Temperature sensor liquid environment wafer level test method

A temperature sensor and liquid environment technology, applied in thermometer testing/calibration, thermometers, instruments, etc., can solve problems such as long time, low efficiency, and small number of tests at a time, and achieve time reduction, improve test efficiency, and excellent heat conduction safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

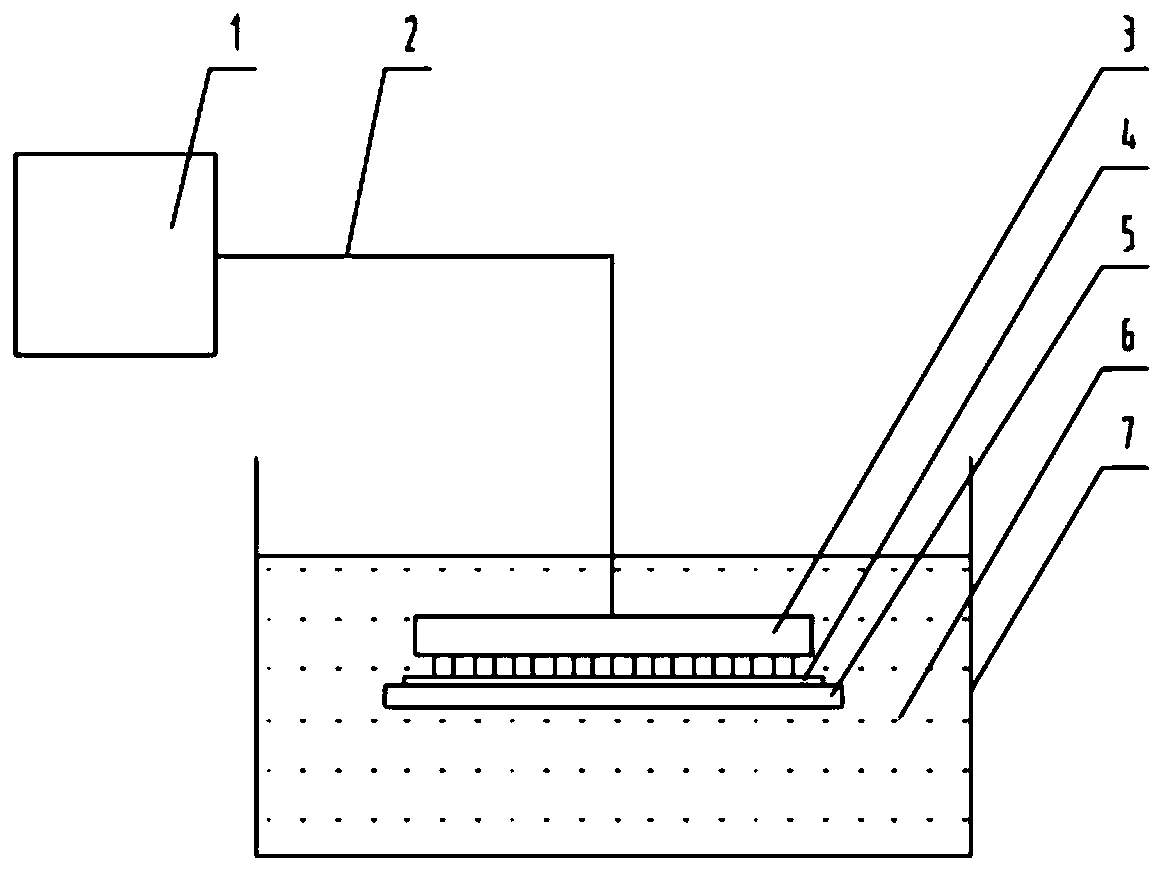

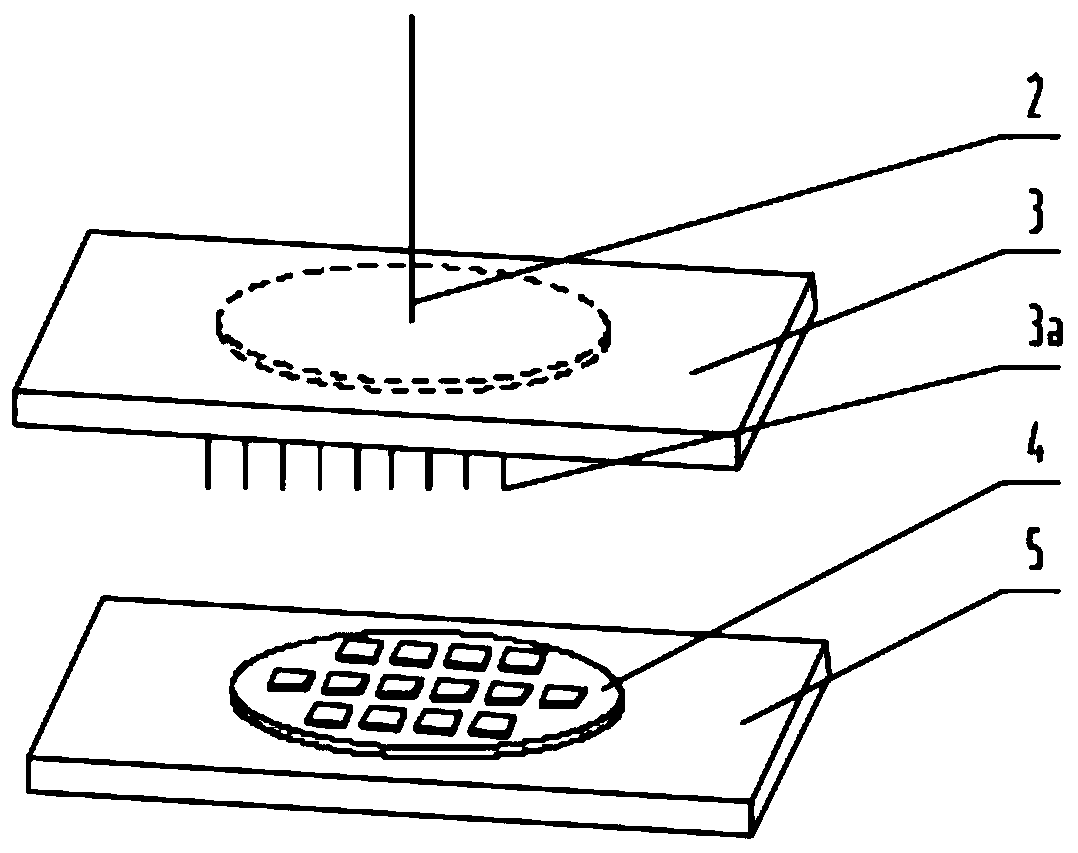

[0026] This embodiment provides a temperature sensor liquid environment wafer-level testing device, including a tester 1, a probe card equipped with a plurality of probes 3a, a platform 5 for carrying a temperature sensor wafer 4 to be tested, and A container 7 storing insulating and heat-conducting oil 6, the tester 1 is connected to the end of the probe 3a through a wire 2, the probe 3a corresponds to the temperature sensor wafer 4 to be tested, and the probe 3a 1. The temperature sensor wafer 4 to be tested and the platform 5 are submerged in the insulating heat-conducting oil 6 .

[0027] Preferably, the temperature sensor liquid environment wafer-level test device also includes a bundle tube sleeved on the wires, the top of the probe card 3 is provided with a through groove, and the wires 2 at the ends of the probes 3a pass through them in turn. The through groove and the bundle tube are connected with the tester 1, and the smoothness of the whole device can be improved b...

Embodiment 2

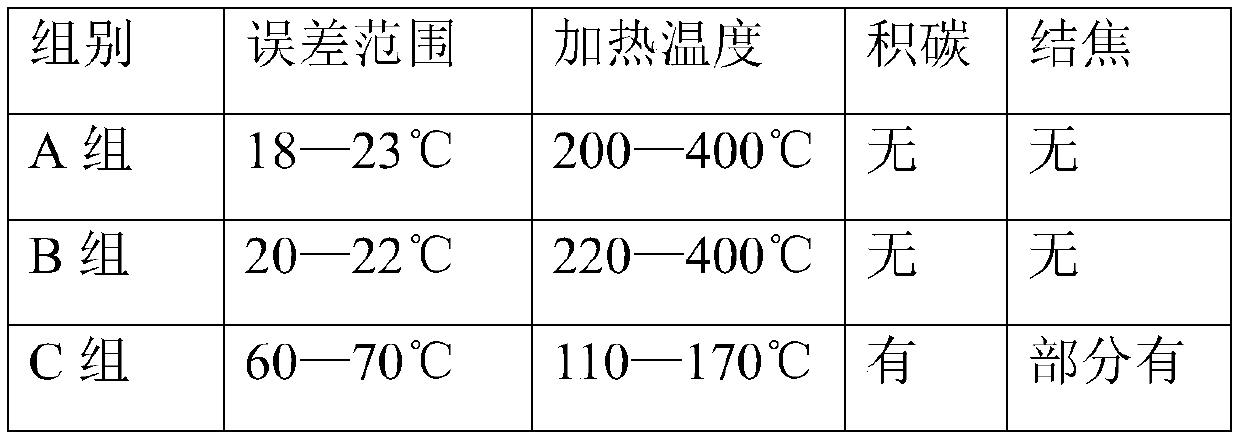

