Silicon dioxide carbon composite negative electrode material, modified silicon dioxide carbon composite negative electrode material and preparation methods and application of silicon dioxide carbon composite negative electrode material and modified silicon dioxide carbon composite negative electrode material

A technology of silicon dioxide and negative electrode materials, applied in nanotechnology for materials and surface science, battery electrodes, secondary batteries, etc., can solve the problems of volume expansion and harsh synthesis conditions, and achieve the reduction of volume expansion and electrochemical Improved performance and strong controllability of preparation parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a method for preparing a silicon dioxide-carbon composite negative electrode material, wherein the method comprises:

[0028] (1) in the presence of a solvent, halloysite is mixed with an organic carbon source, and then the solvent is removed to obtain a solid product;

[0029] (2) Calcining the solid product under an inert atmosphere.

[0030] The present invention adopts relatively common halloysite as a silicon dioxide raw material to combine with carbon in an organic carbon source to produce a composite structure. The preparation method has simple process and common raw materials.

[0031] As long as the above requirements are met, the purpose of the present invention can be achieved, but in order to further improve the electrochemical performance of the obtained silicon dioxide carbon composite negative electrode material, it is preferred that the method also includes: combining the halloysite with the organic carbon source Halloysite is pre...

Embodiment approach

[0033] According to a preferred embodiment of the present invention, the pre-calcination conditions include: the pre-calcination temperature is 300-900°C, the pre-calcination time is 1-5h, preferably the pre-calcination temperature is 550-800°C, and more preferably the pre-calcination is at It is carried out under an air atmosphere, and it is further preferred that the heating rate of the pre-calcination process from normal temperature to the pre-calcination temperature is 2-5° C. / min.

[0034] The normal temperature mentioned in the present invention refers to 10-40°C.

[0035] The halloysite pre-calcination process can remove the crystal water in the halloysite, which is more conducive to improving the discharge specific capacity and cycle stability of the prepared silicon dioxide carbon composite negative electrode material.

[0036] According to a preferred embodiment of the present invention, the product obtained after pre-calcination is mixed and contacted with an acid, ...

Embodiment 1

[0082] This example is used to illustrate the silicon dioxide carbon composite negative electrode material and its preparation method of the present invention.

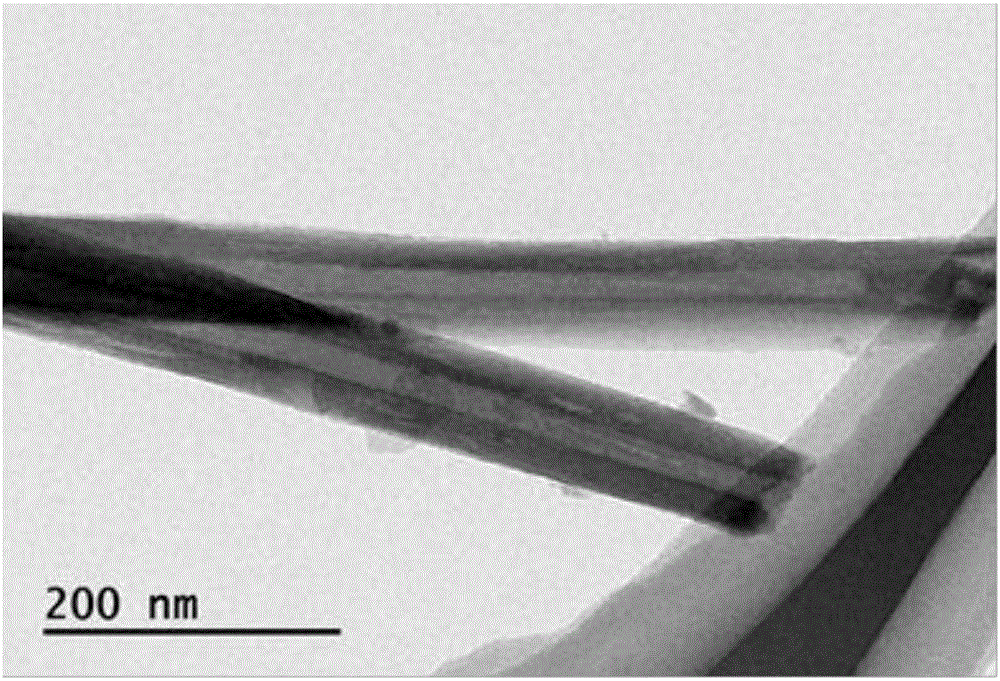

[0083] (1) After roasting 10g of natural halloysite at 800°C (heating rate: 5°C / min) in an air atmosphere for 2h, place it in 100ml of hydrochloric acid with a concentration of 6mol / L, and place it in a 100°C oil bath Stir at constant temperature for 6 hours, centrifuge, wash with water to pH = 7, and then dry at 100°C for 3 hours. The TEM image of the obtained product is shown in figure 1 shown;

[0084] (2) Add the product obtained in step (1) and sucrose into deionized water in a mass ratio of 1:1 for mixing, and dry at 60° C. for 4 hours;

