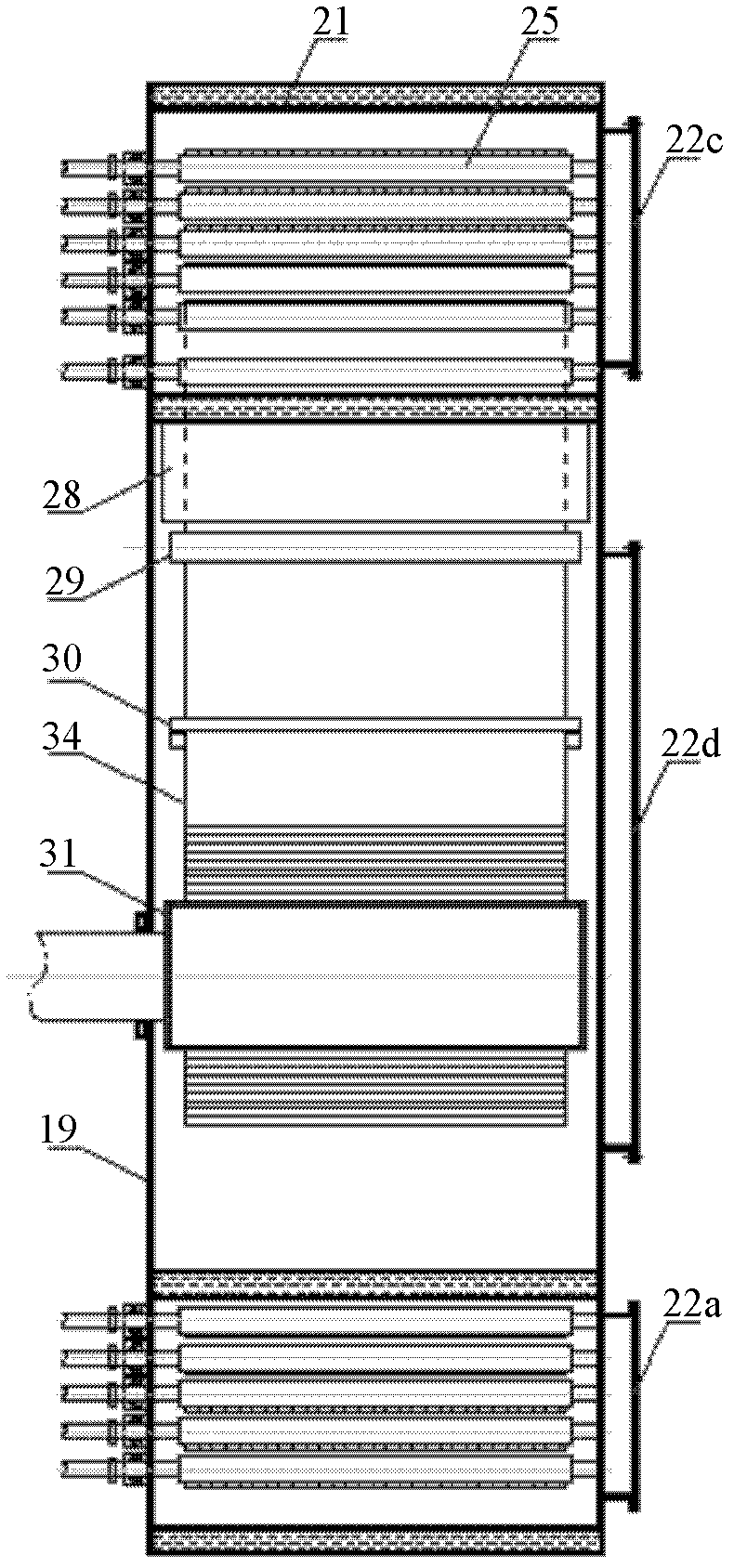

[0023] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the continuous reduction annealing furnace is composed of a furnace body in the heating reduction section, a channel in the middle transition section, and a furnace body in the cooling section. , outer furnace shell 5, insulation layer 6, furnace doors 7a, 7b, 7c, 7d in the heating and reducing section, connecting bolts 8, inner furnace shell 9, guide roller table 10 in the heating and reducing section, reducing gas inlet 11, temperature measuring instrument 12, It consists of a pressure measuring instrument 13, a reducing gas outlet 14, an explosion-proof cover plate 32, and a heater 33;

[0024] The channel in the intermediate transition section is composed of a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com