Low-ratio biomass circulating fluidized bed boiler and combustion method thereof

A technology of circulating fluidized bed and biomass fuel, which is applied in the direction of fluidized bed combustion equipment, combustion method, fuel burned in molten state, etc., and can solve tempering and output drop, slagging on the grate, coking of bed materials, etc. problems, achieve the effects of reducing power consumption, improving combustion efficiency, and less ash accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

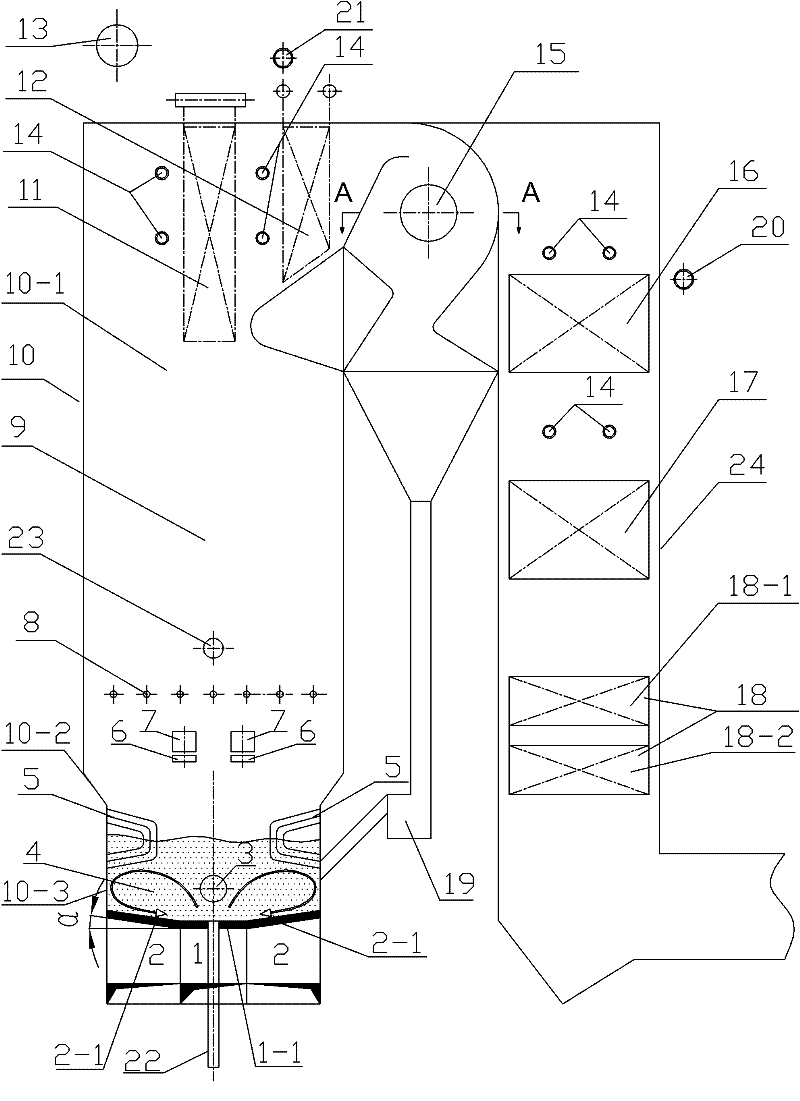

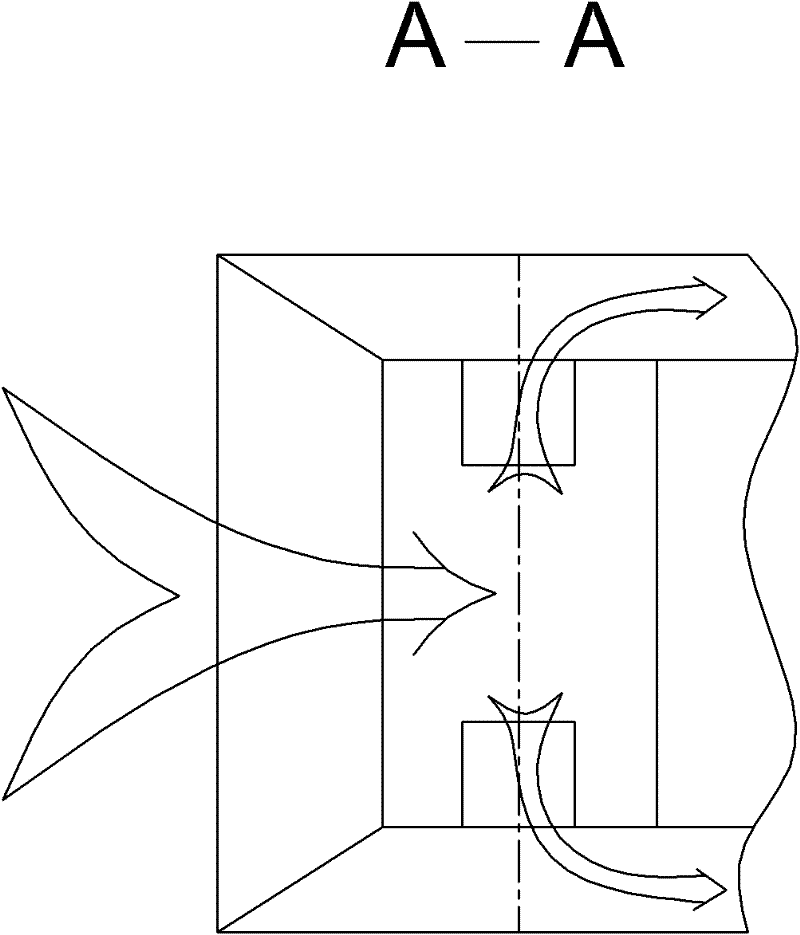

[0023] Specific implementation manner one: such as Figure 1~2 As shown, the low-rate biomass circulating fluidized bed boiler of this embodiment includes a furnace body 10, a tail shaft flue 24, an economizer 17, an air preheater 18, a furnace door 3, a buried pipe 5, and biomass fuel Feeding port 7, secondary air port 8, bed material feeding pipe 23, drum 13, soot blower 14, medium temperature steam-cooled cyclone separator 15, feeder 19, first stage desuperheater 20 and second stage The desuperheater 21, the boiler also includes a middle air chamber 1, a side air chamber 2, a middle air distribution plate 1-1, a side air distribution plate 2-1, a slag discharge pipe 22, a seeding tuyere 6, a top intermediate temperature screen type The superheater 11, the high temperature convective heat exchanger 12 and the low temperature convective heat exchanger 16; the furnace body 10 is surrounded by a membrane water wall, and the furnace body 10 connects from the upper furnace body 10-...

specific Embodiment approach 2

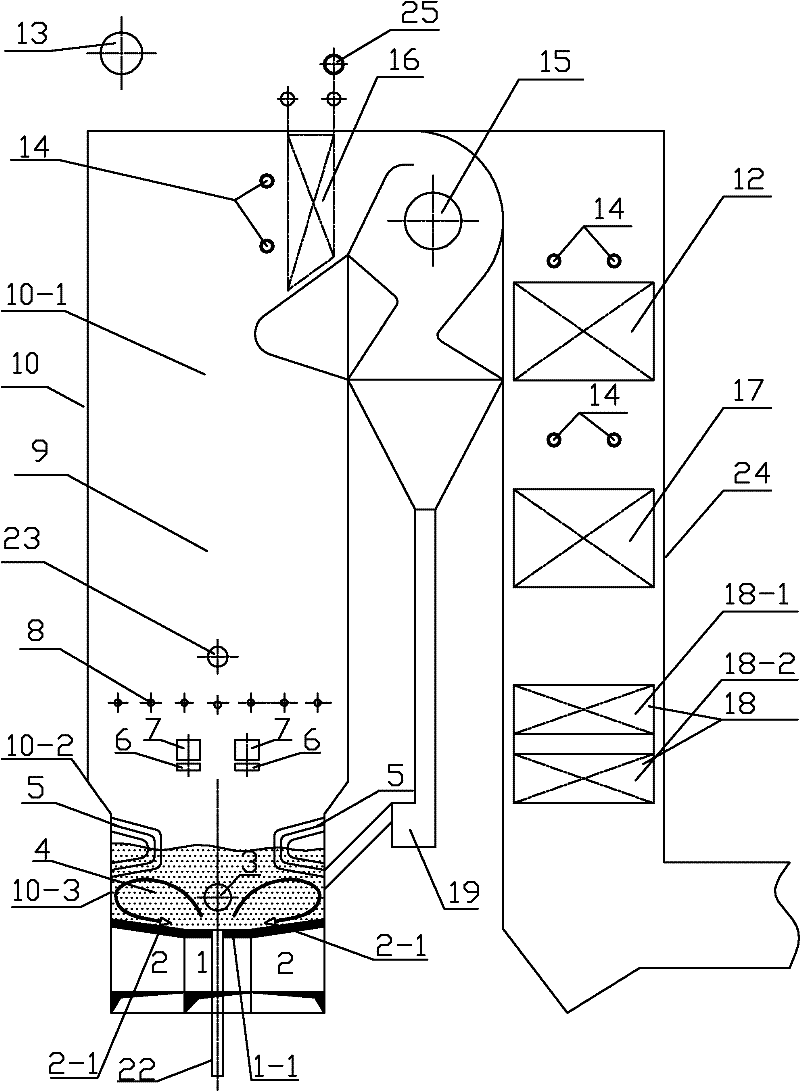

