Application of poly-dopamine composite magnetic micro-nano particles in oily sewage treatment

A technology of micro-nano particles and composite magnetism, which is applied in the cross field of micro-nano materials and environmental engineering, can solve the problems of difficult separation and high processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

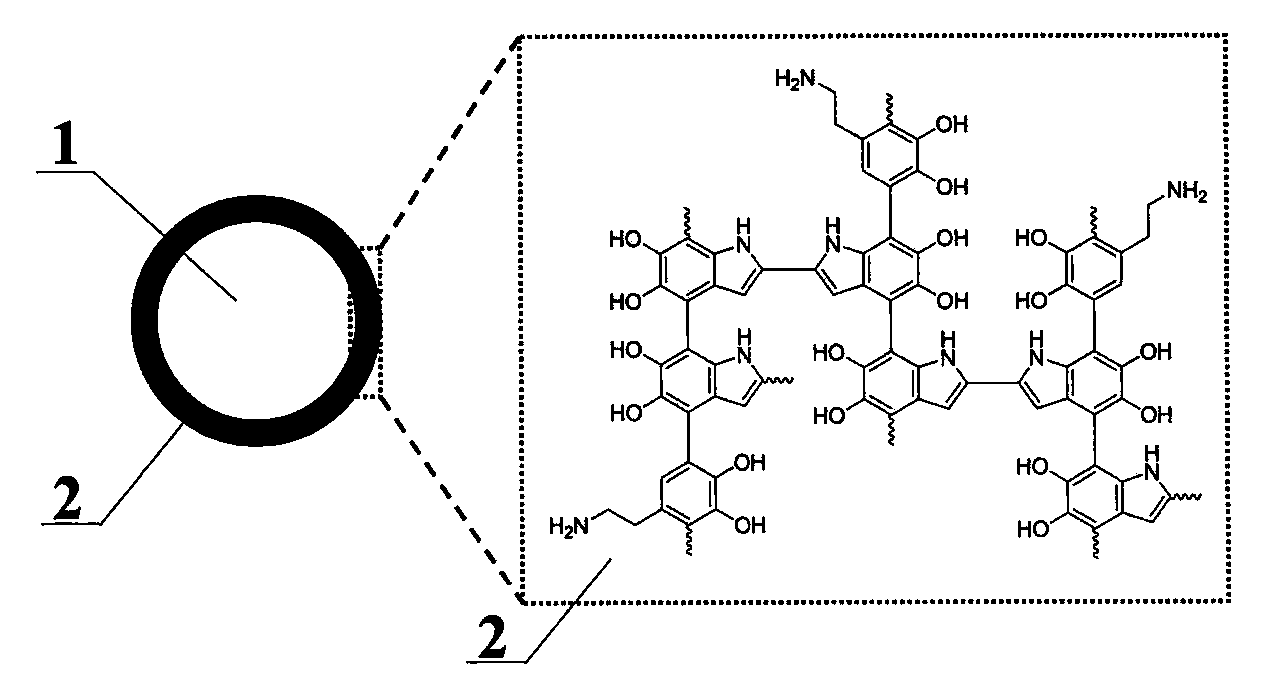

[0027] Example 1. Preparation of a layer of polydopamine surface modified biomimetic composite magnetic ferric oxide micro-nano particles:

[0028] At room temperature of 20°C, add 50mL of distilled water, 0.40g of ferrous chloride tetrahydrate, 1.08g of ferric chloride nonahydrate and 0.1g of dopamine hydrochloride into a 100mL three-necked round-bottomed flask in turn, stir until fully dissolved, and slowly 1M sodium hydroxide aqueous solution was added dropwise to maintain the pH of the reaction system between 9.0-9.5, and reacted for 2 hours to obtain a mixed solution. Then quickly add 5mL of 2M sodium hydroxide aqueous solution, and then raise the temperature to 75°C under the protection of nitrogen, and react for 1 hour to obtain a layer of polydopamine surface modified biomimetic composite magnetic ferric oxide micro-nanoparticles.

Embodiment 2

[0029] Example 2. Preparation of a layer of polydopamine surface modified biomimetic composite magnetic ferric oxide micro-nano particles:

[0030] At room temperature of 25°C, add 50mL of distilled water, 0.52g of ferrous sulfate heptahydrate and 1.616g of ferric chloride nonahydrate into a 100mL three-neck round bottom flask successively, stir until fully dissolved, and slowly add 5mL of 1M sodium hydroxide dropwise and a mixed aqueous solution of 0.08g dopamine to maintain the pH of the reaction system between 9.0-9.5, react for 2 hours to obtain a mixed solution; then quickly add 5mL of 2M sodium hydroxide aqueous solution, and then raise the temperature to 85°C for 1 hour under the protection of nitrogen , that is to obtain a layer of polydopamine surface modified biomimetic composite magnetic ferric oxide micro-nano particles.

Embodiment 3

[0031] Example 3. Preparation of a layer of polydopamine surface modified biomimetic composite magnetic ferric oxide micro-nano particles:

[0032] Under the conditions of constant stirring and nitrogen protection, 30 mL of distilled water, 20 mL of 1M sodium hydroxide, and 0.1 g of L-dopamine were successively added to a 100 mL three-necked round-bottomed flask, and the temperature was raised to 80 °C, and then 0.52 g of ferrous sulfate heptahydrate was slowly added dropwise. and 1.93g of ammonium ferric sulfate dodecahydrate mixed aqueous solution, continue to react for 1h after the dropwise addition, then lower to room temperature 20-30°C, and stop the nitrogen protection, maintain the pH of the reaction system = 8.5, react for 2h, and obtain a layer Biomimetic composite magnetic Fe3O4 micro-nanoparticles modified by polydopamine surface modification.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com