Preparing method of copper-base electric contact material enhanced by in-situ grown graphene

An electrical contact material, in-situ growth technology, applied in metal material coating process, metal processing equipment, gaseous chemical plating, etc., can solve the problems of high price, low cost performance, uneven dispersion of graphene, etc., to avoid agglomeration , performance improvement, quality assurance and uniform dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

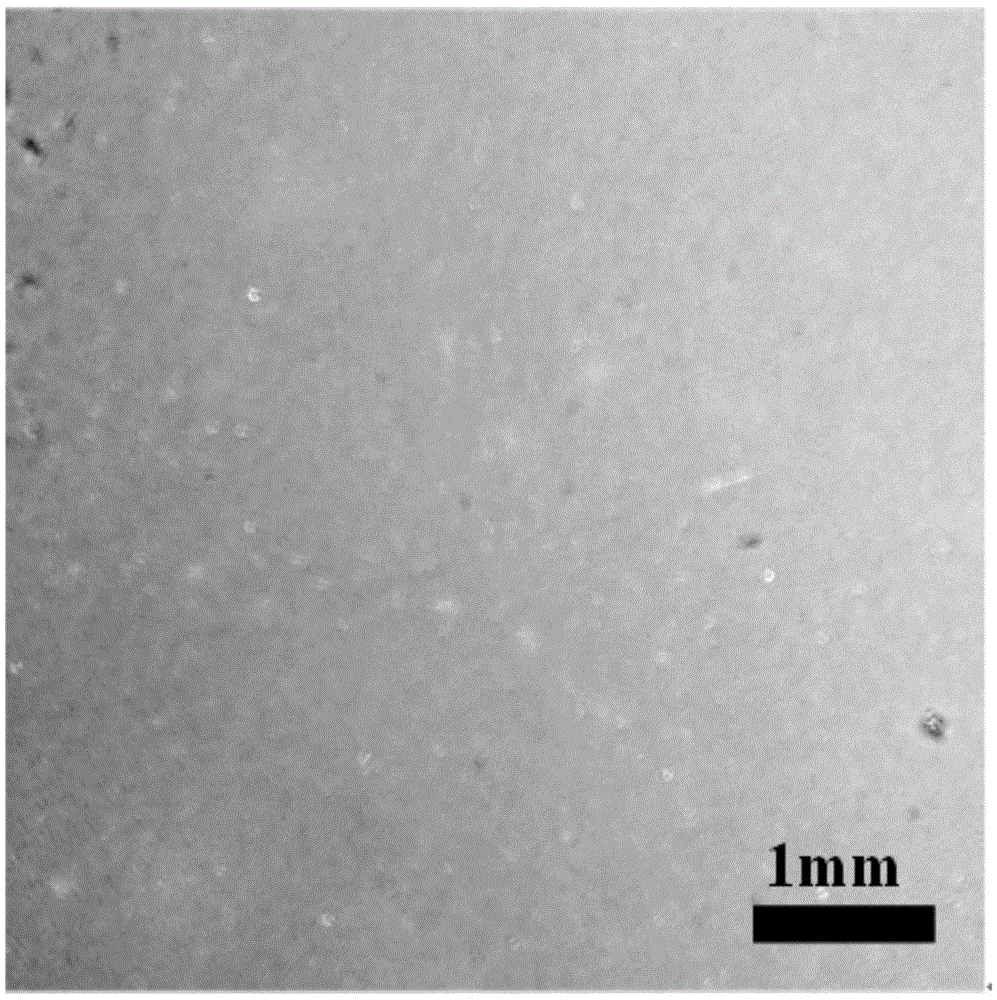

Image

Examples

specific Embodiment approach 1

[0016] Specific Embodiment 1: The preparation method of a kind of in-situ growth graphene reinforced copper-based electrical contact material described in this embodiment is specifically carried out according to the following steps:

[0017] 1. Copper powder is placed in the plasma-enhanced chemical vapor deposition vacuum device. After vacuuming, hydrogen gas is fed into the plasma-enhanced chemical vapor deposition vacuum device with a gas flow rate of 30 sccm, and the pressure in the plasma-enhanced chemical vapor deposition vacuum device is adjusted to be 200Pa. Under a hydrogen atmosphere, raise the temperature to 400°C-800°C, and anneal and hold for 15min-25min at a temperature of 400°C-800°C;

[0018] 2. Introduce methane gas and argon gas, adjust the flow rate of methane gas to 1sccm~20sccm, adjust the flow rate of argon gas to 100sccm, adjust the pressure in the plasma-enhanced chemical vapor deposition vacuum device to 200Pa~1000Pa, and then set the RF power to 50W~ ...

specific Embodiment approach 2

[0023] Embodiment 2: This embodiment differs from Embodiment 1 in that: the particle size of the copper powder in step 1 is 100 nm˜100 μm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the purity of the copper powder in step 1 is more than 99% by mass. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com