Preparation method of transition metal microcrystal-doped chalcogenide glass composite material

A composite material and transition metal technology, applied in the field of transition metal microcrystalline doped chalcogenide glass composite material and its preparation, can solve the problem of no mid-infrared laser gain medium material and the like, achieve stable thermal performance, high luminous quantum efficiency, The effect of excellent optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

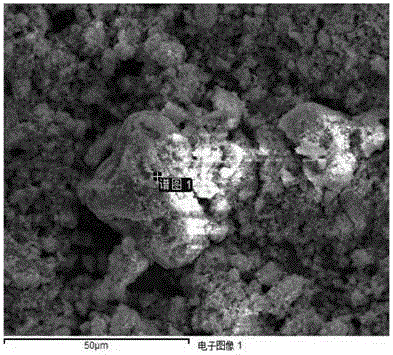

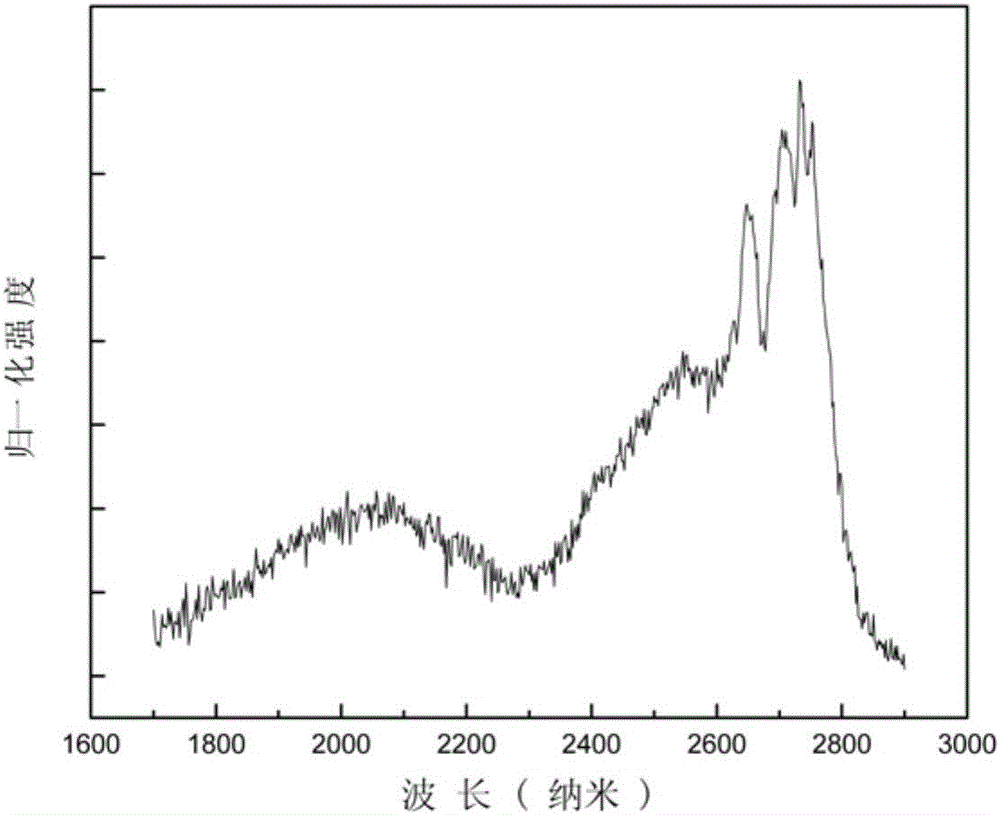

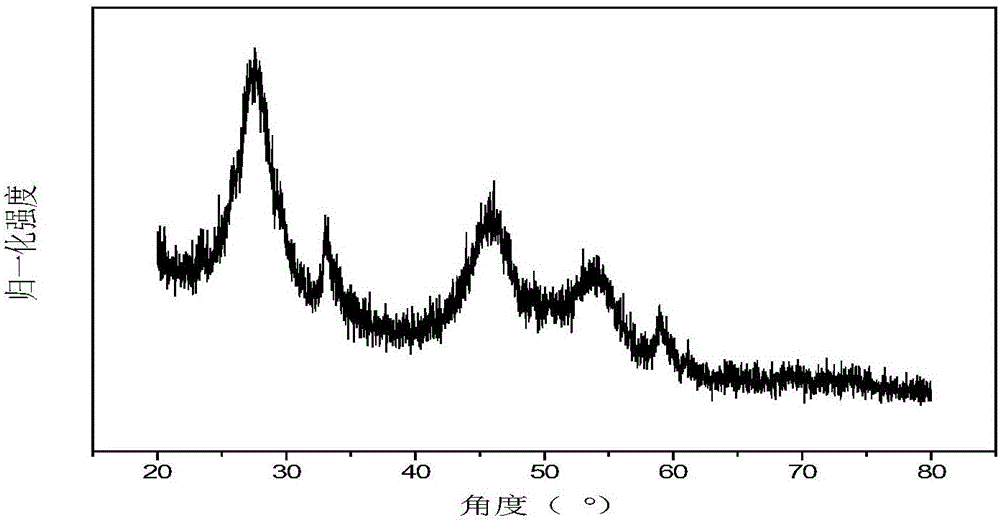

[0031] Example 1: Preparation of transition metal crystallites doped chalcogenide glass composites

[0032] With Co 2+ :ZnSe doped As 2 S 3 Taking glass as an example, the following steps are involved:

[0033] (1) The particle size of the CoSe powder is selected to be 3 μm, and the mass ratio is 2%. The particle size of the ZnSe powder is 1000 μm, and the mass ratio is 98%. Put the CoSe and ZnSe powders into a ball mill and stir for 12 hours to make the powders fully mixed evenly. Put the uniformly mixed powder into a quartz tube, place it in a furnace, and keep it at 900°C for 96 hours to obtain Co 2+ : ZnSe material.

[0034] (2) will Co 2+ :ZnSe material and As 2 S 3 The glass is put into a ball mill, where Co 2+ : The mass ratio of ZnSe material is 10%, and it is ground for 72 hours to prepare a uniformly mixed powder with a particle size of about 1 μm.

[0035] (3) Put the above mixed powder in a quartz tube and vacuumize to 1×10 -3 Pa, sealed, put into the m...

Embodiment 2

[0037] Example 2: Preparation of transition metal crystallites doped chalcogenide glass composites

[0038] in Cr 2+ :ZnSe doped As 2 S 3 Taking glass as an example, the following steps are involved:

