Dielectrophoresis flat osmotic membrane element

A technology of dielectrophoresis and permeable membranes, applied in the field of separation, can solve the problems of low processing efficiency and high energy consumption, and achieve the effects of low operating costs, low energy consumption, and reduced electrode production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below through the accompanying drawings and specific examples, but the present invention is not limited to the following embodiments, and any changes or alternatives made on the principle of this example all fall within the scope of the present invention. among.

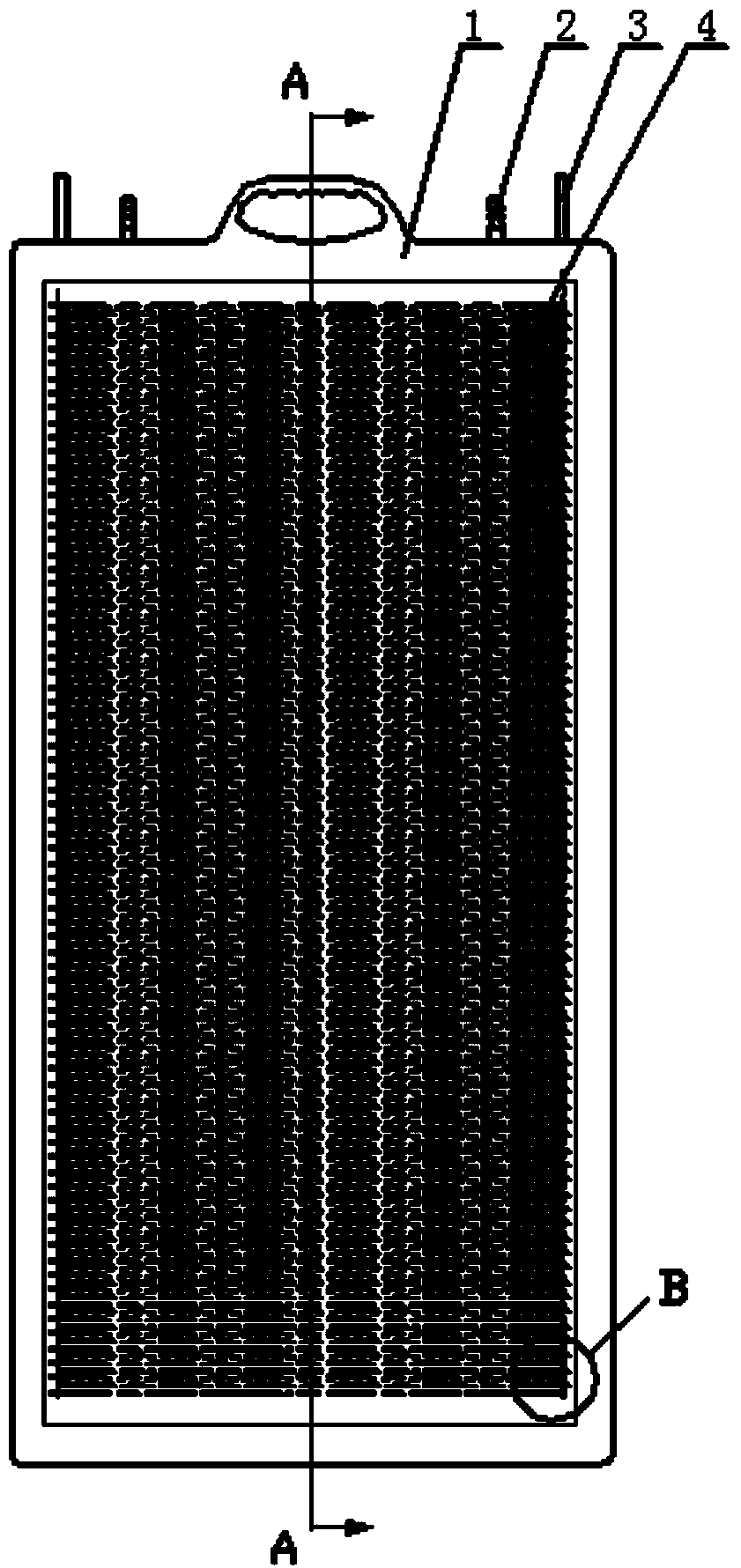

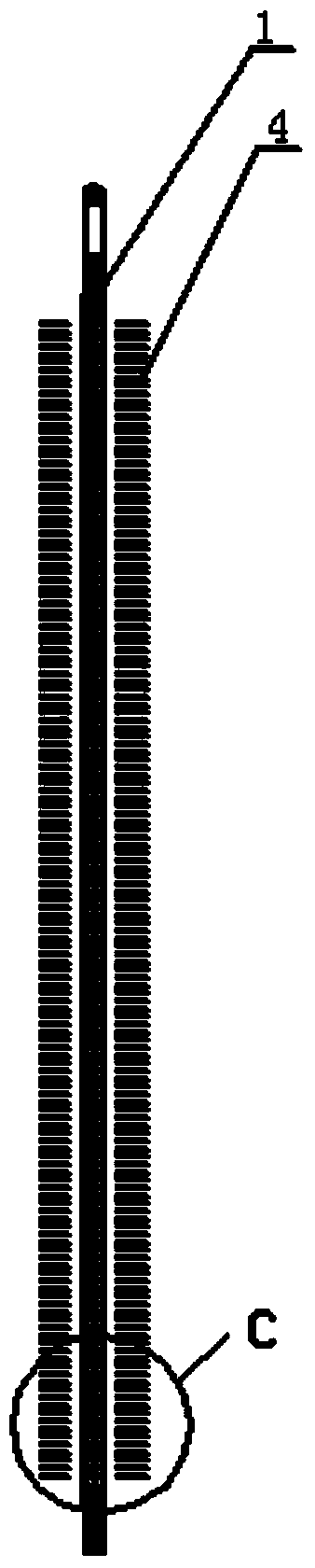

