Method for preparing halloysite/epoxy composite coating capable of controlling release of corrosion inhibitor by pH response

A composite coating and controlled release technology, applied in the field of nanocomposite preparation, can solve the problems of unsatisfactory HNTs dispersion, reduced coating corrosion resistance, HNTs agglomeration, etc., and achieves low cost, improved thermal stability, and preparation process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

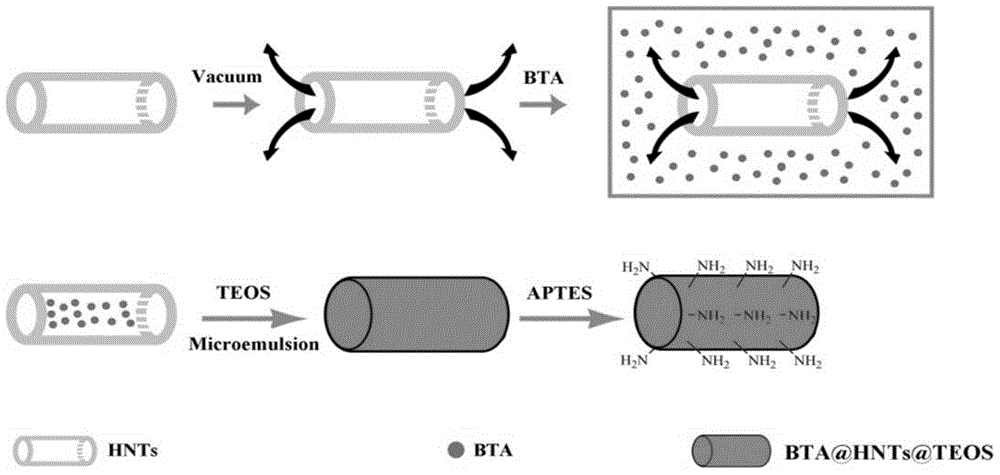

[0021] Preparation method of halloysite / epoxy composite coating with pH-responsive controlled release corrosion inhibitor, see attached figure 1 , including the following steps:

[0022] (1) Loading corrosion inhibitor: Mix 2g of HNTs and 40mL of benzotriazole solution (BTA) with a concentration of 80mg / mL (BTA), and disperse ultrasonically for 30min to obtain a suspension, then place the suspension in a rotary evaporator, Rotate at 80r / min, under the conditions of 10MPa, vacuumize for 2h, open the valve to maintain normal pressure for 2min;

[0023] (2) Encapsulation corrosion inhibitor: Add 10mL distilled water and 0.5mL 25% ammonia water to the concentrated suspension, then add 0.5mL tetraethyl orthosilicate (TEOS) dropwise, react at room temperature for 12 hours, and then add dropwise Add 0.5mLTEOS, react for 12h;

[0024] (3) Modified halloysite nanotubes: After the reaction in step (2), add 1 mL of 3-aminopropyltriethoxysilane (APTES) dropwise, react at room temperatur...

Embodiment 2

[0030] Embodiment 2 comparative experiment

[0031] There is long-acting anticorrosion coating, and its preparation method comprises the following steps:

[0032] (1) Loading corrosion inhibitor: mix 2g HNTs with saturated benzotriazole acetone solution (benzotriazole 5g, acetone 50mL), ultrasonically disperse for 20min to obtain a suspension, and then place the suspension in a vacuum bottle , Use a vacuum pump to evacuate under the condition of 10MPa, turn off the vacuum pump after 3 minutes, keep the vacuum state, and then place it under normal pressure after 3 hours, repeat the above operation 3 times;

[0033] (2) The HNTs loaded with corrosion inhibitors were separated by a centrifuge, and then the corrosion inhibitors adsorbed on the surface were washed with deionized water, and dried at 60°C for 5 hours;

[0034] (3) The substance in the step (2) is dispersed in the acrylic latex paint to obtain a long-acting anti-corrosion coating.

[0035] Disadvantages: 1) The two ...

Embodiment 3

[0037] Embodiment 3 comparative experiment

[0038] There is long-acting anticorrosion coating, and its preparation method comprises the following steps:

[0039] (1) Loading corrosion inhibitor: Mix 2g HNTs and 80mg / L ethanol solution of benzotriazole (benzotriazole 4mg, ethanol 50mL), and ultrasonically disperse for 20min to obtain a white suspension, then place the suspension in In the vacuum bottle, use a vacuum pump to evacuate under the condition of 10MPa, turn off the vacuum pump after 3 minutes, keep the vacuum state for 1-5 hours, and then place it under normal pressure, repeat the above operation 3 times;

[0040](2) The HNTs loaded with corrosion inhibitors were separated by a centrifuge, and then the corrosion inhibitors adsorbed on the surface were washed with deionized water, and dried at 60°C for 5 hours;

[0041] (3) Place the HNTs of the loaded corrosion inhibitor in step (2) in copper sulfate aqueous solution (0.5-5g / L) of different concentrations, form a BT...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com