Methane-burning heating boiler

A technology for heating boilers and biogas, applied in lighting and heating equipment, fluid heaters, water heaters, etc., can solve the problems that biogas boilers cannot be used for indoor heating, etc., to prolong the combustion residence time, facilitate burnout, and heat evenly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

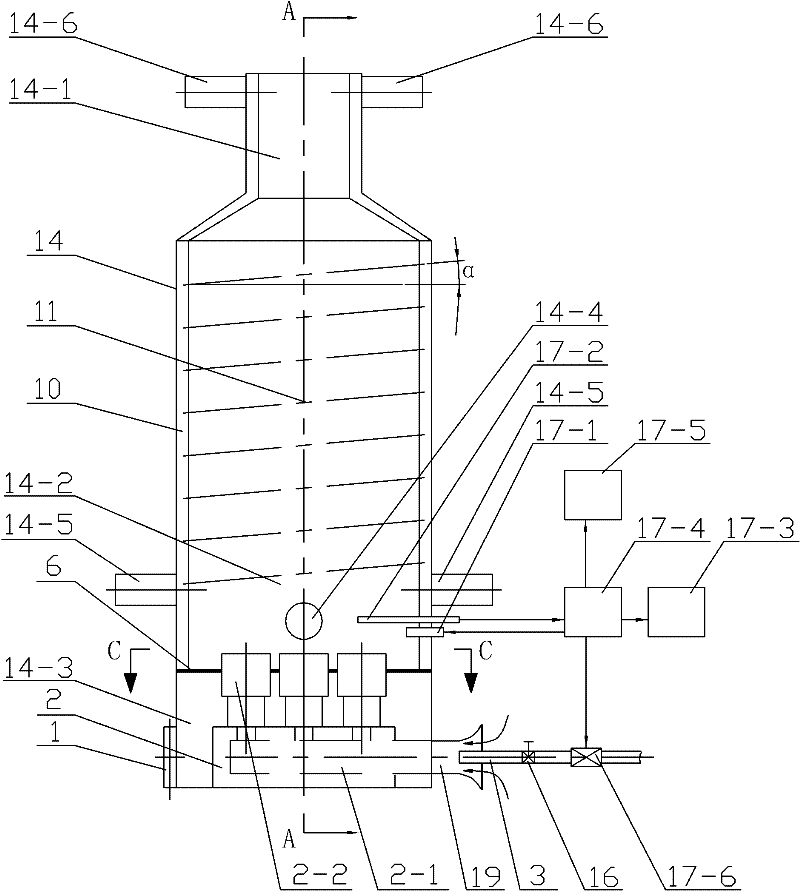

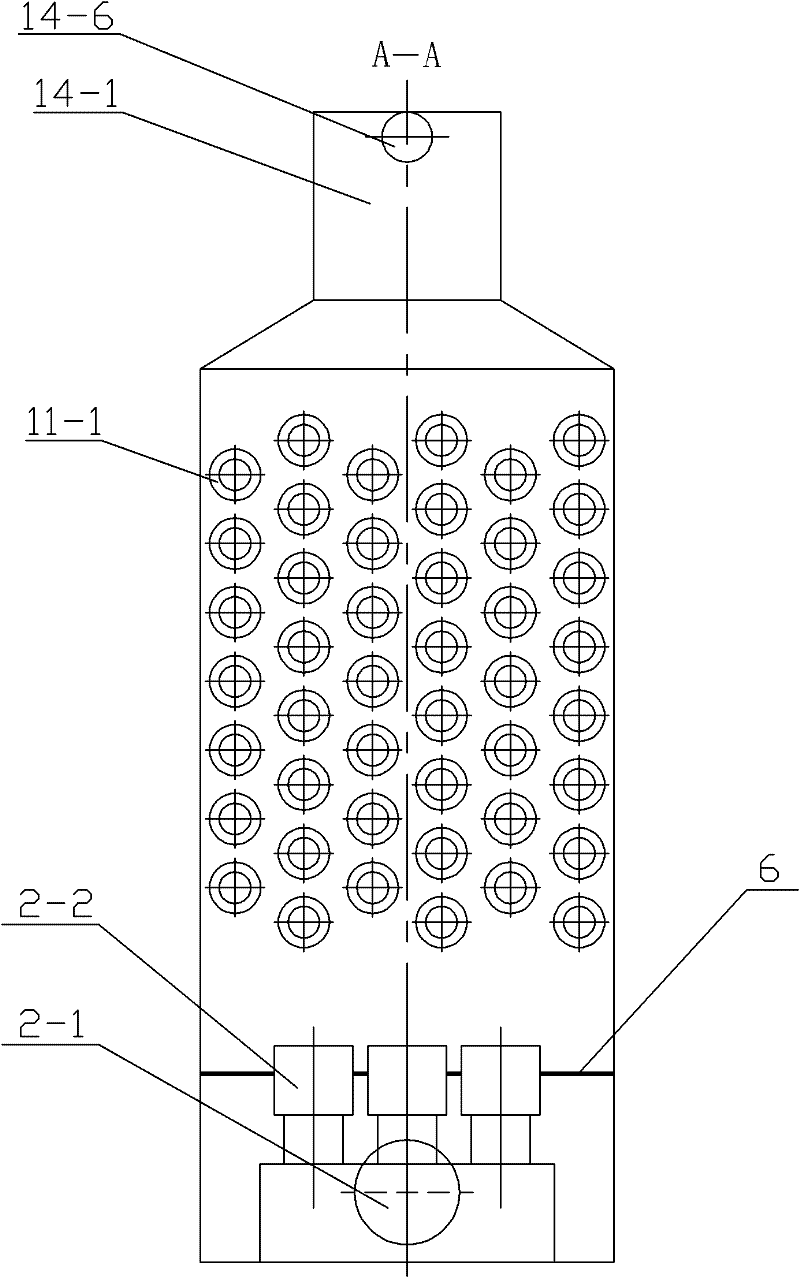

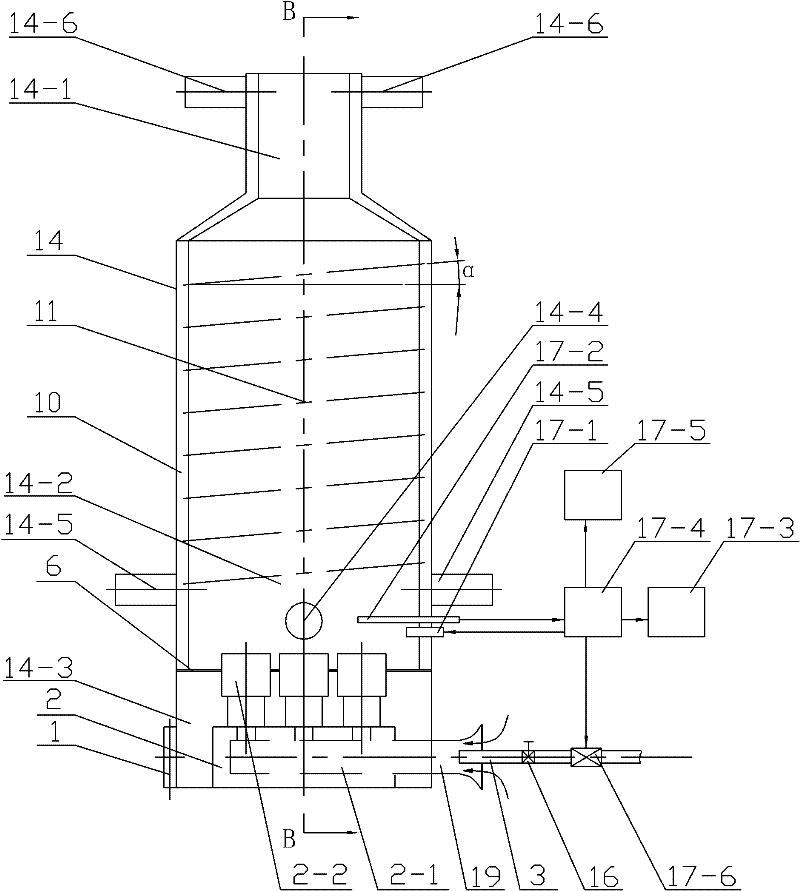

[0008] Embodiment 1: Combining Figure 1-Figure 7 It is explained that the boiler of this embodiment includes a furnace body 14 and a furnace door 1; the boiler also includes a biogas burner 2, a biogas gas transmission pipe 3, an air baffle 6, a heat exchanger 11, a biogas gas transmission pipe valve 16 and a primary air pipe 19; The furnace body 14 is composed of a flue 14-1, a furnace chamber 14-2 and a lower furnace cavity 14-3 in order from top to bottom, and the furnace chamber 14-2 and the lower furnace chamber 14-3 are separated by an air partition 6 Open, the side walls of the flue 14-1 and the furnace 14-2 are water jackets 10 with interlayers, the furnace door is arranged on the side wall of the furnace body 14 and is located in the lower furnace cavity 14-3, and the furnace door 1 is arranged at At the door of the furnace, the air baffle 6 is provided with a fixing hole, the lower end of the biogas burner 2 is arranged on the bottom end surface in the lower furnace...

specific Embodiment approach 2

[0009] Specific implementation mode 2: Combining Figure 1-Figure 4 It is explained that the multi-layer finned tubes 11-1 of the present embodiment are arranged in parallel and inclined, and the included angle α between each layer of finned tubes 11-1 and the horizontal direction is 5°˜10°. The invention draws on the boiler design principle in the design of the heat exchanger, and the finned tubes of the heat exchanger are arranged inclined (5°~10°), which is conducive to the circulation of water in the tubes, and the tubes are provided with fins to greatly increase the heat exchange area and improve the heat utilization. Others are the same as the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation three: combination figure 1 and figure 2 It is explained that the adjacent two layers of the multi-layer finned tubes 11-1 of this embodiment are arranged in a staggered arrangement (for example, each finned tube of the upper layer of finned tubes is located between the adjacent two finned tubes corresponding to the lower layer of finned tubes. space between). With this arrangement, the heat exchange coefficient can be increased, and the heat exchange between the flue gas and the warm water in the finned tubes can be sufficiently achieved. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com