Polyurethane-amino resin modified waterborne alkyd resin and preparation and application thereof

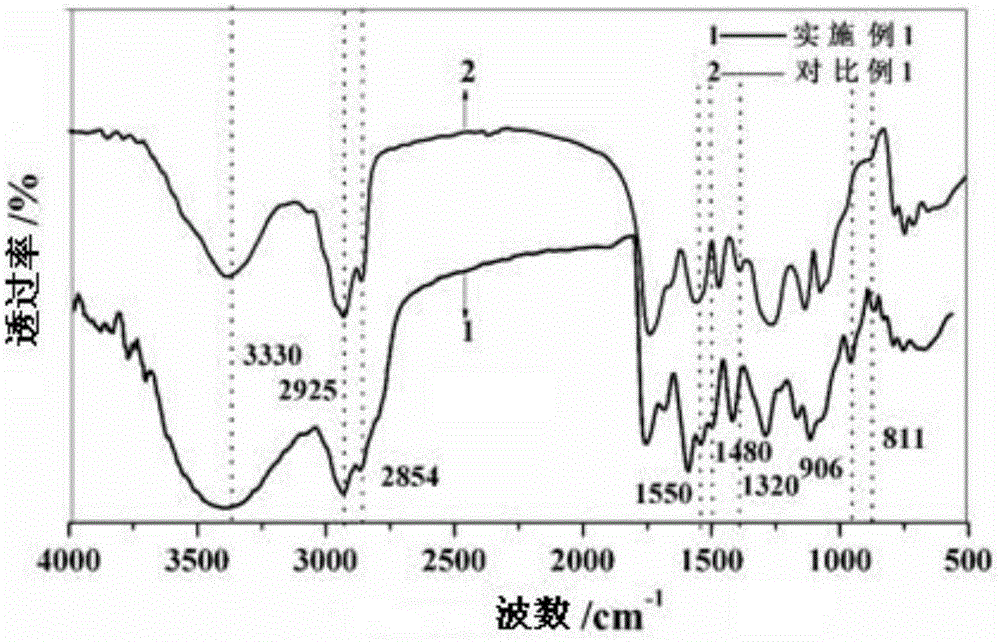

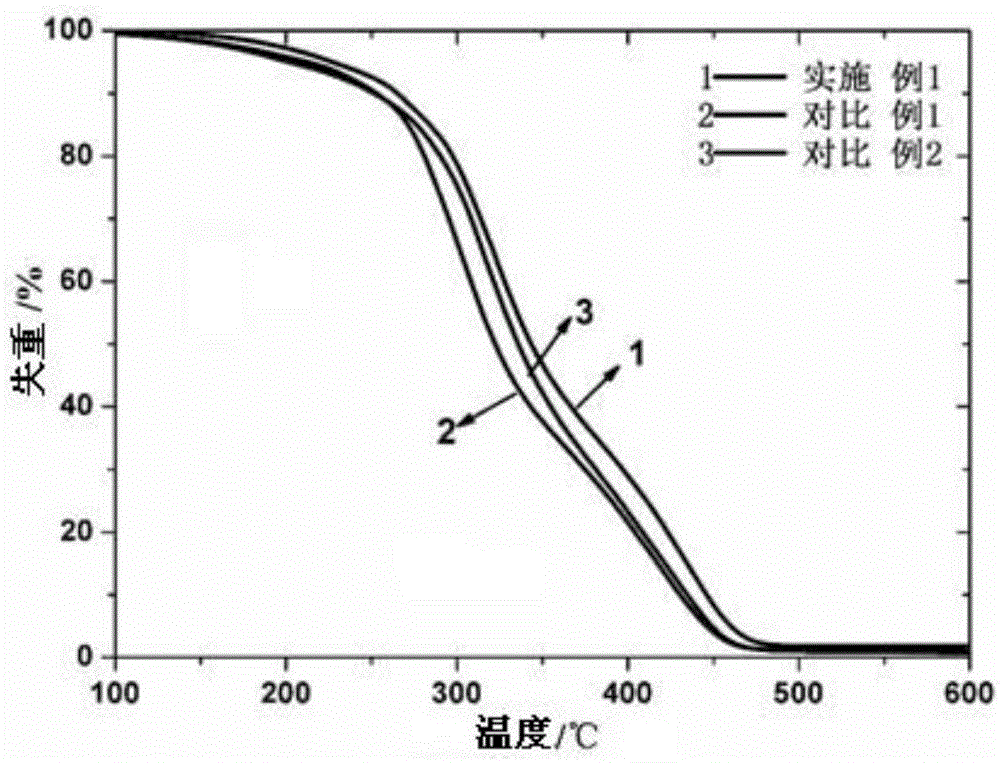

A technology of amino resin modification and water-based alkyd resin, which is applied in the field of coatings. It can solve the problems of poor storage stability, slow drying of paint films, and restrictions on amino baking varnishes. It achieves high formula adjustability, reduced surface energy, and increased The effect of hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