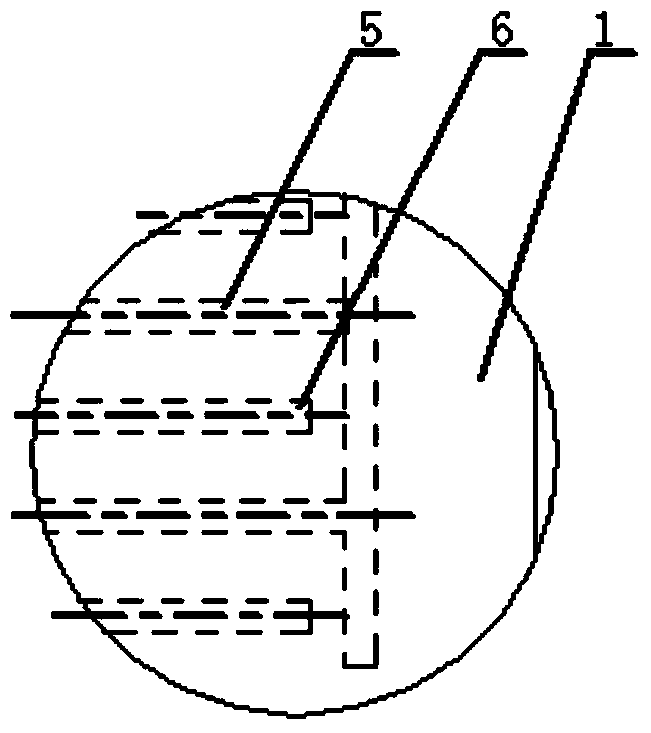

[0022] A dielectrophoretic flat plate permeable membrane element, such as figure 1 , 2 As shown, it includes a flat frame 1, an electrode 6 and a permeable membrane 4. The flat frame is made of ABS, and electrodes are evenly distributed in the horizontal direction in the flat frame, and the permeable membrane is installed on the front and rear sides of the flat frame by compression molding. The electrodes adopt a cylindrical interdigitated electrode structure. In each pair of electrodes, one electrode uses an insulated electrode, while the other electrode uses a bare electrode of anti-corrosion material to reduce energy consumption and electrode produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com