Epoxy modified high-temperature-resistant anticorrosive paint

An anti-corrosion coating and epoxy modification technology, applied in the field of coatings, can solve the problems of high dosage, unsightly surface, low temperature resistance, etc. Good heat exchange performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

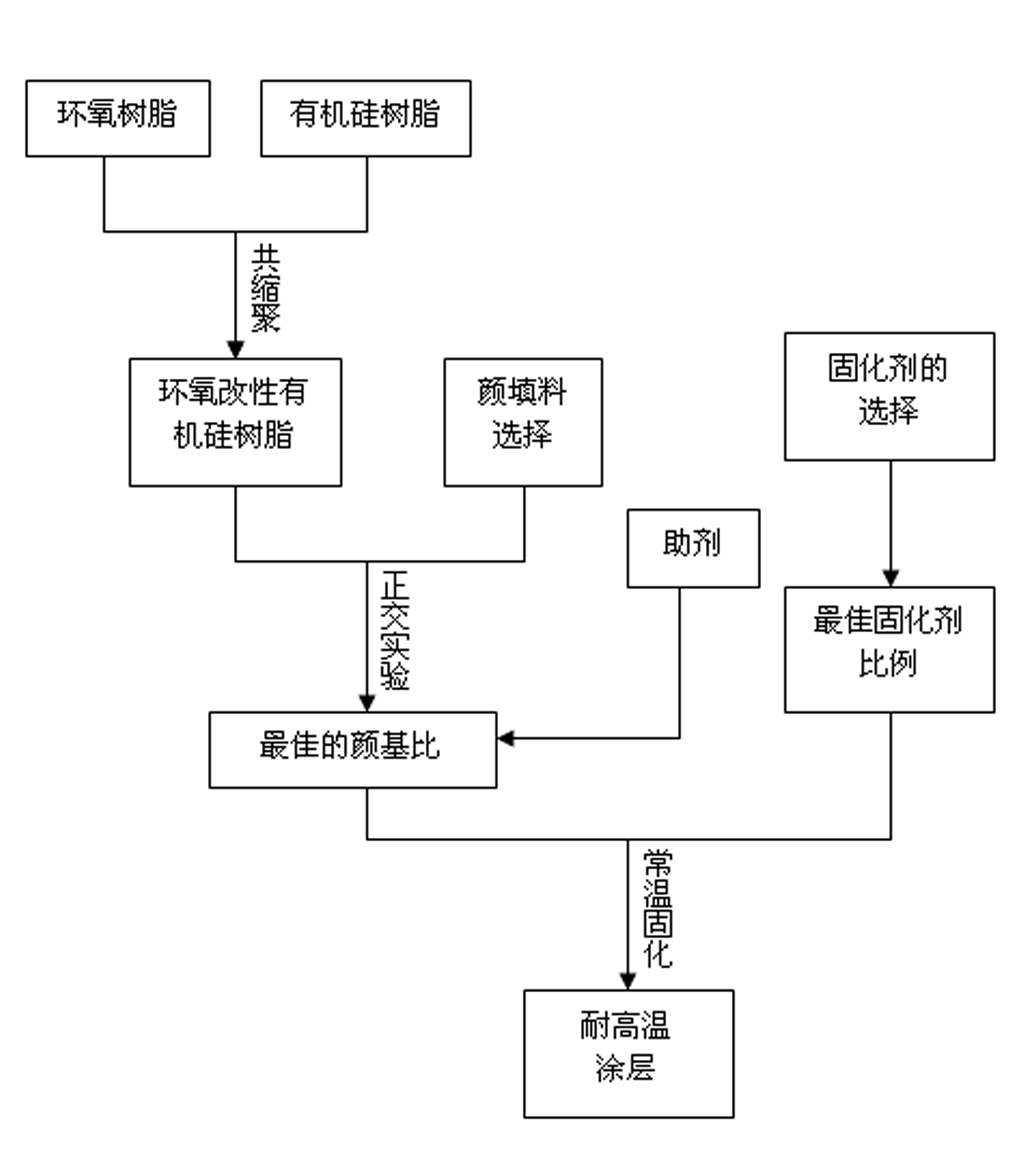

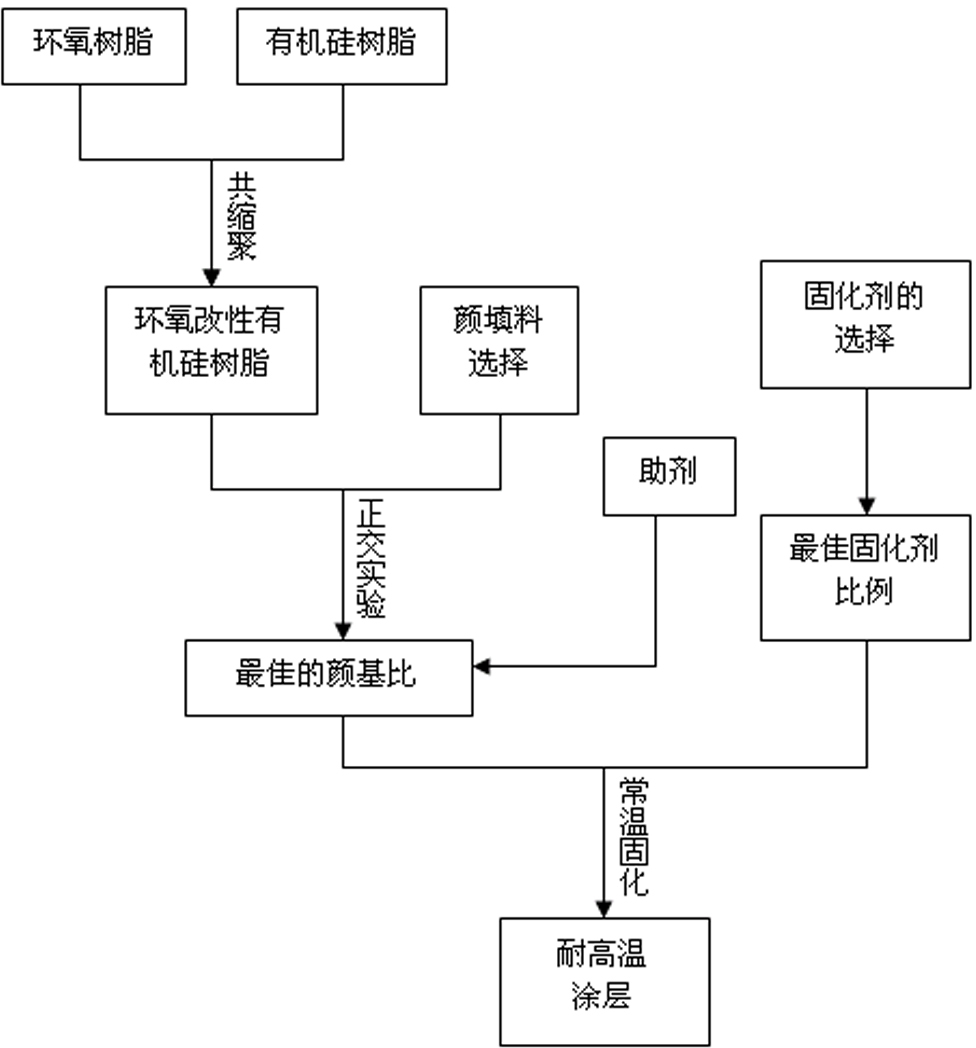

Method used

Image

Examples

Embodiment 1

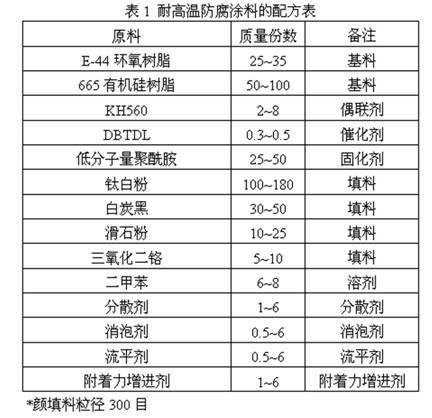

[0015] Pour 25g of E-44 type epoxy resin and 50g of 665 type silicone resin into a three-necked bottle equipped with a condensing device and a stirrer, start stirring, and after mixing evenly, add 2~3g of coupling agent KH-560 of resin system quality, Then add the catalyst DBTDL with 1-2% of the mass of the coupling agent and raise the temperature to 120-130°C, and react at a constant temperature for 6 hours under constant stirring to prepare the base material for high-temperature resistant anti-corrosion coatings.

[0016] Add 100g of titanium dioxide, 30g of white carbon black, 10g of talcum powder and 5g of chromium trioxide that have been ball-milled through a 300-mesh sieve to the resin base prepared above, and add a solvent with a mass fraction of 5-20% of the system Xylene makes it moderately viscous and suitable for brushing. Add 3% dispersant of pigment and filler mass, 2% defoamer of resin matrix mass, 3% system mass anti-crater leveling agent and 5% system mass adhe...

Embodiment 2

[0019] Pour 25g of E-44 type epoxy resin and 75g of 665 type silicone resin into a three-necked bottle equipped with a condensing device and a stirrer, and prepare a base material for a high temperature resistant anti-corrosion coating according to the method in Example 1.

