Soybean oil oligomer and preparation method thereof

A technology of oligomers and soybean oil, which is applied in the fields of drying oil refining, drying oil oxidation, natural resource drying oil, etc., can solve the problem that soybean oil is not easy to dry, achieve obvious decolorization effect, save resources, and improve quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

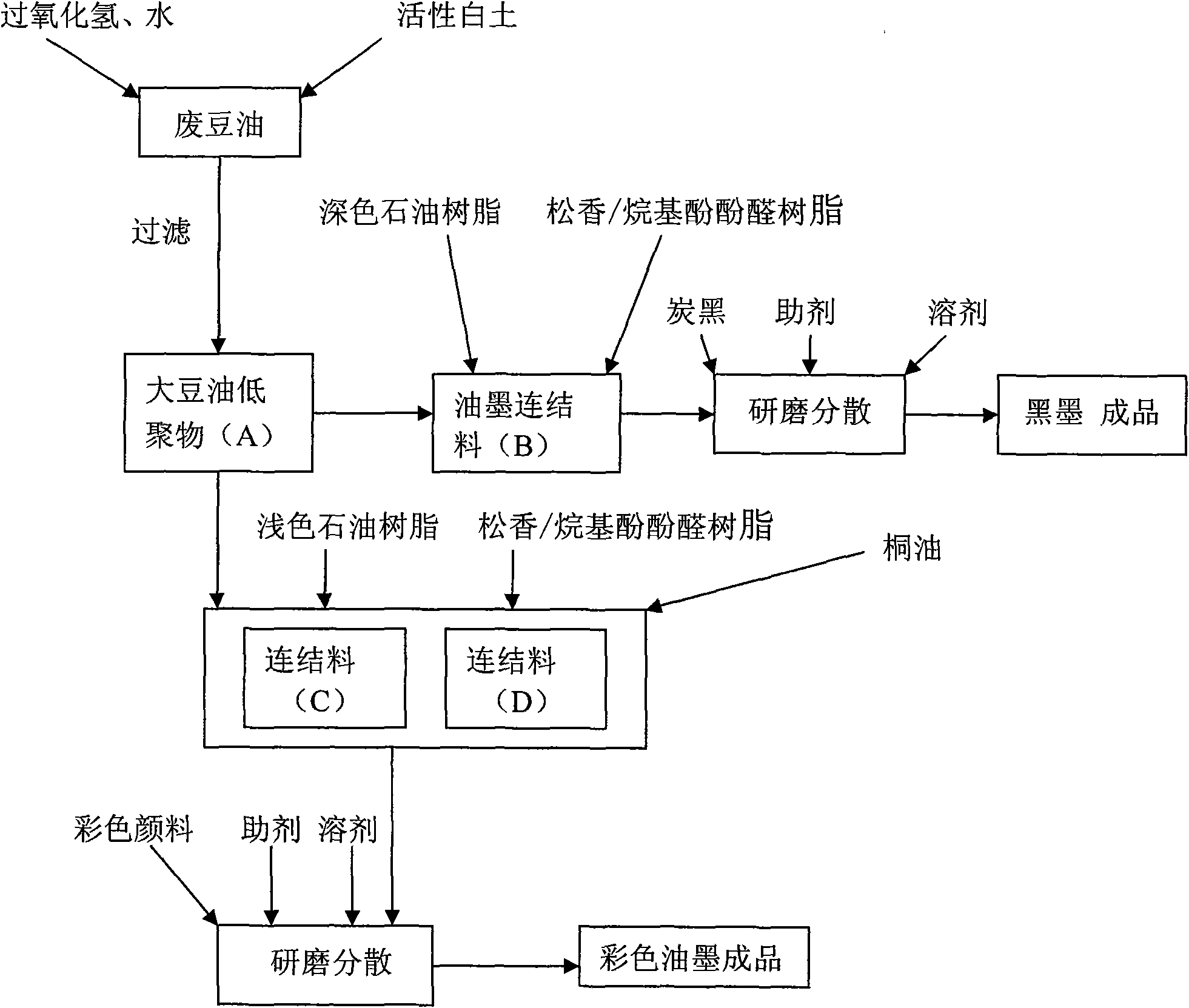

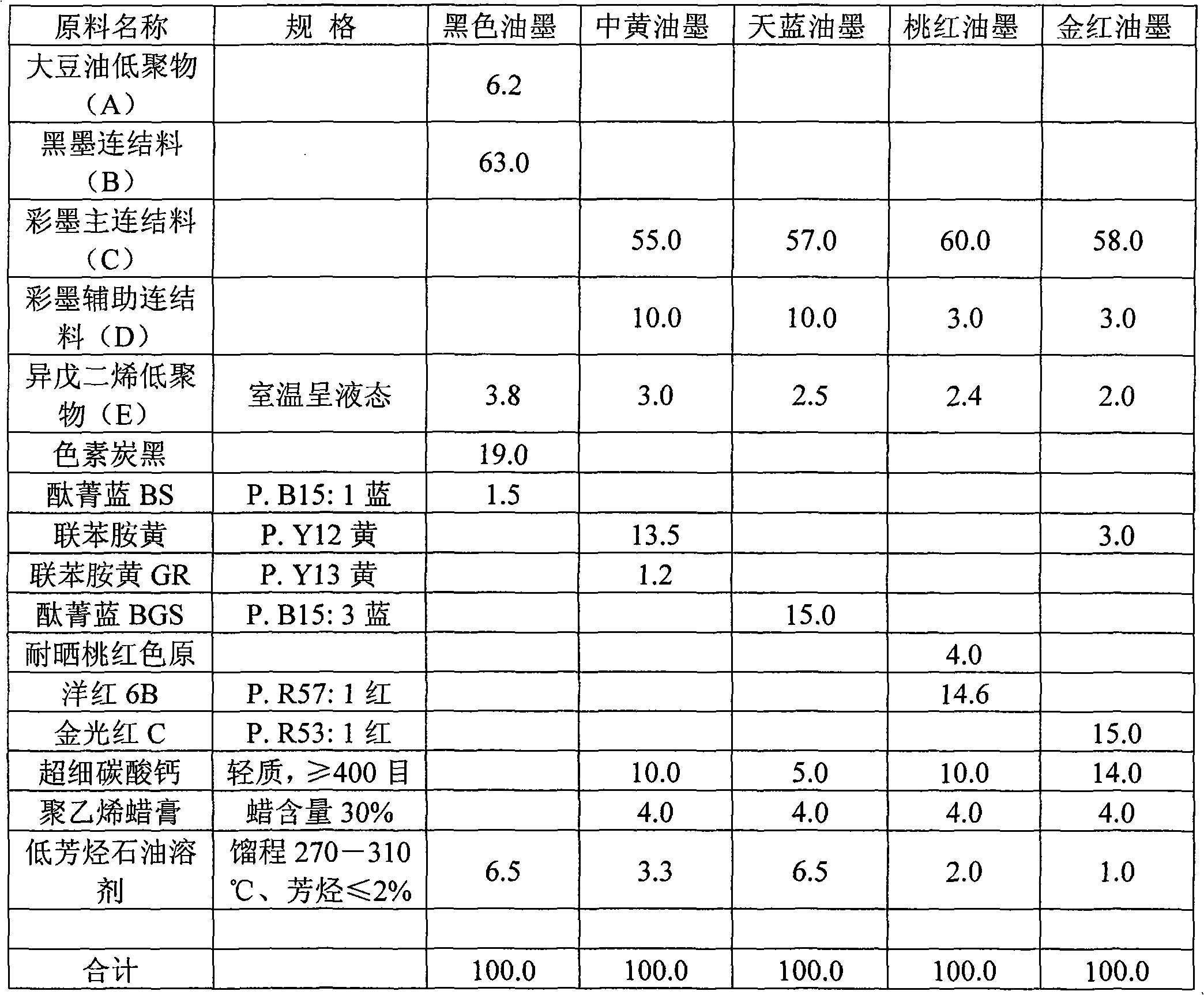

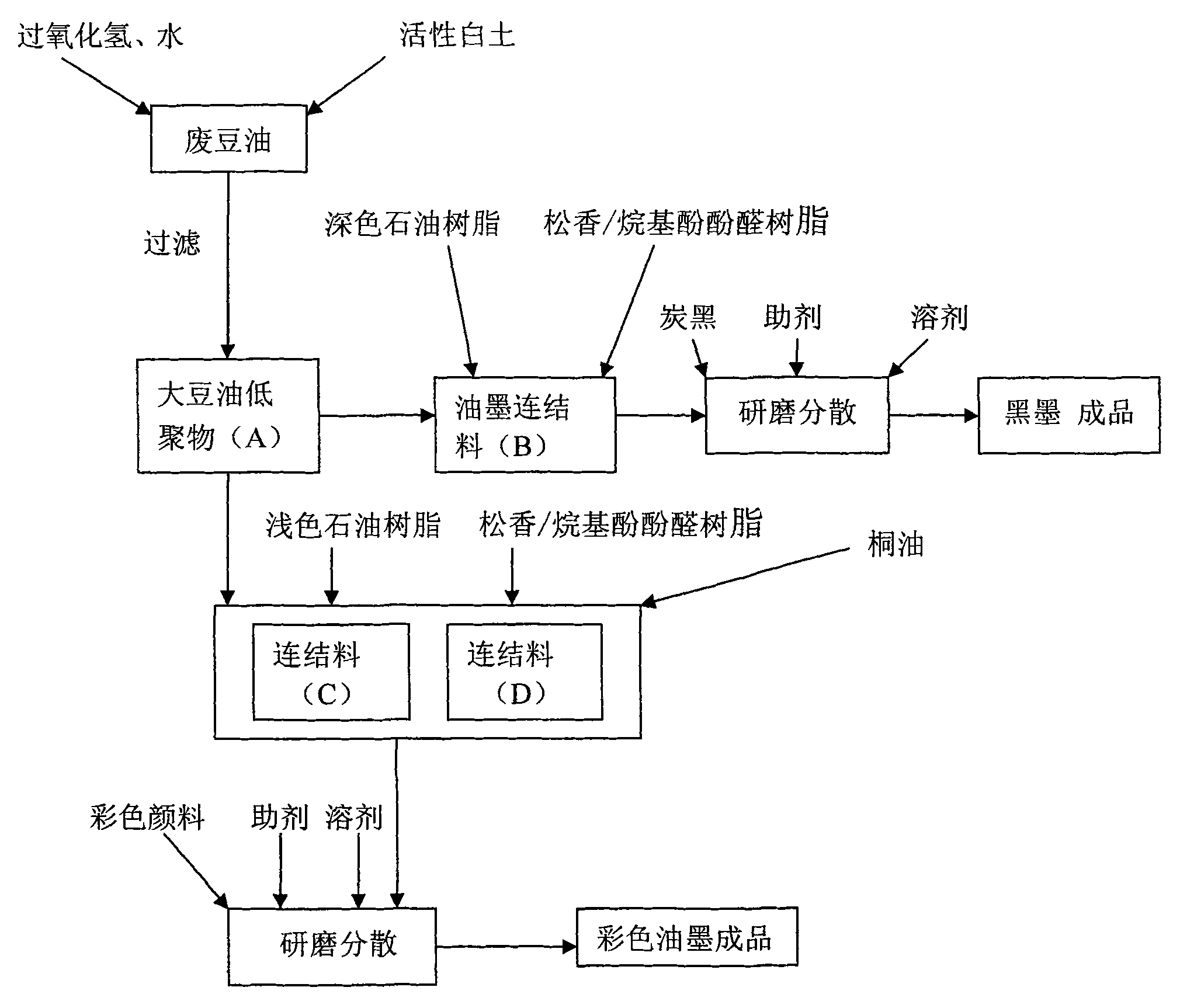

[0012] The invention relates to an environment-friendly offset printing press ink produced by recycling food processing waste soybean oil. The raw material components of the ink include soybean oil oligomer (A) extracted from food processing waste soybean oil, dark petroleum resin, rosin / The connecting material (B) for black ink made of alkylphenol phenolic resin; the connecting material (B) for color ink made of soybean oil oligomer (A) and light-colored petroleum resin, rosin / alkylphenol phenolic resin, tung oil, etc. C), (D); and an alkene low-molecular polymer (E) that is compatible with vegetable oil or petroleum solvent.

[0013] In this example, the method for preparing soybean oil oligomer (A) from recycled food processing waste soybean oil is:

[0014] Add waste soybean oil into the reaction kettle with 5% hydrogen peroxide aqueous solution for the first decolorization and decolorization treatment, separate the aqueous solution at the bottom, add a certain amount of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com