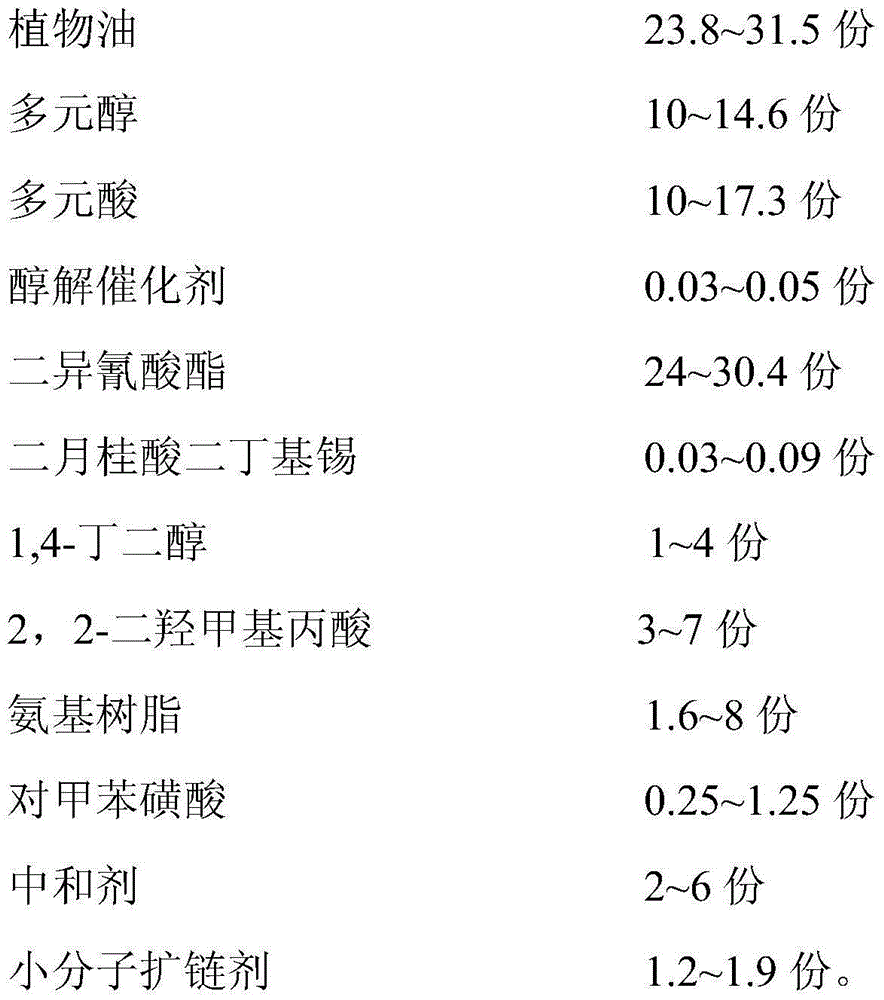

[0064] (1) Alcoholysis: When a condensation tube, a thermometer, an agitator are installed and there is nitrogen (N 2 ) protected four-neck flask, add 31.5g dehydrated castor oil and 14.6g trimethylolpropane, slowly heat up to 120°C, add 0.04g lithium hydroxide, then slowly raise the temperature to 240°C, and keep it warm for 1 hour; When the tolerance of the ethanol solution with a mass concentration of 87% reaches 1:3, start to cool down;

[0065] (2) Esterification: Cool down to 140°C, add 11.5g of phthalic anhydride and 5.8g of isophthalic acid, add 10.5g of xylene as a reflux solvent to remove the water generated by esterification, and continue heating at 180°C Keep it warm for 1 hour, then raise the temperature from 15°C to 240°C every 20 minutes, then keep it warm for 1 hour; when the acid value of the system is about 10mgKOH﹒ g -1 When, stop heating, begin to cool down, make alkyd polyol prepolymer;

[0066] (3) Polyurethane modification: cool down to 75°C, add 30.4...

Embodiment 2

[0074] (1) Alcoholysis: When a condensation tube, a thermometer, an agitator are installed and there is nitrogen (N 2 ) protected four-neck flask, add 23.8g linseed oil and 10.8g trimethylolpropane, when the temperature is slowly raised to 120°C, add 0.03g lithium hydroxide, then slowly raise the temperature to 240°C, and keep the temperature for 1 hour; When the tolerance of the ethanol solution with a mass concentration of 87% reaches 1:3, start to cool down;

[0075] (2) Esterification: When the temperature is lowered to 140°C, add 10.2g of phthalic anhydride and 8g of xylene as a reflux solvent to remove the water generated by esterification, continue heating, and keep warm at 180°C for 1 hour, and then every 20min After raising the temperature from 15°C to 240°C, keep it warm for 1 hour; when the acid value of the system is about 10mgKOH﹒ g -1 When, stop heating, begin to cool down, make alkyd polyol prepolymer;

[0076] (3) Polyurethane modification: when the temperat...

Embodiment 3

[0082] (1) Alcoholysis: When a condensation tube, a thermometer, an agitator are installed and there is nitrogen (N 2 ) protected four-neck flask, add 23.8g linseed oil and 10.8g trimethylolpropane, when the temperature is slowly raised to 120°C, add 0.03g lithium hydroxide, then slowly raise the temperature to 240°C, and keep the temperature for 1 hour; When the tolerance of the ethanol solution with a mass concentration of 87% reaches 1:3, start to cool down;

[0083] (2) Esterification: When the temperature is lowered to 140°C, add 10.2g of phthalic anhydride and 8g of xylene as a reflux solvent to remove the water generated by esterification, continue heating, and keep warm at 180°C for 1 hour, and then every 20min After raising the temperature from 15°C to 240°C, keep it warm for 1 hour; when the acid value of the system is about 10mgKOH﹒ g -1 When, stop heating, begin to cool down, make alkyd polyol prepolymer;

[0084] (3) Polyurethane modification: when the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com