Rare-earth polyurethane high-polymer composite luminescent material and preparation method thereof

A technology of polyurethane and luminescent materials, applied in luminescent materials, chemical instruments and methods, etc., to achieve the effects of mild conditions, convenient and simple product processing, and easy control of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

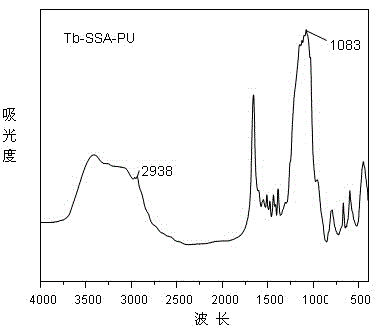

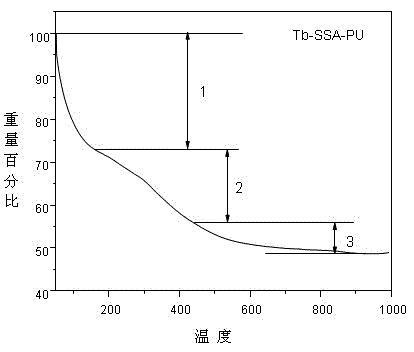

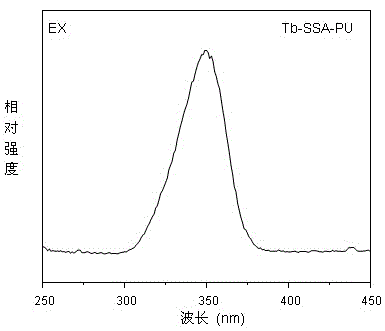

Image

Examples

Embodiment 1

[0039] The synthesis of a rare-earth polyurethane polymer composite luminescent material specifically includes the following steps:

[0040] (1) Chemical modification of carboxylic acid organic ligands containing hydroxyl groups

[0041] Weigh 0.2182g of sulfosalicylic acid (SSA), dissolve it in 20mL of tetrahydrofuran, put the solution into a three-necked flask, then weigh 0.0675g of thionyl chloride, drop it into the flask, and put it in a nitrogen atmosphere. After the reaction temperature is 65°C and the reaction time is 3 hours, 0.2214g of silane coupling agent APTES is added, and the reaction lasts for 6 hours. Finally, the solution after the reaction is separated and purified by a rotary evaporator to obtain a yellow oily liquid that is the compound containing hydroxyl The hydroxyl-containing carboxylic acid organic ligand precursor SSA-Si after the chemical modification of the carboxylic acid organic ligand sulfosalicylic acid;

[0042] (2) Preparation of binary rare ...

Embodiment 2

[0051] A rare earth polyurethane polymer composite luminescent material, specifically comprising the following preparation steps:

[0052] (1) Chemical modification of carboxylic acid organic ligands containing hydroxyl groups

[0053] Weigh 0.153g of 2-amino-5-hydroxybenzoic acid (AHBA), dissolve it in 15mL of DMF, put the solution into a three-necked flask, add 0.241g of silane coupling agent 3-chloropropyltriethoxysilane, in Under a nitrogen atmosphere, the reaction temperature was 153°C for 6 hours. Finally, the solution after the reaction was separated and purified by a rotary evaporator, and the obtained liquid was the carboxylic acid organic ligand 2-amino-5- Hydroxybenzoic acid chemically modified carboxylic acid organic ligand precursor AHBA-Si containing hydroxyl;

[0054] (2) Preparation of binary rare earth carboxylic acid hybrid materials

[0055] The hydroxyl-containing carboxylic acid organic ligand precursor AHBA-Si obtained in step (1) was dissolved in 15 mL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com