[0020] Add 150g of titanium dioxide, 40g of white carbon black, 20g of talcum powder and 10g of chromium trioxide that have been ball-milled and passed through a 300-mesh sieve to the above-prepared resin base, and add a solvent with a mass fraction of 5-20% of the system Xylene makes it moderately viscous and suitable for brushing. Add 3% dispersant of pigment and filler mass, 2% defoamer of resin matrix mass, 3% system mass anti-crater leveling agent and 5% system mass adhesion promoter to the above mixture, and stir well evenly.

[0021] Finally, 25 g of low-molecular-weight polyamide was added as a curing agent, and cured at room temperature to form a film. The resulting coating has a temperature resi...

Embodiment 3

[0023] Pour 25g of E-44 type epoxy resin and 100g of 665 type silicone resin into a three-necked bottle equipped with a condensing device and a stirrer, start stirring, and after mixing evenly, prepare a base material for a high temperature resistant anti-corrosion coating according to the method in Example 1.

[0024] Add 180g of titanium dioxide, 50g of white carbon black, 25g of talcum powder, and 10g of chromium trioxide that have been ball-milled through a 300-mesh sieve to the resin base prepared above, and add a solvent with a mass fraction of 5-20% of the system Xylene makes it moderately viscous and suitable for brushing. Add 2% of pigment and filler mass dispersant, 1% resin matrix mass of defoamer, system mass of 2% of anti-crater leveling agent and system mass of 1% of adhesion promoter to the above mixture, and stir well.

[0025] Finally, 25 g of low-molecular-weight polyamide was added as a curing agent, and cured at room temperature to form a film. The resulti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com