[0039] (1) The particle size of the CrSe powder is selected to be 1 μm, and the mass ratio is 4%. The particle size of the ZnSe powder is 1000 μm, and the mass ratio is 96%. Put the CrSe and ZnSe powders into a ball mill and stir for 12 hours to make the powders fully mixed evenly. Put the uniformly mixed powder into a quartz tube, place it in a furnace, and keep it at 1100°C for 132 hours to obtain Cr 2+ : ZnSe material.

[0040] (2) Add Cr 2+ :ZnSe material and As 2 S 3 The glass is put into a ball mill, where Cr 2+ : The mass ratio of ZnSe material is 1%, and it is ground for 72 hours to prepare a uniformly mixed powder with a particle size of about 1 μm.

[0041] (3) Put the above mixed powder in a quartz tube and vacuumize to 1×10 -3 Pa, sealed, put into the mel...

Embodiment 3

[0043] Example 3: Preparation of transition metal crystallites doped chalcogenide glass composites

[0044] with Fe 2+ :ZnSe doped As 2 S 3 Taking glass as an example, the following steps are involved:

[0045] (1) The particle size of the FeSe powder is selected to be 2 μm, and the mass ratio is 0.05%. The particle size of the ZnSe powder is 1000 μm, and the mass ratio is 99.95%. Put the FeSe and ZnSe powders into a ball mill and stir for 12 hours to make the powders fully mixed evenly. Put the uniformly mixed powder into a quartz tube, place it in a furnace, and keep it at 850°C for 168 hours to obtain Fe 2+ : ZnSe material.

[0046] (2) Fe 2+ :ZnSe material and As 2 S 3 The glass is put into a ball mill, where Fe 2+ : The mass ratio of ZnSe material is 25%, and it is ground for 72 hours to prepare a uniformly mixed powder with a particle size of about 1 μm.

[0047] (3) Put the above mixed powder in a quartz tube and vacuumize to 1×10 -3 Pa, sealed, put into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com