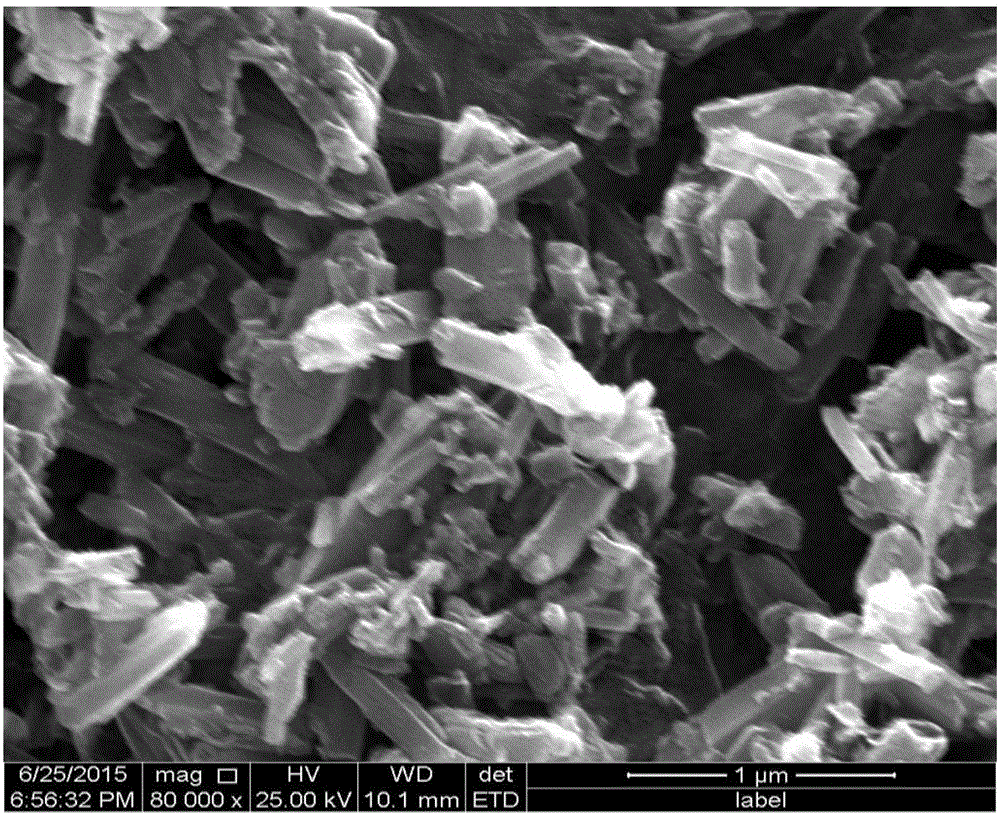

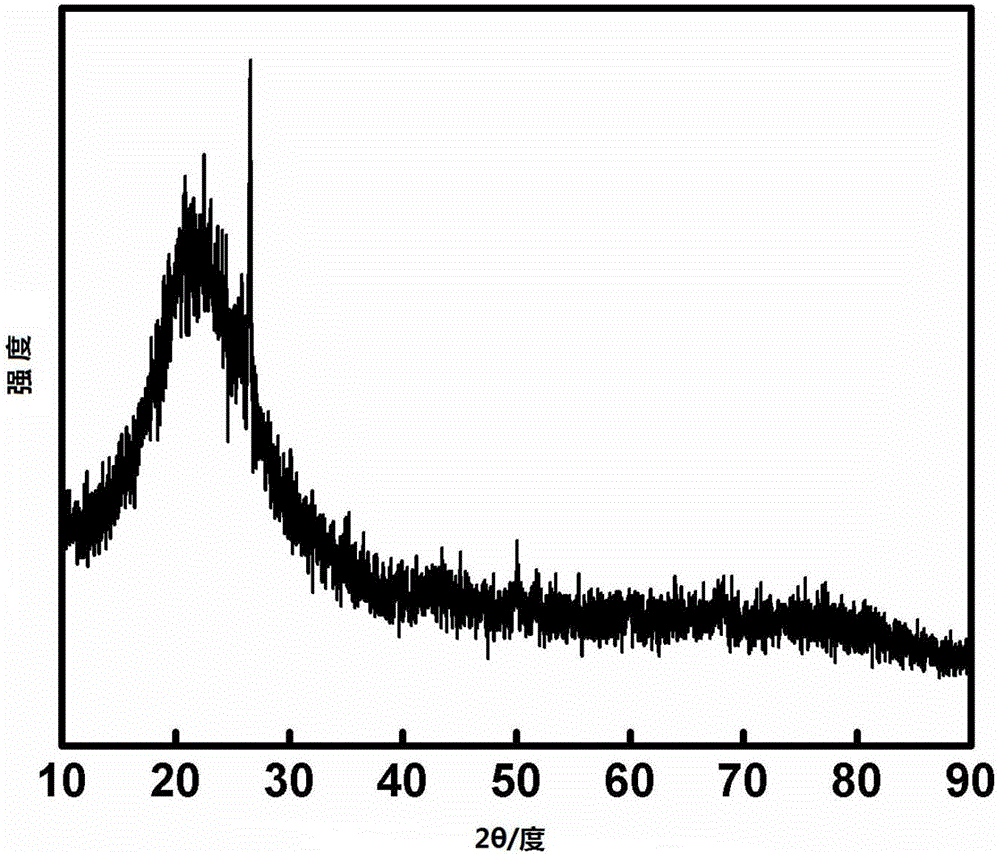

[0085] (3) Calcining the product obtained in step (2) under an argon atmosphere, the conditions of the calcination include: the calcination temperature is 900°C, the calcination time is 3h, and the heating rate is 5°C / min. After being cooled to room temperature, the silicon d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com