Floating type multi-phase cut-off repose angle valve

A floating type, valve body technology, applied in the direction of cocks, valve devices, engine components, etc. including cut-off devices. Achieve the effect of reducing overall cost, improving equipment running time and reducing maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

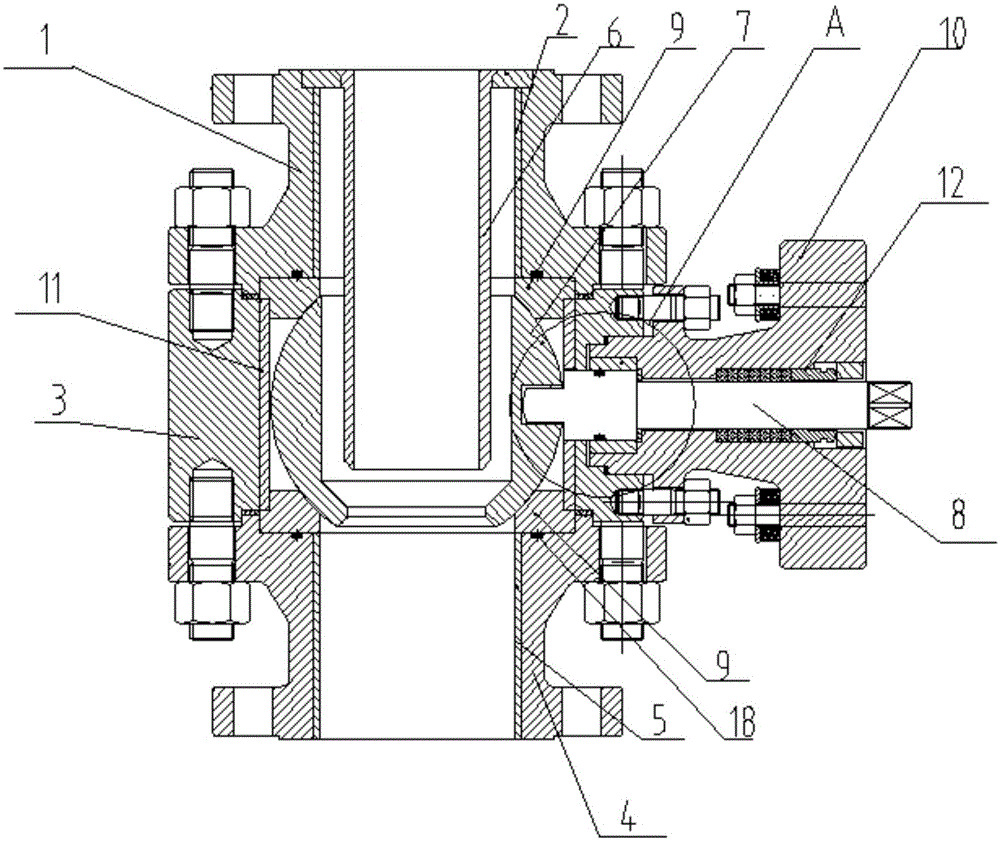

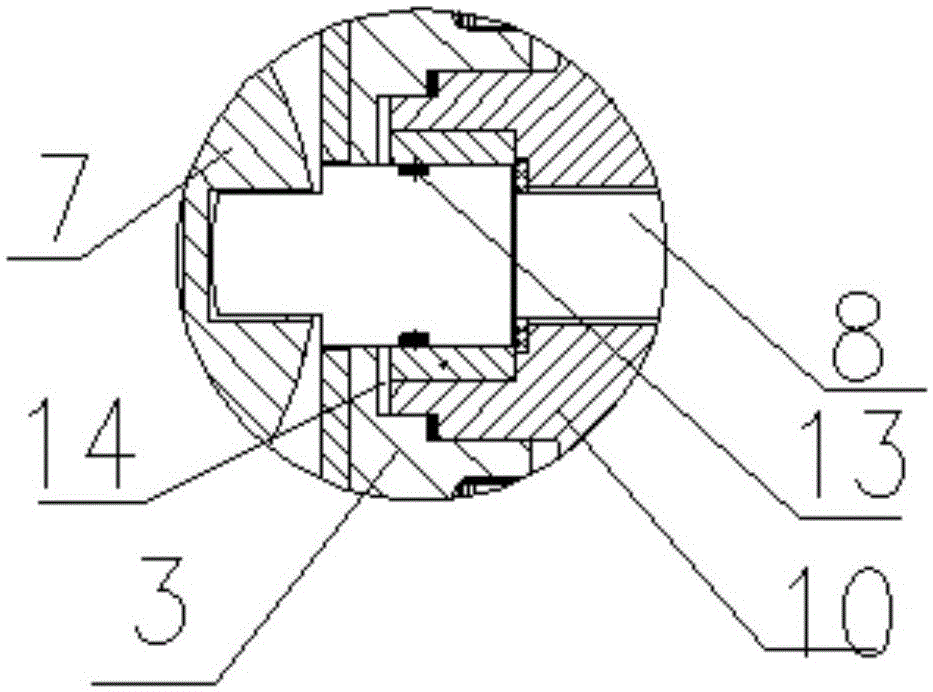

[0028] Such as figure 1 As shown, a floating multi-phase cut-off angle valve, hereinafter referred to as an angle valve, is used to control the flow of powder. The powder may be commonly used powder including coal powder, polysilicon powder and the like.

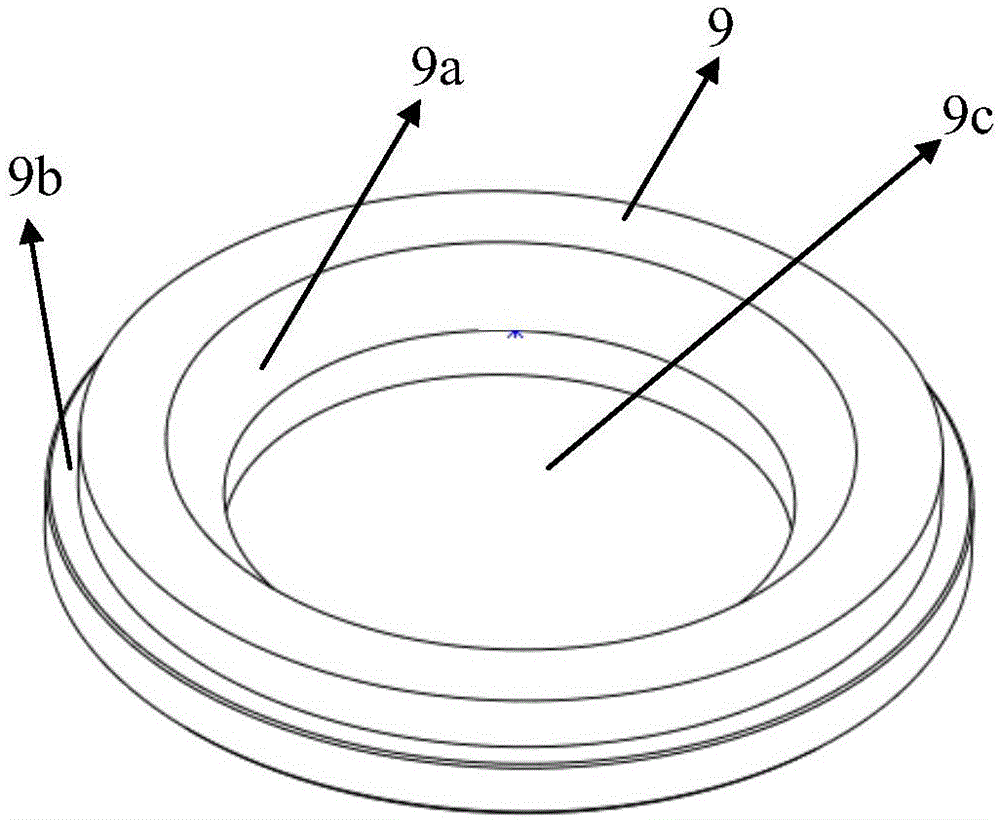

[0029] An rest angle valve includes upper flange 1, upper flange liner 2, valve body 3, lower flange 4, lower flange liner 5 and inlet conduit 6, the upper and lower flanges are connected to the valve body 3 by bolts and nuts. The upper flange liner 2 and the lower flange liner 5 are respectively embedded in the upper flange 1 and the lower flange 4 . The inner cavity at the top of the upper flange 1 is provided with an annular groove. The inlet conduit 6 extends from the upper flange liner 2 to the valve body 3. The shoulder at the upper end of the inlet conduit 6 just fits into the annular groove of the upper flange. The inlet conduit 6 The upper plane is flush with the upper plane of the upper flange, and the force on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com