[0030] On the basis of Example 1, the raw materials for preparing the insulating heat transfer oil include cyclic body, phenyl oligomer, end-capping agent, catalyst and antioxidant, and the parts by weight of each component are 50 parts by weight of cyclic body , 18 parts of phenyl oligomer, 4 parts of end-capping agent, 0.5 part of catalyst, and 0.01 part of antioxidant. Preferably, the capping agent includes any one or a combination of two or more of phenol, ketoxime, alcohol, caprolactam and malonate. Preferably, the catalyst includes any one or a combination of two or more of organotin compounds and zinc octoate. Preferably, the antioxidant includes any one or a combination of two or more of butyl hydroxyanisole and 2,6-di-tert-butyl-4-methylphenol.

[0031] Example 2

[0032] On the basis of Example 1, the raw materials for preparing the insulating heat transfer oil include cyclic body, phenyl oligomer, end-capping agent, catalyst and antioxidant, and the parts by weigh...

Embodiment 3

[0034] On the basis of Example 1, the raw materials for preparing the insulating heat transfer oil include cyclic body, phenyl oligomer, end-capping agent, catalyst and antioxidant, and the parts by weight of each component are 55 parts by weight of cyclic body , 20 parts of phenyl oligomer, 5 parts of end-capping agent, 0.75 part of catalyst, and 0.02 part of antioxidant. Preferably, the capping agent includes any one or a combination of two or more of phenol, ketoxime, alcohol, caprolactam and malonate. Preferably, the catalyst includes any one or a combination of two or more of organotin compounds and zinc octoate. Preferably, the antioxidant includes any one or a combination of two or more of butyl hydroxyanisole and 2,6-di-tert-butyl-4-methylphenol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com