Zhundong coal circulating fluidized bed boiler and control method thereof

A circulating fluidized bed and control method technology, applied in fluidized bed combustion equipment, combustion methods, indirect carbon dioxide emission reduction, etc. Guaranteed reliability, low operating costs, and improved thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

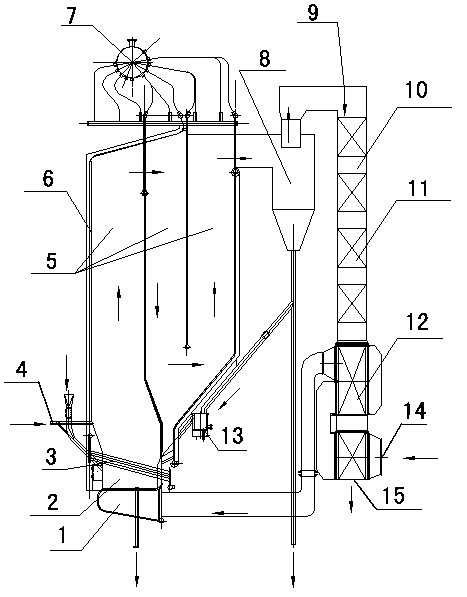

[0028] see figure 1 , the aspect ratio of the furnace 5 is 1.5-2.5, the drum 7 is arranged above the furnace 5, and the secondary air is configured; The inclination angle of the furnace is ≥15°, and there are 2 coal drop ports in the dense-phase positive pressure zone of 5 buried pipes in the furnace, and there are coal sowing air and coal conveying air to prevent coal blocking. The three-pass structure of the furnace includes front, rear, left, right and middle two light-tube film-type wall heating surfaces, that is, the cross-section is the same or similar to the characters "日" and "日", forming a three-pass flue gas channel. It forms a "U"-shaped flue gas channel with the second return, the second return and the third return, and at the same time, it also prolongs the burning residence time of the particles in the furnace. A sanitary combustion belt is laid on the heating surface of the membrane wall on the upper part of the first return furnace, and the combustion temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com