[0033] Specific implementation manner two: such as image 3 As shown, the low-rate biomass circulating fluidized bed boiler of this embodiment eliminates the panel superheater, and arranges the low-temperature convection superheater 16 at the outlet of the furnace and before the medium-temperature steam-cooled cyclone 15, and the high-temperature superheater 12 is placed at the tail. In the upper part of the shaft flue, a desuperheater 25 (water spray or surface desuperheater) is arranged above the low-temperature convection superheater 16. The saturated steam is introduced from the drum 13 into the medium-temperature steam-cooled cyclone separator 15, and then enters the low-temperature convection superheater 16, the desuperheater 25 and the high-temperature convection superheater 12. The material of the high temperature convection through the heater 12 is TP347H, and the material of the low temperature convection through the heater 16 is 20g (medium temperature and medium pres...

specific Embodiment approach 3

[0034] Specific implementation manner three: such as Figure 1~3 As shown, the combustion method of the low-rate biomass circulating fluidized bed boiler burning biomass fuel described in this embodiment and the first or second embodiment is implemented according to the following steps:

[0035] Step 1: Add bed material with an average particle size of 0.6-0.8 mm from the bed material feeding pipe 23 to the furnace of the furnace body 10;

[0036] Step 2: Adopt the negative pressure feeding method: the biomass fuel is sent to the biomass fuel feed port 7 through the feeder, and the biomass fuel is sucked into the furnace by its own weight and the negative pressure in the furnace. Under the action of the sowing wind, the heavier biomass fuel is swept by the sowing wind during the falling process, and is dispersed in the lower dense phase area 4 to burn, and the fines are blown by the flue gas to the upper dilute phase area 9 to burn;

[0037] Step 3. Use a large furnace cross-section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com